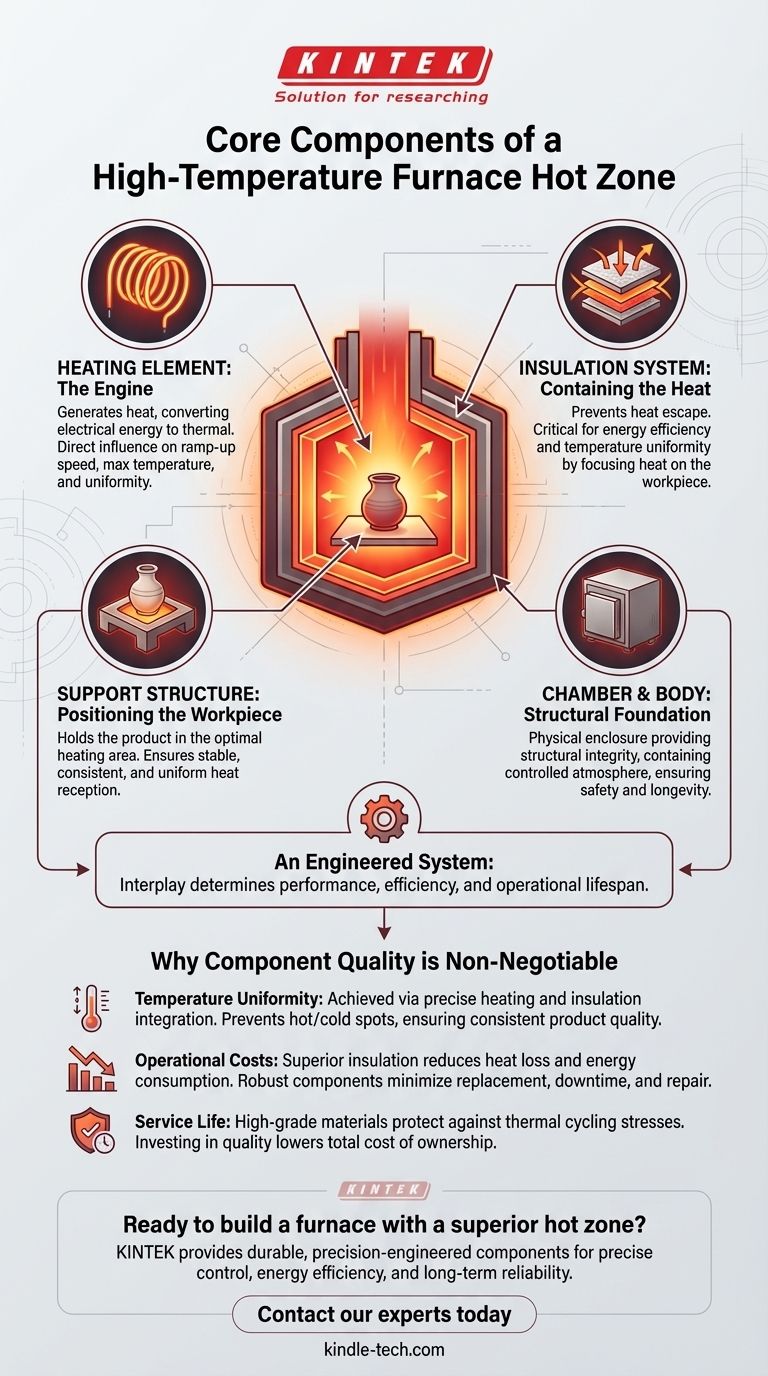

At its core, a high-temperature furnace hot zone consists of four primary components. These are the heating elements that generate the heat, the insulation system that contains it, the support structure that holds the workpiece, and the chamber or body that provides the structural foundation.

A hot zone is not merely a collection of parts; it is an engineered system where the quality and interplay of each component directly determine the furnace's performance, efficiency, and operational lifespan.

The Anatomy of a Furnace Hot Zone

Understanding a furnace begins with understanding the distinct role of each component within its hot zone. Each part is designed to solve a specific challenge related to generating and controlling extreme temperatures.

The Heating Element: The Engine of the Furnace

The heating element is the component responsible for converting electrical energy into thermal energy. The design and material quality of this element are critical for achieving target temperatures rapidly and uniformly.

The mass and material of the heating element directly influence the furnace's ramp-up speed and its maximum achievable temperature.

The Insulation System: Containing the Heat

Referred to as a heat insulation screen or simply insulation, this system is arguably the most critical for efficiency. Its job is to prevent heat from escaping the chamber.

High-quality insulation materials ensure that the energy generated by the heating elements is focused on the workpiece, not lost to the surrounding environment. This directly improves temperature uniformity and reduces energy consumption.

The Support Structure: Positioning the Workpiece

The support structure, often a frame or hearth, is what holds the product being heat-treated. It must be stable and capable of withstanding the furnace's maximum temperatures without degrading.

Its purpose is to place the product in the optimal heating area, ensuring it receives consistent and uniform heat from all sides.

The Chamber and Body: The Structural Foundation

The chamber (or body/housing) is the physical enclosure for the hot zone components. It provides structural integrity and contains the controlled atmosphere required for many high-temperature processes.

The quality of its construction ensures the longevity of the furnace and the safety of the operation.

Why Component Quality is Non-Negotiable

The selection of materials and the engineering of each component have a direct and significant impact on the outcome of the production process. A well-designed hot zone is the key to achieving repeatable, high-quality results.

The Impact on Temperature Uniformity

Temperature uniformity is a critical measure of a furnace's performance. It is achieved through the careful integration of powerful heating elements and a highly effective insulation system.

Poor component quality can lead to hot or cold spots within the chamber, resulting in inconsistent product quality.

The Link to Operational Costs

A superior insulation system reduces heat loss, which in turn lowers energy consumption and overall operating costs.

Furthermore, robustly built components, particularly heating elements and supports, reduce the frequency of replacement and maintenance, minimizing downtime and repair expenses.

The Influence on Service Life

The service life of a furnace is directly tied to the quality of its core components. Using high-grade materials for the chamber, insulation, and heating elements protects the entire system from the stresses of thermal cycling.

Investing in a quality hot zone from the outset lowers the total cost of ownership over the furnace's lifetime.

Making the Right Choice for Your Application

Your primary process goal should dictate your focus when evaluating a furnace hot zone.

- If your primary focus is process quality and repeatability: Prioritize a design with excellent temperature uniformity, which stems from advanced heating element design and multi-layer insulation.

- If your primary focus is minimizing operational costs: Emphasize the quality of the insulation for maximum energy efficiency and the durability of the heating elements to reduce maintenance needs.

- If your primary focus is long-term reliability: Scrutinize the build quality of the chamber, support structures, and all internal components to ensure a long service life.

Ultimately, understanding these core components empowers you to select a furnace that will reliably and efficiently meet your specific production demands.

Summary Table:

| Component | Primary Function | Key Impact |

|---|---|---|

| Heating Element | Generates heat | Temperature ramp-up speed and uniformity |

| Insulation System | Contains heat | Energy efficiency and temperature uniformity |

| Support Structure | Holds workpiece | Process consistency and product quality |

| Chamber/Body | Provides structure | Operational safety and furnace longevity |

Ready to build a furnace with a superior hot zone?

Choosing the right components is critical for achieving precise temperature control, maximizing energy efficiency, and ensuring long-term reliability in your lab. KINTEK specializes in high-performance lab equipment and consumables, providing the durable, precision-engineered components your laboratory needs for consistent, high-quality results.

Contact our experts today to discuss how we can help optimize your high-temperature processes and reduce your total cost of ownership.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Muffle Furnace Oven for Laboratory

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

People Also Ask

- How is a vacuum drying oven utilized in the preparation of NCM83 cathode electrodes? Ensure Peak Battery Performance

- What is quenching furnace? Achieve Precise Hardness & Strength in Metal Parts

- What is the role of a vacuum heating chamber? Protect Material Integrity During 12%Cr Steel Heat Treatment

- How the increased use of pyrolysis might affect the environment? Unlock a Circular Economy or Risk Pollution

- What role does a vacuum resistance furnace play in the diffusion chromizing of steel? Achieve 2.8mm Deep Bonding

- What is the arc melting technique? Master High-Purity Metal Melting for Refractory Alloys

- Why sintering is necessary after compaction? To Transform Weak Powder into a Strong, Durable Metal Part

- What temperature is needed for metal casting? Achieve Perfect Casts with the Right Superheat