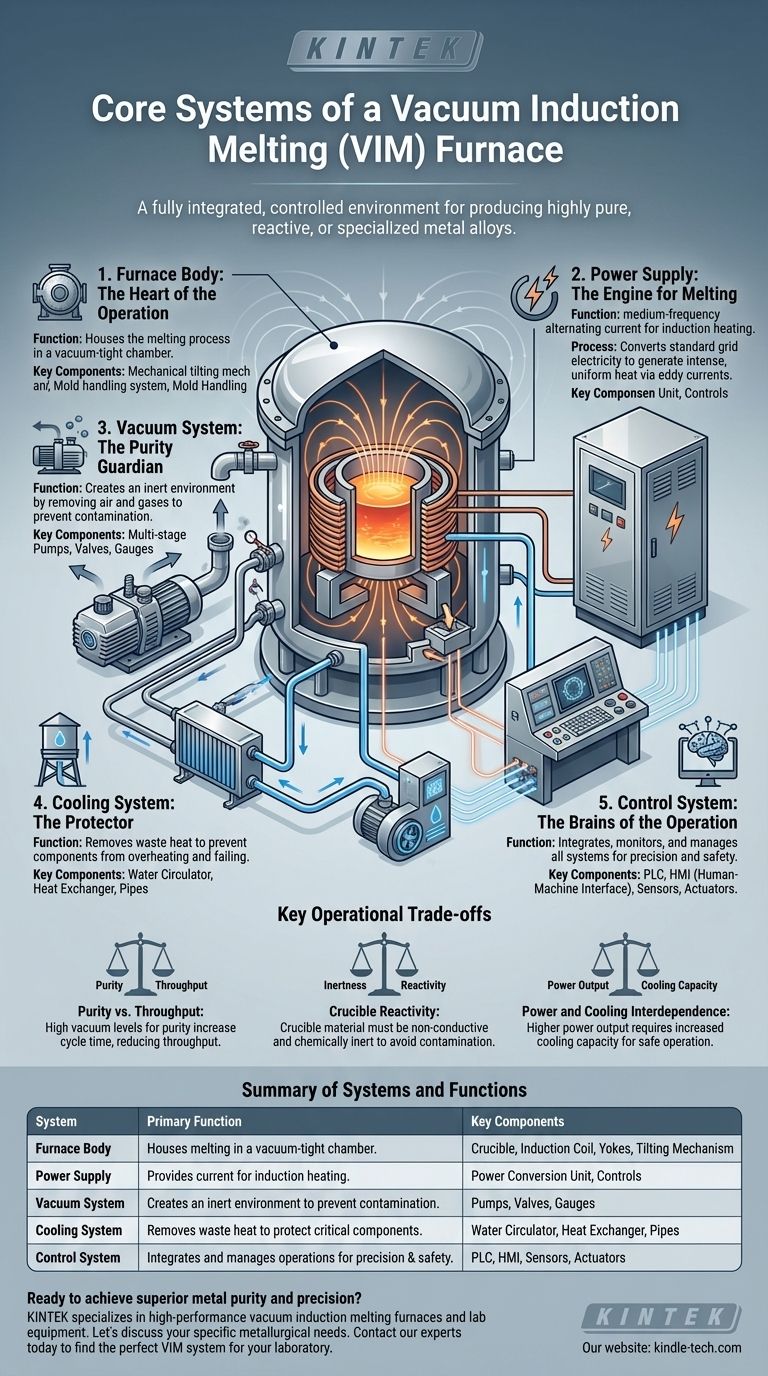

At its core, a vacuum induction melting (VIM) furnace is an integrated machine comprised of five primary systems. These are the furnace body (which houses the melting components), a medium-frequency power supply, a high-performance vacuum system, a critical water-cooling system, and a central electric control system that integrates their functions. Together, these systems create a tightly controlled environment for producing highly pure, reactive, or specialized metal alloys.

A VIM furnace isn't just a heater; it's a complete processing environment. It leverages electromagnetic induction for clean, contactless melting inside a vacuum chamber to prevent contamination, with essential support systems ensuring precision, operational safety, and final product quality.

The Core Systems of a VIM Furnace

Understanding a VIM furnace requires looking at how its main systems work in concert. Each system has a distinct role, but all are interdependent for the successful melting of high-specification metals.

The Furnace Body: The Heart of the Operation

The furnace body is the central vacuum-tight chamber that contains all the melting and casting hardware. It is the physical core where the entire metallurgical process takes place.

This chamber is equipped with several critical internal components:

- The Crucible: This is a non-conductive, refractory-lined container that holds the metal charge. The crucible material is carefully selected to withstand extreme temperatures and avoid reacting with the molten alloy.

- The Induction Coil: A water-cooled copper coil surrounds the crucible. When energized by the power supply, it generates a powerful, alternating magnetic field that is the key to the melting process.

- The Yokes: These magnetic shields are placed around the induction coil. Their job is to contain the magnetic field, focusing energy on the metal charge and protecting the furnace shell from stray heating.

- Mechanical Systems: The furnace body also includes mechanisms for tilting the entire assembly to pour molten metal, handling ingot molds, and introducing new material or taking samples through vacuum-sealed ports. These are often powered by hydraulic or pneumatic systems.

The Power Supply: The Engine for Melting

The power supply is the high-power unit that drives the induction coil. It converts standard grid electricity into the medium-frequency alternating current required for induction heating.

This system works by sending current through the induction coil, creating a fluctuating magnetic field. This field penetrates the metal inside the crucible and induces powerful circular electrical currents, known as eddy currents. The metal's natural electrical resistance causes these currents to generate intense, uniform heat, melting the charge from the inside out without any direct contact.

The Vacuum System: The Purity Guardian

The vacuum system is responsible for removing air and other gases from the furnace body before and during melting. Its primary purpose is to create an inert environment.

This is critical for preventing the hot, reactive molten metal from oxidizing or becoming contaminated by atmospheric gases like oxygen and nitrogen. A typical VIM vacuum system is a multi-stage setup, using powerful pumps to achieve the high vacuum levels necessary for producing clean, high-purity superalloys and specialty metals.

The Cooling System: The Protector

The immense electrical energy and heat involved in the VIM process necessitate a robust cooling system, almost always using circulating water.

This system's primary job is to remove waste heat from the most critical components. It continuously cools the induction coil, the power supply, and the vacuum chamber walls, preventing them from overheating and failing. An interruption in the cooling system would lead to a catastrophic failure of the furnace.

The Control System: The Brains of the Operation

The control system is the central nervous system that integrates, monitors, and manages all other systems.

From a central console, operators use the control system to manage power output, regulate vacuum levels, monitor temperatures, and actuate the mechanical tilting and pouring mechanisms. This system ensures the entire process runs safely, efficiently, and with the precision required to meet strict metallurgical specifications.

Understanding Key Operational Trade-offs

Simply knowing the components isn't enough; understanding their interplay reveals the trade-offs inherent in the VIM process.

Purity vs. Throughput

Achieving the highest vacuum levels for ultimate metal purity requires significant pumping time. This extends the duration of each melting cycle, which naturally reduces the overall production throughput. Furnaces can be designed as intermittent (batch) or semi-continuous to balance this trade-off based on production needs.

Crucible Reactivity

The choice of crucible material is a critical decision. While it must be non-conductive and withstand heat, it must also be chemically inert to the specific alloy being melted. A poor choice can lead to contamination as elements from the crucible leach into the molten metal, compromising the final product's integrity.

Power and Cooling Interdependence

The melting power cannot be considered in isolation. Any increase in power to melt faster or achieve higher temperatures generates more waste heat. This demands a proportional increase in the cooling system's capacity. These two systems are inextricably linked, and their balance dictates the furnace's safe operating limits.

Making the Right Choice for Your Goal

The emphasis placed on each system depends entirely on the desired outcome of the metallurgical process.

- If your primary focus is ultimate metal purity: Your investment must prioritize a high-performance, multi-stage vacuum system and the selection of the most non-reactive crucible material available for your alloy.

- If your primary focus is high-volume production: Look for a semi-continuous furnace design with robust, fast-acting mechanical systems for charging and mold handling to minimize cycle time.

- If your primary focus is complex alloy development: A sophisticated and precise control system, coupled with mechanisms for accurate material feeding and in-process sampling, is absolutely essential.

Understanding how these core systems interoperate is the key to mastering the vacuum induction melting process and achieving your specific material goals.

Summary Table:

| System | Primary Function | Key Components |

|---|---|---|

| Furnace Body | Houses the melting process in a vacuum-tight chamber. | Crucible, Induction Coil, Yokes, Tilting Mechanism |

| Power Supply | Provides medium-frequency current for induction heating. | Power Conversion Unit, Controls |

| Vacuum System | Creates an inert environment to prevent contamination. | Pumps, Valves, Gauges |

| Cooling System | Removes waste heat to protect critical components. | Water Circulator, Heat Exchanger, Pipes |

| Control System | Integrates and manages all operations for precision and safety. | PLC, HMI, Sensors, Actuators |

Ready to achieve superior metal purity and precision?

KINTEK specializes in high-performance vacuum induction melting furnaces and lab equipment. Whether your goal is ultimate purity for superalloys, high-volume production, or complex alloy development, our solutions are engineered for reliability and exacting results.

Let's discuss your specific metallurgical needs. Contact our experts today to find the perfect VIM system for your laboratory.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the primary functions of an induction furnace lining? Essential Safety & Efficiency Roles in Metal Melting

- What are the reactions in an induction furnace? Mastering Metallurgical Control for Your Melt

- What are the energy conversions in induction furnaces? Mastering the Physics of Efficient Heating

- What is the furnace used to melt gold? Discover the Clean, Fast Induction Method

- What is the highest temperature for an induction furnace? Unlocking 2000°C for High-Purity Melting

- How does an Inductotherm furnace work? Harnessing Electromagnetic Induction for Efficient Metal Melting

- What are the three stages of the induction furnace lining sintering process? Master Your Furnace Longevity

- What is the temperature range of induction heating? From Gentle Warming to Extreme Melting