For a vacuum furnace's hot zone, the most frequently used metals are molybdenum and its specialized alloys. These materials are selected for their ability to withstand extreme temperatures while maintaining purity within the vacuum environment.

The choice of metal for a vacuum furnace hot zone is not just about heat resistance; it's a critical decision that directly impacts process purity, temperature uniformity, and the quality of the final product. Molybdenum is the cornerstone material for its balance of performance and reliability.

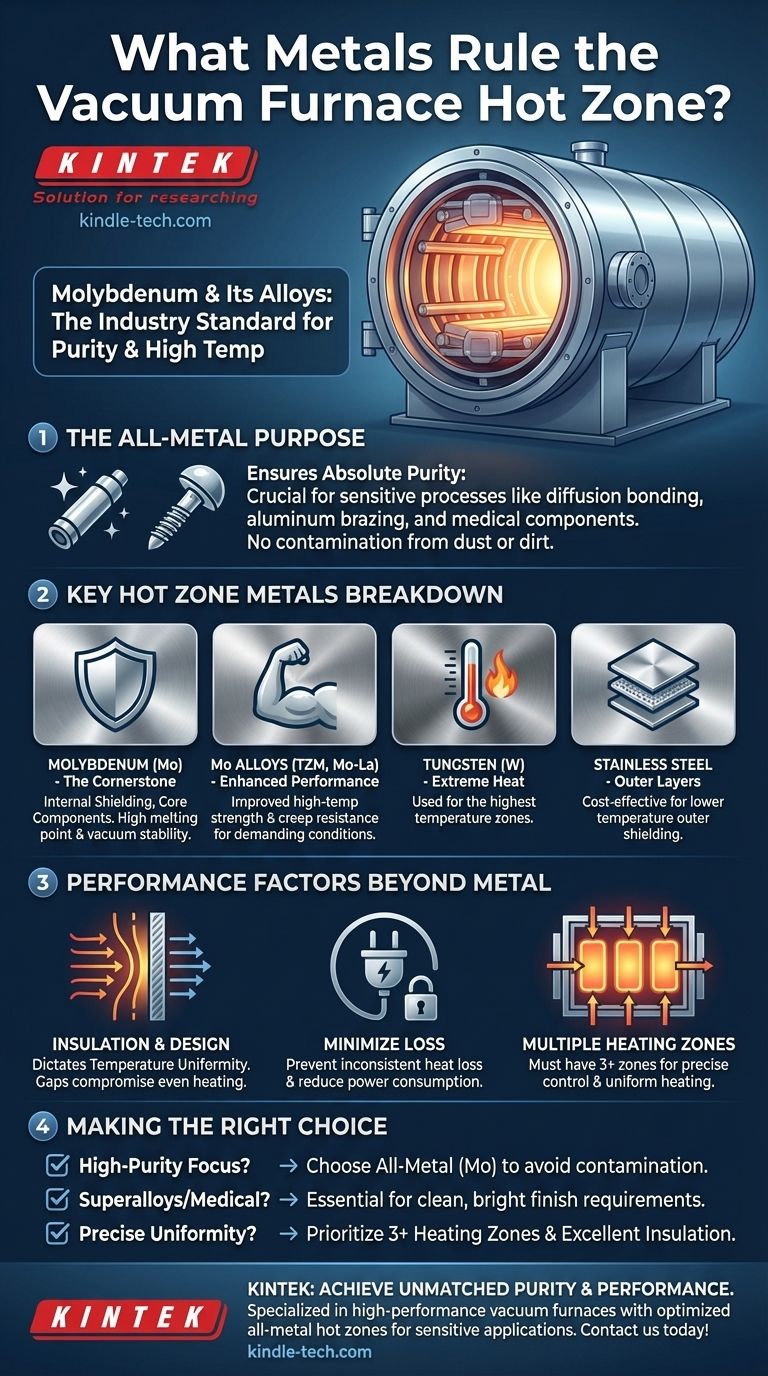

The Purpose of an All-Metal Hot Zone

An all-metal hot zone is engineered for processes where cleanliness is paramount. It creates a controlled environment free from the incidental dust or dirt that can be shed by other insulation types, like graphite.

Ensuring Absolute Purity

Certain applications cannot tolerate any level of contamination. An all-metal construction produces parts that are bright and clean, a non-negotiable requirement in sectors like the medical industry.

Processing Sensitive and Advanced Materials

This design is the best option for sensitive processes such as diffusion bonding and aluminum brazing. It is also essential for working with advanced superalloys like Titanium, Hastealloy, and nickel-based alloys.

A Breakdown of Key Hot Zone Metals

While several metals can be used, a few dominate the industry due to their specific properties under vacuum and high heat.

Molybdenum (Mo): The Industry Standard

Molybdenum is the most typical material used for the internal shielding and components of conventional all-metal hot zones. Its high melting point and stability in a vacuum make it the default choice for many applications.

Molybdenum Alloys: Enhancing Performance

For more demanding conditions, specialized alloys are used. The most common are TZM alloy (Titanium-Zirconium-Molybdenum) and molybdenum-lanthanum alloy, which offer improved high-temperature strength and creep resistance over pure molybdenum.

Tungsten and Stainless Steel: Supporting Roles

While molybdenum forms the core, other metals play a part. Tungsten may be used for even higher temperature applications, and stainless steel is often used in the outer layers of the shielding package where temperatures are lower.

Factors That Dictate Performance

Simply choosing the right metal is not enough. The overall design and construction of the hot zone are critical for achieving the desired results.

The Impact of Insulation Design

Temperature uniformity is primarily dictated by the insulation design. Any unacceptable gaps or poorly designed openings, especially for gas flow ports, can compromise the furnace's ability to heat a part evenly.

Minimizing Heat and Power Loss

The correct selection and assembly of materials are crucial for minimizing power losses and preventing inconsistent heat loss from the front to the back of the furnace.

The Necessity of Multiple Heating Zones

To achieve precise temperature control, a well-designed hot zone must have a minimum of three distinct heating zones. This allows for fine-tuning and adjustment of power input to ensure uniform heating across the entire workload.

Making the Right Choice for Your Application

Selecting the correct materials is the foundation for a reliable and efficient vacuum furnace capable of operating at temperatures up to 5250°F (2899°C) and higher.

- If your primary focus is high-purity processing: An all-metal hot zone, typically constructed with molybdenum, is the best option to avoid contamination.

- If your primary focus is working with superalloys or medical components: The clean and bright finish provided by an all-metal hot zone is essential for meeting industry requirements.

- If your primary focus is achieving precise temperature uniformity: You must prioritize a design with excellent insulation integrity and at least three distinct heating zones.

Ultimately, a furnace's performance is a direct result of the synergy between its materials and its engineering design.

Summary Table:

| Metal / Alloy | Key Property | Common Application in Hot Zone |

|---|---|---|

| Molybdenum (Mo) | High melting point, stability in vacuum | Internal shielding, core components |

| TZM Alloy | Enhanced high-temperature strength & creep resistance | Demanding high-temperature applications |

| Molybdenum-Lanthanum Alloy | Improved high-temperature performance | Specialized high-temperature components |

| Tungsten | Highest temperature resistance | Extreme temperature zones |

| Stainless Steel | Cost-effective, good for lower temperatures | Outer shielding layers |

Achieve Unmatched Purity and Performance in Your Lab

Selecting the right hot zone materials is critical for process success. KINTEK specializes in providing high-performance lab equipment, including vacuum furnaces with optimized all-metal hot zones for sensitive applications like diffusion bonding, aluminum brazing, and superalloy processing.

Our expertise ensures your furnace delivers the temperature uniformity and contamination-free environment your work demands. Contact us today to discuss your specific needs and how our solutions can enhance your lab's capabilities.

Get in touch with our experts now!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What is the temperature range of a vacuum furnace? From 500°C to 2200°C for Your Specific Process

- How do vacuum furnaces heat? Achieve Purity and Precision in High-Temperature Processing

- What is the role of an arc-melting furnace in the synthesis of uranium silicide? Master Nuclear Fuel Composition

- How does a high-temperature sintering furnace facilitate the creation of open-cell structures? Master the SEP Process

- How do annular steam pipes improve activation furnace efficiency? Maximize Carbon Reaction Rates and Quality

- How does a vacuum drying oven contribute to the preparation of LNMO battery electrodes? Achieve Optimal Stability

- Why is a high-temperature annealing furnace used for 316L steel pre-treatment? Ensure High-Energy Pulse Accuracy

- What is the function of a sintering furnace? Transform Powders into High-Performance Solid Parts