At its core, annealing is a process of controlled healing for materials. It is a precise heat treatment used to solve specific problems created during manufacturing, primarily by relieving internal stresses, reducing hardness, and increasing ductility. By carefully heating a material to a specific temperature, holding it there, and then slowly cooling it, annealing effectively resets its internal structure, making it more uniform and workable.

The fundamental need for annealing is to reverse the damaging effects of manufacturing processes like casting, welding, or cold working. It doesn't just soften a material; it repairs the internal crystalline structure to eliminate hidden stresses and restore the ductility required for further fabrication or reliable service.

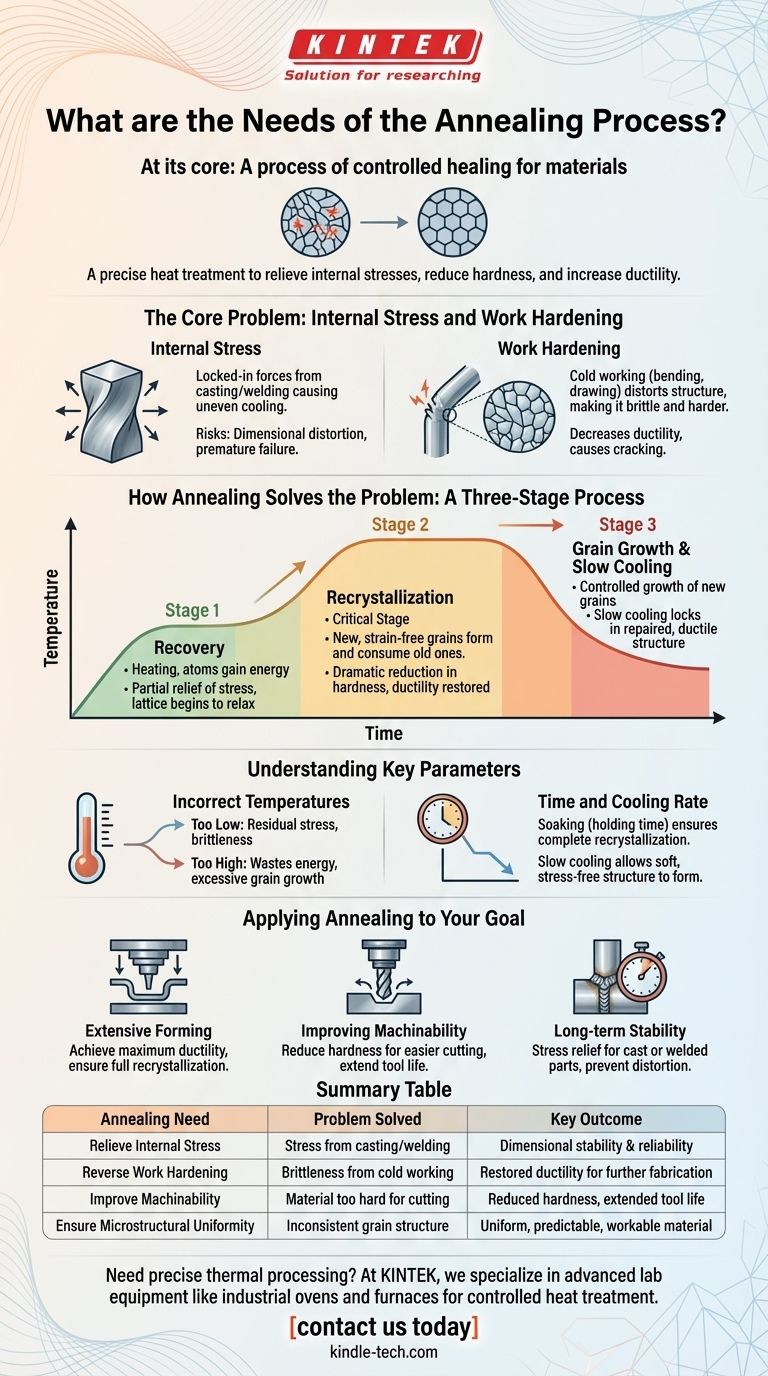

The Core Problem: Internal Stress and Work Hardening

To understand the need for annealing, you must first understand the problems it solves. These issues are created at the microscopic level during common manufacturing operations.

What is Internal Stress?

Internal stresses are locked-in forces within a material. Processes like casting, where molten material cools unevenly, or welding, which creates intense localized heat, cause different parts of the material to pull against each other.

These hidden stresses are a significant liability. They can lead to dimensional distortion over time or, more critically, cause unexpected and premature failure when the part is put into service.

Understanding Work Hardening

When you bend, draw, or form a metal at room temperature (a process called cold working), you are distorting its internal crystal structure. This makes the material harder and stronger, but also significantly more brittle.

As work hardening increases, the material's ability to be formed further—its ductility—decreases. Eventually, it becomes so brittle that any additional attempt to shape it will cause it to crack or fracture.

How Annealing Solves the Problem: A Three-Stage Process

Annealing systematically reverses these issues by taking the material through three distinct stages as the temperature is increased.

Stage 1: Recovery

As the material is heated, the atoms gain thermal energy. This initial phase allows for the partial relief of internal stresses as the distorted crystal lattice begins to relax. The material's properties, however, are not yet significantly changed.

Stage 2: Recrystallization

This is the most critical stage of annealing. As the material reaches its target temperature, new, strain-free crystals (or "grains") begin to form within the old, distorted structure.

These new grains grow and eventually consume the old ones, effectively replacing the damaged, work-hardened microstructure with a new, ductile one. This is the point where hardness is dramatically reduced and ductility is restored.

Stage 3: Grain Growth

If the material is held at the recrystallization temperature for too long, the new, strain-free grains will begin to merge and grow larger. This final stage must be carefully controlled.

While it ensures all stress is removed, excessive grain growth can sometimes negatively impact certain mechanical properties, such as toughness. The slow cooling that follows "locks in" this new, repaired, and ductile structure.

Understanding the Trade-offs and Key Parameters

Annealing is a precise science, not a brute-force heating process. Success depends entirely on controlling the variables to achieve a specific outcome.

The Risk of Incorrect Temperatures

Heating the material to a temperature that is too low will prevent full recrystallization, leaving behind residual stress and brittleness. Heating it too high wastes energy and can initiate unwanted grain growth, potentially harming the final properties.

The Critical Role of Time and Cooling Rate

The material must be held at the target temperature—a step known as soaking—for a sufficient period to ensure the recrystallization process is complete throughout the entire part.

Furthermore, the rate of cooling is crucial. The slow, controlled cooling associated with annealing is what allows a soft, stress-free, and uniform microstructure to form. Different cooling rates can produce vastly different results.

Applying Annealing to Your Goal

Use annealing as a targeted solution based on your specific engineering need.

- If your primary focus is preparing a material for extensive forming: The goal is to achieve maximum ductility by ensuring full recrystallization, which erases the effects of any prior work hardening.

- If your primary focus is improving the machinability of an alloy: The goal is to reduce hardness to a level that makes cutting easier and extends tool life, balancing workability with final part requirements.

- If your primary focus is ensuring the long-term stability of a cast or welded part: The goal is stress relief, eliminating the hidden internal forces that could lead to distortion or failure in service.

By understanding these principles, you can specify annealing not just as a step, but as a precise tool to engineer the exact material properties your project demands.

Summary Table:

| Annealing Need | Problem Solved | Key Outcome |

|---|---|---|

| Relieve Internal Stress | Stress from casting/welding causing distortion/failure | Dimensional stability & reliability |

| Reverse Work Hardening | Brittleness from cold working (bending, drawing) | Restored ductility for further fabrication |

| Improve Machinability | Material too hard for efficient cutting | Reduced hardness, extended tool life |

| Ensure Microstructural Uniformity | Inconsistent internal grain structure | A uniform, predictable, and workable material |

Need precise thermal processing to achieve the perfect material properties for your project?

At KINTEK, we specialize in advanced lab equipment, including industrial ovens and furnaces, designed for controlled heat treatment processes like annealing. Whether you're working on R&D, quality control, or production, our solutions help you relieve internal stresses, restore ductility, and ensure material reliability.

Let our experts help you select the right equipment to meet your specific annealing needs—contact us today to discuss your application!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan