Immediately after use, a platinum mesh electrode must be rinsed thoroughly with deionized water to remove residual electrolyte. It should then be fully dried, either by air or in a low-temperature oven, and stored in a clean, dry container with the delicate mesh facing upwards to prevent damage to its connection point.

The core principle behind maintaining a platinum electrode is not just cleaning; it is about preserving its high surface area and catalytic activity. Your post-use protocol should focus on preventing both physical damage and chemical contamination, which are the primary causes of performance degradation and inaccurate results.

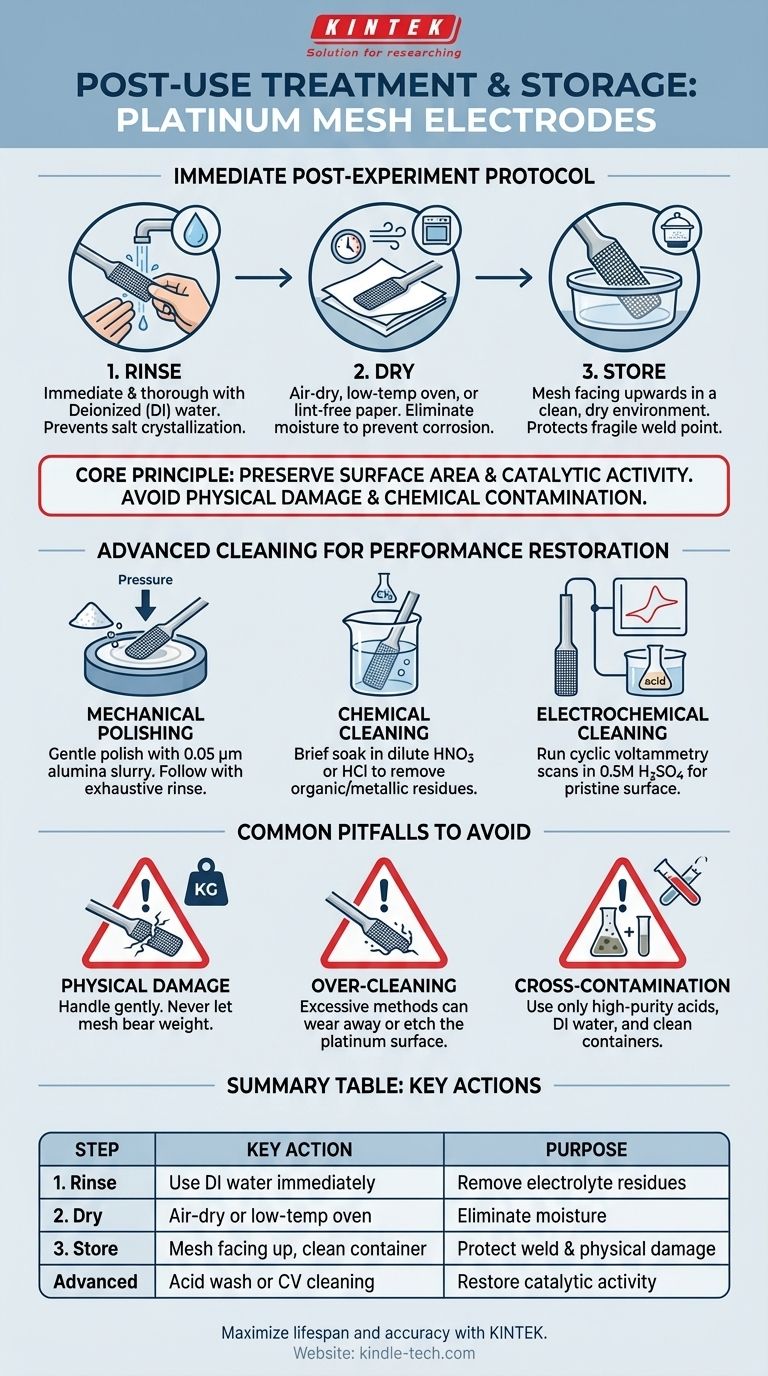

The Immediate Post-Experiment Protocol

Properly executing these three steps immediately after every use is the most critical factor in extending the life and ensuring the accuracy of your electrode.

Step 1: Immediate Rinsing

The most crucial step is to rinse the electrode the moment you remove it from the electrolyte solution.

Use deionized (DI) or distilled water for this purpose. A thorough rinse prevents residual electrolyte salts from crystallizing on the platinum surface, which can be difficult to remove later and can interfere with future experiments.

Step 2: Thorough Drying

Moisture is a catalyst for contamination and corrosion. Ensure the electrode is completely dry before storing it.

You have a few options: allow it to air-dry in a clean environment, use a low-temperature oven, or gently blot the surface with clean, lint-free filter paper. Avoid high heat, which can stress the materials.

Step 3: Secure and Correct Storage

How you store the electrode is as important as how you clean it. The goal is to protect it from both physical and chemical harm.

Store the electrode in a dry, clean, non-contaminating environment, such as a dedicated electrode box or a desiccator. The original packaging is often ideal. Always position the electrode with the platinum mesh facing upwards to avoid putting stress on the fragile weld at the connection point.

Advanced Cleaning for Performance Restoration

Over time, simple rinsing may not be enough to remove stubborn contaminants. If you notice inconsistent results or visible residue, a deeper cleaning is necessary.

When to Consider a Deeper Clean

Proceed with advanced methods only when performance is compromised. Signs include drifting potentials, poor cyclic voltammograms, or a visible film on the electrode surface.

Mechanical Polishing

For stubborn physical deposits, you can polish the surface using a slurry of 0.05 µm alumina powder on a polishing pad.

Use gentle pressure, as the platinum mesh is delicate and can be damaged easily. Always follow polishing with an exhaustive rinse with deionized water to remove all alumina particles.

Chemical Cleaning (Acid Washing)

Soaking the electrode in a dilute acid can effectively remove organic residues and some metallic impurities.

Common choices include dilute nitric acid (HNO₃) or hydrochloric acid (HCl). A brief soak followed by a thorough DI water rinse is typically sufficient.

Electrochemical Cleaning

This is the most effective method for restoring a pristine, catalytically active platinum surface.

This process involves running cyclic voltammetry scans on the electrode in a clean acid solution, typically 0.5M sulfuric acid (H₂SO₄). The scans oxidatively and reductively strip contaminants from the surface until a stable, textbook platinum voltammogram is achieved.

Common Pitfalls to Avoid

Understanding the risks associated with electrode care is key to preventing irreversible damage.

The Risk of Physical Damage

Platinum electrodes, particularly mesh and wire types, are extremely fragile. The weld connecting the platinum to the support rod is a common point of failure. Always handle the electrode gently and never let the mesh bear any weight or impact.

The Danger of Over-Cleaning

While advanced cleaning methods are powerful, they are also aggressive. Excessive mechanical polishing can wear away the platinum, and repeated, harsh chemical treatments can slowly etch the surface. Reserve these methods for when they are truly necessary.

The Problem of Cross-Contamination

Using dirty glassware or impure reagents for cleaning defeats the purpose. Always use high-purity acids and DI water, and ensure all beakers and containers are scrupulously clean to avoid introducing new contaminants onto your electrode surface.

Making the Right Choice for Your Goal

Your maintenance strategy should adapt to your usage patterns and experimental needs.

- If your primary focus is routine daily experiments: The immediate rinse-and-dry protocol is sufficient and should be performed consistently after every use.

- If your primary focus is high-sensitivity analysis: Incorporate a periodic electrochemical cleaning into your protocol to ensure the platinum surface is in a perfectly defined and active state before critical measurements.

- If your primary focus is long-term storage: Ensure the electrode is impeccably clean and perfectly dry before placing it in a secure, sealed container to prevent atmospheric contamination or accidental damage.

Consistent, gentle care is the key to ensuring your platinum electrode delivers reliable and repeatable results for years to come.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Rinse | Use deionized water immediately after use. | Remove electrolyte residues to prevent crystallization. |

| 2. Dry | Air-dry or use a low-temperature oven. | Eliminate moisture to avoid contamination and corrosion. |

| 3. Store | Place in a clean, dry container with mesh facing up. | Protect the delicate weld point and prevent physical damage. |

| Advanced Clean | Use acid wash or electrochemical cleaning as needed. | Restore catalytic surface activity for high-sensitivity work. |

Maximize the lifespan and accuracy of your laboratory electrodes with KINTEK.

Your research depends on reliable data, and proper equipment care is fundamental to achieving it. The detailed protocols above highlight the critical importance of consistent, gentle maintenance for platinum electrodes.

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including durable electrodes designed for precision and longevity. Our expertise supports laboratories in maintaining their instruments for peak performance.

Let us help you protect your investment and ensure experimental repeatability. Contact our experts today to discuss your specific electrode needs and discover how KINTEK's solutions can enhance your lab's efficiency and data quality.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Metal Disc Electrode Electrochemical Electrode

- Gold Disc Electrode

People Also Ask

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data

- What are the performance characteristics of platinum sheet electrodes? Unlock Superior Electrochemical Performance

- How should a platinum sheet electrode be pretreated before use? Ensure Accurate Electrochemical Measurements

- What is the expected lifespan of a platinum sheet electrode? Maximize Your Electrode's Service Life