At its core, a crucible is defined by its ability to withstand extreme conditions. Its essential properties are an exceptionally high melting point, outstanding chemical and physical stability, and complete inertness to the materials it contains. These characteristics ensure it can securely hold molten substances without failing, reacting with the contents, or contaminating the final product.

The ideal properties of a crucible are not universal; they are a direct function of the material being processed and the operating temperature. The central challenge is not finding the "best" crucible, but matching its material, design, and capabilities to the specific demands of your application.

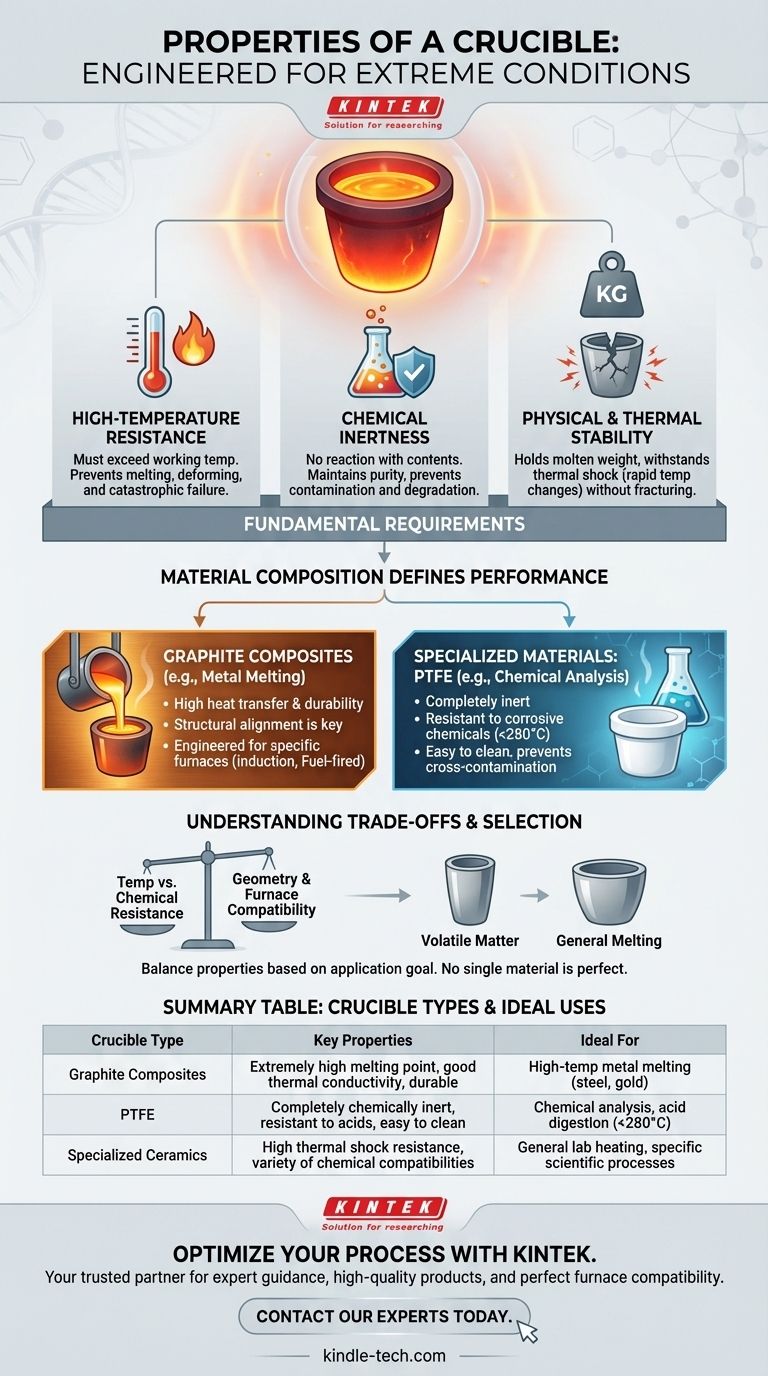

The Fundamental Requirements of Any Crucible

Every crucible, regardless of its specific use, is built upon a foundation of three non-negotiable properties. These ensure its basic function and safety.

High-Temperature Resistance

This is the most critical property. A crucible's melting point must be significantly higher than the working temperature of the material it is designed to hold.

This prevents the crucible itself from melting, deforming, or failing during the heating process, which would result in a catastrophic loss of containment.

Chemical Inertness

A crucible must be chemically compatible with the substance being melted. It cannot react with, dissolve into, or otherwise contaminate the melt.

This property is crucial for maintaining the purity of the final product and preventing the chemical degradation of the crucible, which would shorten its lifespan.

Physical and Thermal Stability

The material must be strong enough to hold the weight of molten materials without cracking or changing shape.

It must also withstand thermal shock—the stress of rapid temperature changes—without fracturing. This is vital when a crucible is placed into a hot furnace or when molten material is poured out.

How Material Composition Defines Performance

The fundamental requirements are met through careful selection of materials. Modern crucibles are often highly engineered composites tailored for specific tasks.

The Role of Graphite Composites

Many modern crucibles used for melting metals are graphite-based composites. They are not pure graphite but heterogeneous materials where composition and structure are precisely controlled.

The performance of these crucibles—their heat transfer, durability, and resistance—relies on the specific material blend and the structural alignment of the graphite within the composite.

Specialized Materials: PTFE

For applications where extreme chemical resistance is more important than high-temperature tolerance, other materials are used. PTFE crucibles are a prime example.

These are completely inert and can be used with highly corrosive chemicals up to 280°C. Their smooth, machine-finished surfaces also make them easy to clean and prevent cross-contamination in laboratory settings.

Understanding the Trade-offs

Selecting a crucible always involves balancing competing properties. There is no single material that is perfect for every situation.

Temperature vs. Chemical Resistance

A graphite composite crucible built for melting steel at over 1500°C will not have the same level of chemical inertness as a PTFE crucible used for acid digestion at 250°C. Each is specialized for its operating environment.

Application-Specific Geometry

The shape and size of a crucible are functional properties, not just matters of capacity. Different industrial and scientific processes demand different geometries.

For example, a tall, narrow "volatile matter" crucible is designed to limit air exposure during specific tests, while a wide, standard-form crucible is better for general melting and observation.

Furnace Compatibility

The crucible material must be compatible with the heating method. Crucibles are designed for specific furnace types, including fuel-fired, electric resistance, and induction furnaces. Using the wrong type can lead to inefficient heating or even catastrophic failure.

Selecting the Right Crucible for Your Application

Choosing the correct crucible requires a clear understanding of your primary goal. The material, shape, and size must be aligned with your process.

- If your primary focus is high-temperature metal melting: Prioritize a graphite-based composite crucible specifically engineered for your furnace type (e.g., induction or fuel-fired).

- If your primary focus is aggressive chemical analysis at lower temperatures: A PTFE or similar highly inert polymer crucible is the superior and safer choice.

- If your primary focus is a specific scientific process: Select a crucible with the precise geometry required for that application, such as a volatile matter crucible for coal analysis.

Understanding these core properties allows you to select a crucible not just as a container, but as a critical component engineered for your specific process.

Summary Table:

| Crucible Type | Key Properties | Ideal For |

|---|---|---|

| Graphite Composites | Extremely high melting point, good thermal conductivity, durable | High-temperature metal melting (e.g., steel, gold) |

| PTFE | Completely chemically inert, resistant to corrosive acids, easy to clean | Chemical analysis, acid digestion at lower temperatures (<280°C) |

| Specialized Ceramics | High thermal shock resistance, variety of chemical compatibilities | General lab heating, specific scientific processes |

Optimize Your Process with the Perfect Crucible

Selecting the right crucible is critical for the safety, efficiency, and purity of your work. The wrong choice can lead to contamination, equipment failure, and inaccurate results.

KINTEK is your trusted partner for all laboratory equipment and consumables. We specialize in helping labs like yours select the ideal crucible based on your specific application, whether it's high-temperature metal melting or aggressive chemical analysis.

We provide:

- Expert Guidance: Our specialists will help you navigate the trade-offs between temperature, chemical resistance, and geometry.

- High-Quality Products: From robust graphite composites for foundries to inert PTFE crucibles for analytical labs.

- Furnace Compatibility: Ensure your crucible is perfectly matched to your fuel-fired, electric, or induction furnace.

Don't leave your process to chance. Contact our experts today for a personalized consultation and ensure you have the right crucible for the job.

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- What are the advantages of using high-purity alumina crucibles for sintering? Ensure Material Purity and Integrity

- What are the disadvantages of a crucible furnace? Understanding Capacity, Cost, and Efficiency Limits

- What are the different types of crucibles? Find the Perfect Match for Your Melting Application

- Why are alumina crucibles selected as containers for liquid lead corrosion experiments? Ensure Pure Experimental Data

- What role does a Quartz Crucible play in carbochlorination? Ensure Elemental Purity in Rare Earth Extraction

- What is difference between crucible and furnace? Understand the Heat Source vs. Containment Vessel

- What is a crucible furnace used for melting of? Melt Non-Ferrous Metals from Aluminum to Gold

- What is the function of a graphite crucible in the FFC process? Key to High-Entropy Alloy Production