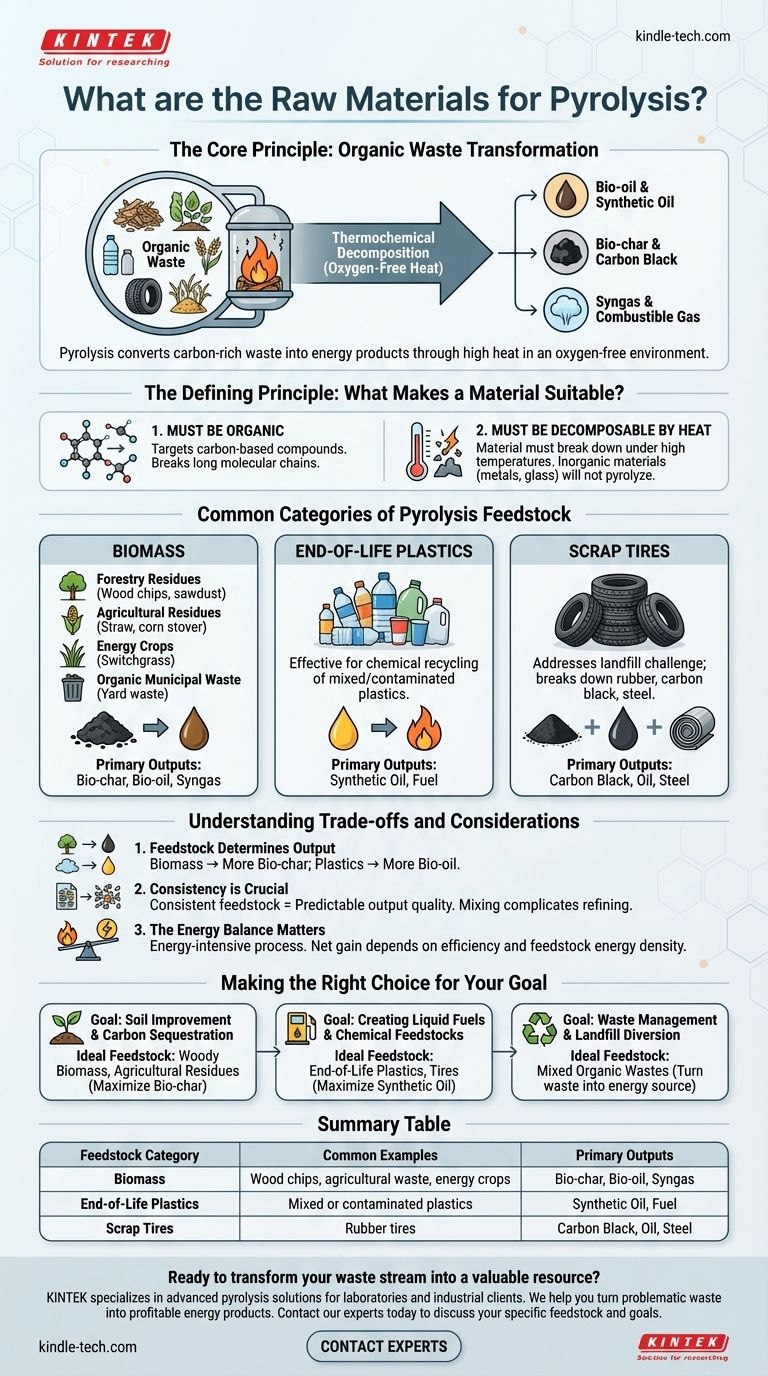

In essence, the raw materials for pyrolysis are any organic materials, especially carbon-rich waste streams that can be broken down by heat. This process is highly versatile, capable of converting a wide range of feedstocks including biomass (like wood and agricultural waste), end-of-life plastics, and scrap tires into valuable energy products.

The core principle of pyrolysis is not about a specific ingredient, but about a chemical transformation. It leverages high heat in an oxygen-free environment to unlock the stored energy within virtually any carbon-based material, turning problematic waste into a valuable resource.

The Defining Principle: What Makes a Material Suitable?

Pyrolysis is a process of thermochemical decomposition. This means the suitability of a raw material, or "feedstock," is determined by its chemical makeup, not just its physical form.

It Must Be Organic

The process specifically targets organic, carbon-based compounds. Pyrolysis works by breaking the long, complex molecular chains found in these materials (like cellulose in wood or polymers in plastic) into smaller, simpler molecules.

This is why pyrolysis is a form of thermolysis (decomposition by heat) and is one of the key processes involved in charring.

It Must Be Decomposable by Heat

The material must be able to break down under high temperatures. Inorganic materials like metals, glass, or rock will not pyrolyze; they will either melt or remain as solid contaminants in the final output.

Common Categories of Pyrolysis Feedstock

While the range of potential materials is vast, most industrial applications focus on a few key waste streams where the process offers significant environmental and economic advantages.

Biomass

This is one of the most common categories and includes a wide variety of plant-based materials. Examples include:

- Forestry Residues: Wood chips, sawdust, and bark.

- Agricultural Residues: Straw, corn stover, and rice husks.

- Energy Crops: Plants grown specifically for energy conversion, like switchgrass.

- Organic Municipal Waste: Yard waste and waste wood.

End-of-Life Plastics

Pyrolysis is an extremely effective method for chemical recycling, especially for mixed or contaminated plastics that are difficult to recycle mechanically. It breaks the plastic polymers back down into a liquid synthetic oil, which can be refined into new plastics or fuels.

Scrap Tires

Tires represent a significant landfill challenge. Pyrolysis can cleanly and efficiently break down the rubber, carbon black, and steel components into valuable outputs like synthetic oil, combustible gas, and a solid carbon residue (char).

Understanding the Trade-offs and Considerations

While pyrolysis is highly versatile, its effectiveness is not universal for all materials. Understanding the limitations is key to a successful application.

Feedstock Determines the Output

The specific chemical composition of the raw material directly influences the final products. A woody biomass will produce more bio-char (a solid carbon residue), while plastics will yield a much higher percentage of bio-oil (a liquid fuel).

Consistency is Crucial

A consistent, homogenous feedstock leads to a predictable and stable output. Mixing different types of waste (e.g., wood and plastic) without proper management can result in inconsistent product quality and complicate the refining process.

The Energy Balance Matters

Pyrolysis is an energy-intensive process. It requires a significant amount of heat to initiate and sustain the decomposition. The net energy gain depends entirely on the efficiency of the system and the energy density of the feedstock being processed.

Making the Right Choice for Your Goal

The ideal raw material depends entirely on your objective. The feedstock is not just an input; it's the primary variable that defines the output.

- If your primary focus is soil improvement and carbon sequestration: Use woody biomass or agricultural residues to maximize the production of stable, high-quality bio-char.

- If your primary focus is creating liquid fuels or chemical feedstocks: Prioritize end-of-life plastics and tires, as they yield a much higher volume of valuable synthetic oil.

- If your primary focus is waste management and landfill diversion: The technology can be adapted to a broader range of mixed organic wastes, turning a disposal problem into an energy source.

Ultimately, selecting the right raw material is about strategically matching an available waste stream to the most valuable and desirable output for your specific application.

Summary Table:

| Feedstock Category | Common Examples | Primary Outputs |

|---|---|---|

| Biomass | Wood chips, agricultural waste, energy crops | Bio-char, Bio-oil, Syngas |

| End-of-Life Plastics | Mixed or contaminated plastics | Synthetic Oil, Fuel |

| Scrap Tires | Rubber tires | Carbon Black, Oil, Steel |

Ready to transform your waste stream into a valuable resource?

KINTEK specializes in advanced pyrolysis solutions for laboratories and industrial clients. Whether you're processing biomass, plastics, or tires, our equipment is designed for efficiency and maximum yield. We help you turn problematic waste into profitable energy products like bio-oil and bio-char.

Contact our experts today to discuss your specific feedstock and goals. Let's build a sustainable solution together.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

People Also Ask

- What are the disadvantages of flash pyrolysis oil? Overcoming Key Challenges in Bio-Oil Utilization

- What is the future potential of pyrolysis and gasification? Unlocking Value from Waste

- Which ores undergo calcination? A Guide to Carbonate and Hydrated Ore Processing

- What is the temperature range for fast pyrolysis? Optimize Bio-Oil Yield from Biomass

- What is the disadvantage of pyrolysis? Key Economic and Technical Challenges Explained

- What are the uses of pyrolysis machine? Turn Waste into Fuel, Chemicals, and Soil Amendment

- What type of plastic is best for pyrolysis? Maximize Oil Yield and Quality with Polyolefins

- What is pyrolysis of biomass to produce hydrogen? A Guide to Carbon-Negative Green Hydrogen