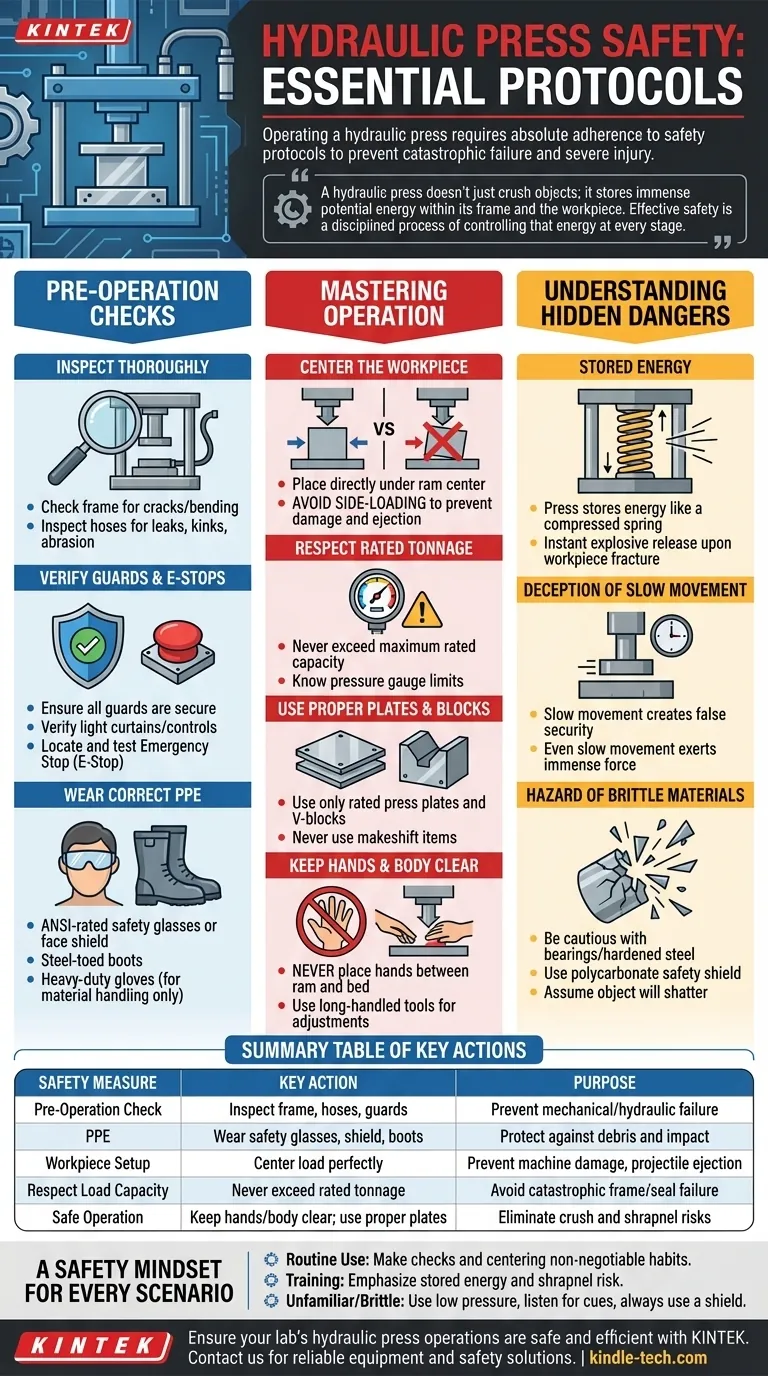

Operating a hydraulic press requires absolute adherence to safety protocols. The immense force generated by these machines can cause catastrophic equipment failure and severe injury if not respected. Key safety measures include a thorough pre-operation inspection, wearing correct Personal Protective Equipment (PPE), ensuring the workpiece is perfectly centered, never exceeding the press's rated load capacity, and always keeping your hands and body out of the press area during operation.

A hydraulic press doesn't just crush objects; it stores immense potential energy within its frame and the workpiece. Effective safety is not a simple checklist, but a disciplined process of controlling that energy at every stage—from inspection to the final release of pressure.

The Foundation of Safety: Pre-Operation Checks

Before any power is applied, a systematic inspection is your first and most critical line of defense against accidents. Rushing this step exposes you to mechanical and hydraulic failures.

Inspect the Machine Thoroughly

Check the entire frame of the press for any signs of stress, such as cracks or bending, particularly around welded joints. Inspect all hydraulic lines for leaks, kinks, or visible abrasion. A leaking hose is not just a slip hazard; it is a sign of a system under strain that could burst.

Verify Safety Guards and E-Stops

Ensure all physical guards are in place and secure. If the press is equipped with light curtains or two-hand controls, verify they are functioning correctly. Locate the emergency stop (E-Stop) button and ensure it is unobstructed and works as intended.

Wear Correct Personal Protective Equipment (PPE)

The minimum required PPE is non-negotiable. Always wear ANSI-rated safety glasses or, preferably, a full face shield to protect against flying debris. Steel-toed boots protect your feet from falling objects, and heavy-duty gloves can prevent cuts and pinch points when handling materials.

Mastering the Pressing Operation

During operation, your focus must be on controlling the immense forces at play. Complacency is the primary cause of incidents.

Center the Workpiece Flawlessly

The workpiece must be placed directly in the center of the press bed, under the middle of the ram. Applying force to an off-center object—known as side-loading—can bend the ram, damage the press frame, and cause the workpiece to violently eject from the machine.

Respect the Rated Tonnage

Every press has a maximum rated capacity measured in tons. This limit must never be exceeded. Overloading the press can cause the frame to fracture or the hydraulic seals to blow out, resulting in an explosive release of energy and high-pressure fluid. If the press has a pressure gauge, know the maximum reading that corresponds to its tonnage limit.

Use Proper Press Plates and Blocks

Never use random pieces of scrap metal, sockets, or other makeshift items to bridge gaps or support a workpiece. Use only properly rated press plates and V-blocks designed to withstand compressive force without shattering. These tools help distribute the load evenly.

Keep Hands and Body Clear

This is the most fundamental rule. Once the ram begins to move, your hands and body must never be between the ram and the press bed. Use long-handled tools to make any final adjustments to the workpiece before applying pressure.

Understanding the Hidden Dangers

The most serious hydraulic press accidents often stem from a misunderstanding of the physics involved. Recognizing these hidden dangers is key to developing an expert safety mindset.

The Risk of Stored Energy

As you apply force, the workpiece and the steel frame of the press itself deform slightly, storing energy like a giant, compressed spring. If the workpiece suddenly fractures, this stored energy is released instantly and explosively, capable of sending shrapnel across a workshop at lethal speeds.

The Deception of Slow Movement

The slow, quiet, and seemingly controlled movement of the hydraulic ram can create a dangerous false sense of security. It's crucial to remember that even at a slow speed, the press is exerting immense, unforgiving force.

The Hazard of Brittle Materials

Be extremely cautious when pressing bearings, hardened steel, or other brittle components. These materials do not deform before failure; they shatter. This is a primary source of high-velocity projectile injuries. Enclosing the work area with a polycarbonate shield is highly recommended in these cases.

A Safety Mindset for Every Scenario

Your approach to safety should adapt to the task at hand. Use these guidelines to ensure you are applying the right level of caution.

- If your primary focus is routine workshop use: Make pre-operation checks and proper workpiece centering a non-negotiable habit for every single job.

- If your primary focus is training new operators: Emphasize the concept of stored energy and the risk of shrapnel, as this explains the critical "why" behind every other safety rule.

- If your primary focus is pressing unfamiliar or brittle objects: Begin with very low pressure, listen for any auditory cues like creaking or popping, and always use a safety shield, assuming the object will shatter.

Ultimately, true safety with a hydraulic press comes from a deep and constant respect for the immense forces you are controlling.

Summary Table:

| Safety Measure | Key Action | Purpose |

|---|---|---|

| Pre-Operation Check | Inspect frame, hoses, and safety guards | Prevent mechanical/hydraulic failure |

| Personal Protective Equipment (PPE) | Wear safety glasses, face shield, steel-toed boots | Protect against debris and impact |

| Workpiece Setup | Center load perfectly; avoid side-loading | Prevent machine damage and projectile ejection |

| Respect Load Capacity | Never exceed the press's rated tonnage | Avoid catastrophic frame or seal failure |

| Safe Operation | Keep hands/body clear; use proper press plates | Eliminate crush and shrapnel risks |

Ensure your lab's hydraulic press operations are safe and efficient. KINTEK specializes in high-quality lab equipment and consumables, providing reliable hydraulic presses and safety accessories designed for demanding laboratory environments. Our experts can help you select the right equipment and establish best practices to protect your team and your assets. Contact us today to discuss your specific laboratory needs and enhance your safety protocols.

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What is the role of a laboratory-grade heated hydraulic press in MEA fabrication? Optimize Fuel Cell Performance

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating