At its core, a retort furnace is a specialized piece of equipment used for high-temperature thermal processes that require precise control over the gaseous atmosphere surrounding the material. It is essential for treatments where interaction with air would be detrimental, such as various forms of metal heat treatment, sintering, and soldering, as well as for processing materials like glass and ceramics.

The defining feature of a retort furnace is not just its ability to generate heat, but its use of a sealed, gas-tight chamber—the "retort"—which allows operators to create a controlled environment, from a pure vacuum to one filled with inert or reactive gases. This control is the key to all of its applications.

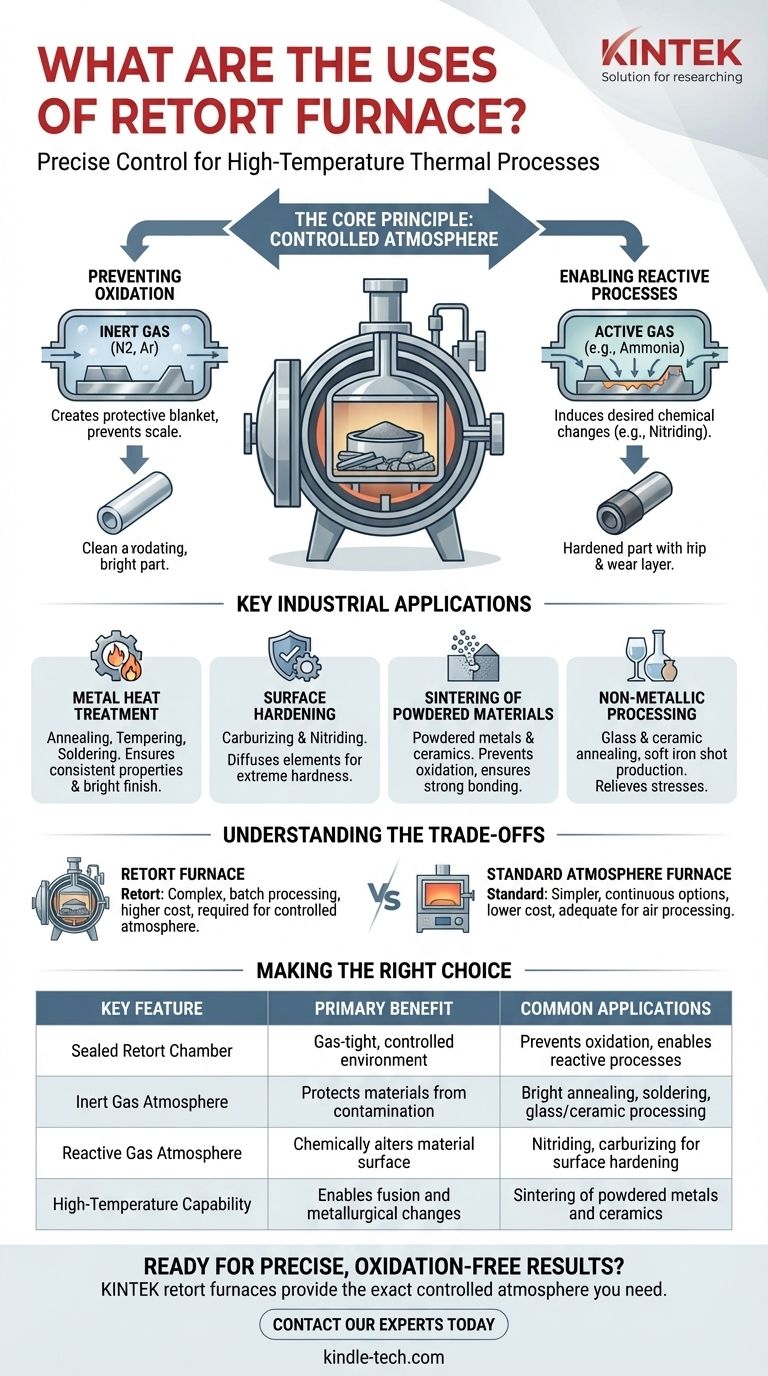

The Core Principle: A Controlled Atmosphere

The function of a retort furnace is fundamentally different from a standard oven or kiln that simply heats materials in ambient air. Its value comes from mastering the environment within the heating chamber.

What Is a "Retort"?

The "retort" is a metallic or ceramic vessel that is hermetically sealed. This vessel holds the parts being treated and is placed inside the main furnace body, which contains the heating elements (either electric or gas-fired).

This two-part design separates the heat source from the processing atmosphere, ensuring the material is only exposed to the specific gases you introduce.

Preventing Oxidation and Contamination

Many metals, when heated to high temperatures in the presence of oxygen, will oxidize, forming a layer of scale on the surface that can ruin the part's finish and dimensions.

A retort furnace solves this by first purging the chamber of air and then filling it with an inert gas, such as nitrogen or argon. This protective blanket prevents oxidation and ensures a bright, clean surface finish after treatment.

Enabling Reactive Processes

Beyond simply protecting a material, a retort furnace allows for processes that chemically alter a material's surface.

By introducing specific active gases into the sealed retort at high temperatures, you can induce desired chemical reactions. A prime example is nitriding, where ammonia gas is used to diffuse nitrogen into the surface of steel to create an extremely hard wear layer.

Key Industrial Applications

The ability to precisely control the atmosphere makes retort furnaces indispensable for a range of high-value industrial and laboratory tasks.

Metal Heat Treatment

This is the most common use. Processes like annealing, tempering, and soldering are performed in a retort furnace when surface finish and material purity are critical. The controlled atmosphere prevents discoloration and ensures consistent metallurgical properties.

Surface Hardening and Case Hardening

Processes like carburizing and nitriding rely entirely on the retort design. These methods require a carbon-rich or nitrogen-rich atmosphere to diffuse elements into the steel's surface, a feat that is impossible in an open-air furnace.

Sintering of Powdered Materials

Sintering involves heating compacted powders (like powdered metals or ceramics) to just below their melting point, causing the particles to fuse together. Performing this in a retort with a controlled atmosphere prevents the tiny particles from oxidizing, which would inhibit proper bonding and compromise the final part's strength.

Processing Non-Metallic Materials

Retort furnaces are also used for specialized applications involving other materials. This includes annealing glass or ceramic components to relieve internal stresses and producing materials like annealed soft iron shot for ammunition.

Understanding the Trade-offs

While powerful, a retort furnace is not always the necessary choice. Understanding its limitations is key to using it appropriately.

Retort Furnace vs. Standard Atmosphere Furnace

A standard atmosphere furnace is simpler and heats parts directly in the air. It is perfectly adequate for processes where surface oxidation is acceptable or even desired.

A retort furnace is chosen only when the process chemistry demands a controlled, non-oxidizing, or reactive environment.

Increased Complexity and Cost

The need for a sealed retort, vacuum-tight flanges, and sophisticated gas-handling systems makes a retort furnace more complex and expensive than a simple air furnace. Maintenance of the seals is also a critical operational factor.

Batch Processing Limitations

By their nature, most retort furnaces are designed for batch processing. Loading, sealing, purging, running the cycle, cooling, and unsealing takes time, which can be a limitation compared to some continuous furnace designs.

Making the Right Choice for Your Process

Selecting the right furnace technology comes down to the specific requirements of your material and the desired outcome.

- If your primary focus is simple heating, stress-relieving, or tempering in air: A standard, non-retort atmosphere furnace is likely more cost-effective and simpler to operate.

- If your primary focus is achieving a bright, clean finish and preventing any surface oxidation: A retort furnace with an inert gas atmosphere (nitrogen or argon) is necessary.

- If your primary focus is chemically altering a material's surface (like nitriding or carburizing): A retort furnace is the only tool capable of creating the required reactive gas environment.

Ultimately, you should choose a retort furnace when precise control over the process atmosphere is not just beneficial, but absolutely critical to the success of the outcome.

Summary Table:

| Key Feature | Primary Benefit | Common Applications |

|---|---|---|

| Sealed Retort Chamber | Creates a gas-tight, controlled environment | Prevents oxidation, enables reactive processes |

| Inert Gas Atmosphere (N2, Ar) | Protects materials from surface contamination | Bright annealing, soldering, glass/ceramic processing |

| Reactive Gas Atmosphere (e.g., Ammonia) | Chemically alters material surface | Nitriding, carburizing for surface hardening |

| High-Temperature Capability | Enables powder fusion and metallurgical changes | Sintering of powdered metals and ceramics |

Ready to achieve precise, oxidation-free results in your lab?

Whether your process requires bright annealing, sintering, or advanced surface hardening like nitriding, KINTEK's retort furnaces provide the exact controlled atmosphere you need. Our expertise in lab equipment ensures you get a reliable solution tailored for your specific materials and outcomes.

Contact our experts today to discuss how a KINTEK retort furnace can enhance your thermal processing capabilities.

Visual Guide

Related Products

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the function of a high-temperature atmosphere furnace in MOF/ZIF pyrolysis? Engineering Porous Carbon Supports

- What are the disadvantages of an inert gas system? Understanding the Safety and Operational Risks

- Why is Nitrogen gas used in Cu-Ag powder aging? Ensure Safety & Material Integrity in Your High-Temperature Process

- Why is argon better than nitrogen for inert atmosphere? Ensure Absolute Reactivity & Stability

- What is an exothermic atmosphere? A Guide to Cost-Effective, Self-Sustaining Heat Treatment Gases

- What is an atmosphere furnace? A Guide to Controlled Environment Heating

- Why is an atmosphere furnace required for LLZTO coatings on NCM523? Achieve Precise Oxide Control

- What is the significance of using high-purity argon in high-temperature furnaces? Ensure Coating Stability Test Accuracy