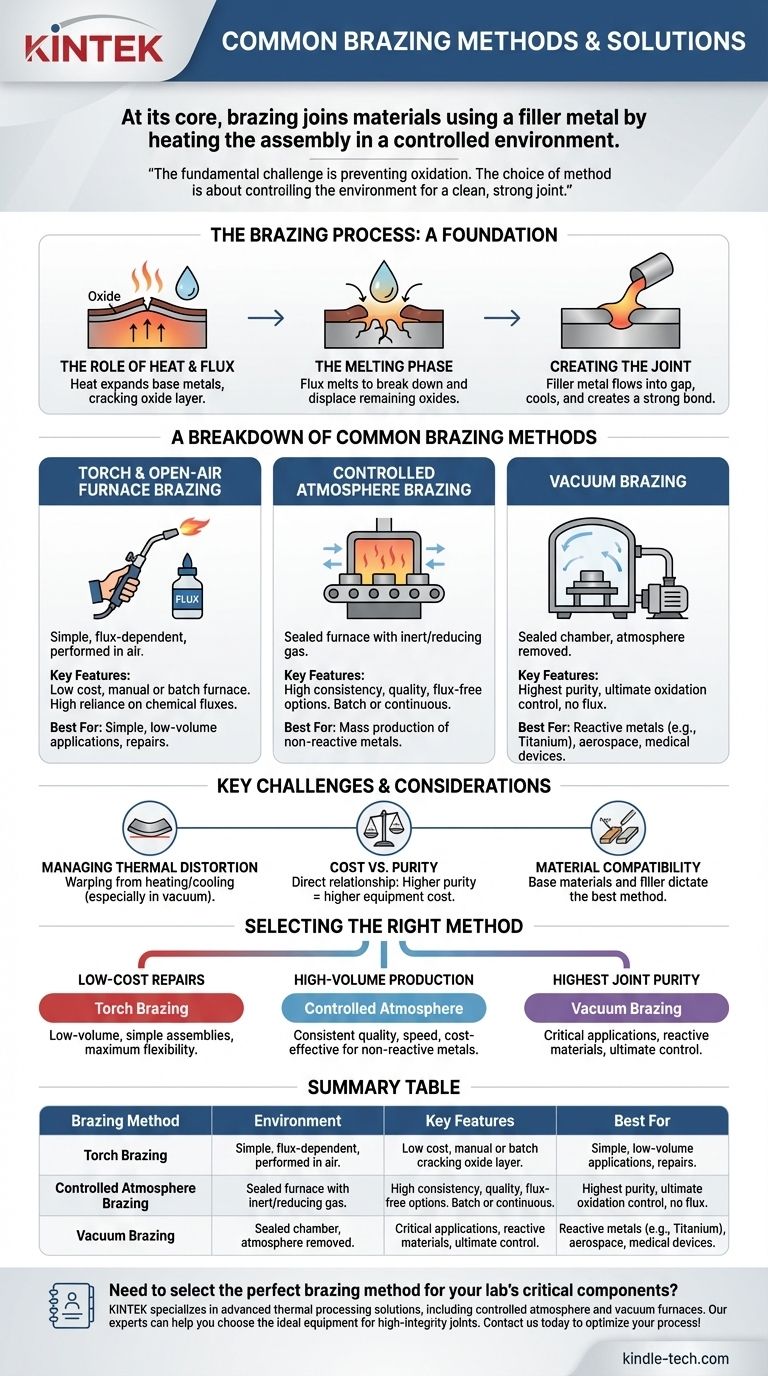

At its core, brazing joins materials using a filler metal by heating the assembly in a controlled environment. The most common brazing methods are differentiated by the type of environment, or atmosphere, they use to protect the joint during this heating process. These primarily include open-air furnace or torch brazing, controlled atmosphere brazing using inert gases, and vacuum brazing, which removes the atmosphere entirely.

The fundamental challenge in any brazing operation is preventing oxidation of the base metals at high temperatures. Therefore, the choice of a brazing method is ultimately a decision about how to best control the environment to ensure a clean, strong, and reliable joint.

The Brazing Process: A Foundation

Before comparing methods, it's crucial to understand the universal steps that occur when a brazed joint is formed, particularly with materials like aluminum that have a tough oxide layer.

The Role of Heat and Flux

The process begins by heating the assembly. As the temperature rises, the base metals expand. This differential expansion can cause the protective oxide layer on the surface to crack.

The Melting Phase

At a specific temperature, a chemical flux (if used) will melt and flow into these cracks. Its job is to chemically break down and displace the remaining oxides, preparing a clean surface for the filler metal.

Creating the Joint

Finally, as the temperature rises further, the filler metal melts. Pulled by capillary action, it flows into the tight gap between the clean base metals, cools, and solidifies to create a strong, permanent metallurgical bond.

A Breakdown of Common Brazing Methods

The environment in which this heating process occurs defines the brazing method. Each offers a different level of control over contamination, especially oxidation.

Torch and Open-Air Furnace Brazing

This is the most straightforward method, often performed manually with a torch or in a simple batch furnace open to the air. It is highly dependent on chemical fluxes to protect the joint area from atmospheric oxygen.

This method is best suited for simple, low-volume applications where the highest joint purity is not the primary concern.

Controlled Atmosphere Brazing

This advanced method takes place inside a sealed furnace filled with a specific gas. This controlled atmosphere is designed to be either inert (non-reactive) or actively reducing, preventing oxidation without relying solely on chemical flux.

Furnaces for this method can be batch types, like a retort furnace for hydrogen brazing, or continuous types, where parts move through the furnace on a conveyor belt for high-volume production. This approach offers excellent consistency and quality for large-scale manufacturing.

Vacuum Brazing

Vacuum brazing represents the highest level of environmental control. The parts are heated inside a sealed, cold-wall chamber from which nearly all air and other gases have been removed by a vacuum pump.

By eliminating the atmosphere, this method provides the ultimate protection against oxidation and contamination. It is essential for joining reactive metals like titanium or for applications in aerospace, medical devices, and high-performance electronics where joint integrity is absolutely critical.

Key Challenges and Considerations

While effective, brazing is a precise thermal process that comes with inherent challenges. The choice of method is often a trade-off between control, cost, and complexity.

Managing Thermal Distortion

Heating and cooling parts can cause them to warp or change shape. This is a significant concern in vacuum brazing, where measures like stress-relieving parts beforehand or using rigid fixtures are necessary to maintain dimensional accuracy.

Cost vs. Purity

There is a direct relationship between the cost of the equipment and the purity of the resulting joint. A simple torch setup is inexpensive, while a high-end vacuum furnace represents a significant capital investment.

Material and Filler Compatibility

The base materials and the chosen filler metal dictate the best brazing method. For example, joining stainless steel or advanced alloys often requires the clean environment of a vacuum furnace, while simpler copper or brass components may be well-suited for atmosphere brazing.

Selecting the Right Brazing Method

Your choice should be directly informed by the requirements of your materials, production volume, and the final application of the part.

- If your primary focus is low-cost repairs or simple, one-off assemblies: Torch brazing with an appropriate flux provides maximum flexibility and minimal equipment cost.

- If your primary focus is high-volume, consistent production of non-reactive metals: Controlled atmosphere brazing in a continuous furnace offers the best balance of quality, speed, and cost-per-part.

- If your primary focus is joining reactive materials or achieving the absolute highest joint purity for critical applications: Vacuum brazing is the only method that provides the necessary environmental control.

Understanding these distinct methods allows you to select the precise process that guarantees the integrity and performance of your final assembly.

Summary Table:

| Brazing Method | Environment / Atmosphere | Key Features | Best For |

|---|---|---|---|

| Torch / Open-Air | Air (Uses Chemical Flux) | Low cost, simple, manual | Low-volume, simple assemblies, repairs |

| Controlled Atmosphere | Inert/Reducing Gas (e.g., Hydrogen) | High consistency, flux-free, high-volume | Mass production of non-reactive metals |

| Vacuum | High Vacuum (No Atmosphere) | Highest purity, no flux, ultimate oxidation control | Reactive metals (e.g., titanium), aerospace, medical devices |

Need to select the perfect brazing method for your lab's critical components? The right process is essential for joint strength, purity, and production efficiency. KINTEK specializes in advanced thermal processing solutions, including lab furnaces for controlled atmosphere and vacuum brazing. Our experts can help you choose the ideal equipment to ensure reliable, high-integrity joints for your specific materials and applications. Contact us today to discuss your brazing requirements and optimize your process!

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- What gases are used in inert atmospheres? Choose the Right Gas for Non-Reactive Environments

- What is an inert atmosphere heat treatment? Protect Your Metals from Oxidation & Decarburization

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety