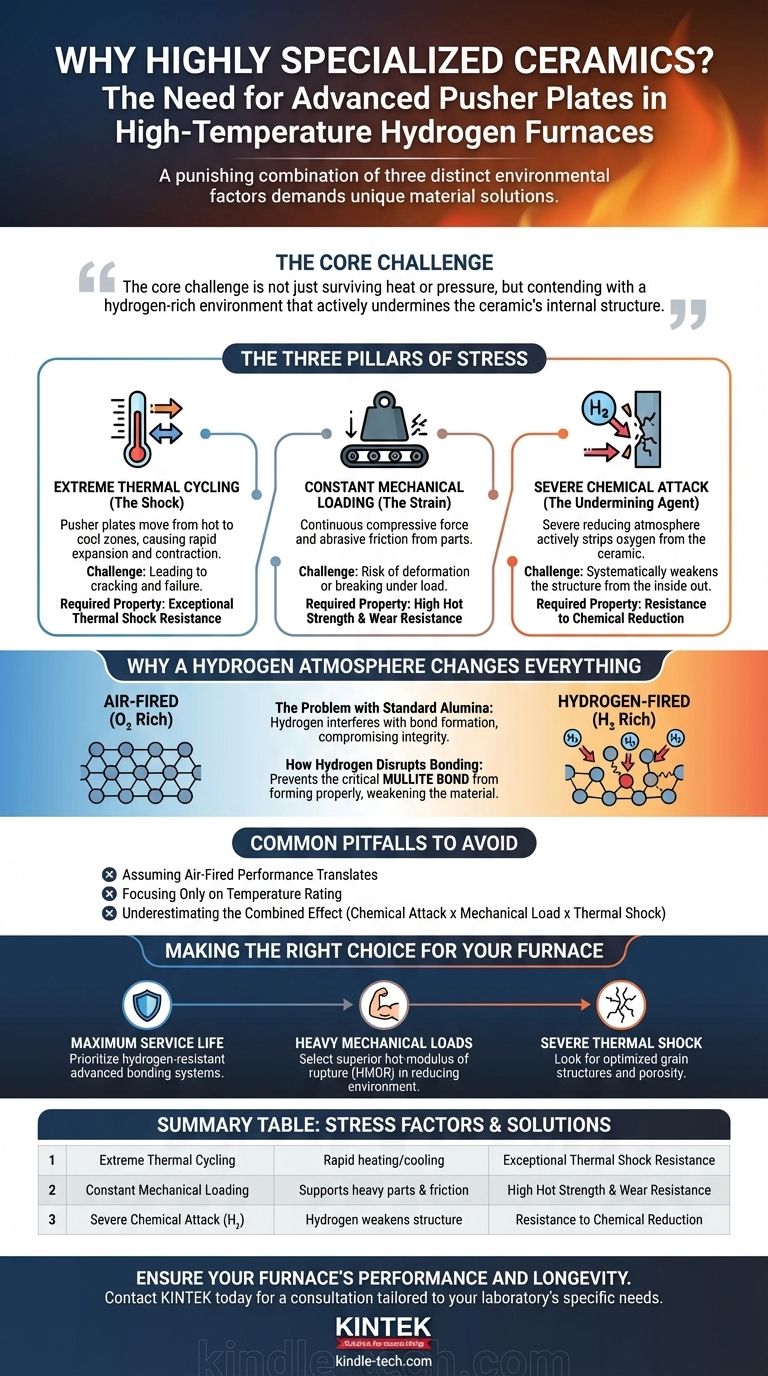

The need for highly specialized ceramics in high-temperature hydrogen furnaces stems from a punishing combination of three distinct environmental factors. These plates must simultaneously endure extreme thermal cycling, constant mechanical stress from conveying parts, and aggressive chemical attack from the severe reducing hydrogen atmosphere.

The core challenge is not just surviving heat or pressure, but contending with a hydrogen-rich environment that actively undermines the ceramic's internal structure, making it vulnerable to mechanical and thermal failure in ways that do not occur in standard air-fired furnaces.

The Three Pillars of Stress

To understand the need for specialized materials, we must analyze each stress factor and how it interacts with the others. A material that excels at handling one or two of these challenges will often fail when subjected to all three simultaneously.

Extreme Thermal Cycling (The Shock)

Pusher plates are in constant motion, moving from the extreme heat of the furnace's hot zone to the relatively cool quench zone. This rapid temperature change, or thermal cycling, induces immense internal stress.

The material rapidly expands and contracts, which can easily lead to cracking and catastrophic failure in standard ceramics. This demands a material with exceptional thermal shock resistance.

Constant Mechanical Loading (The Strain)

These plates serve as the conveyor system for heavy parts, subjecting them to continuous mechanical loading. This includes the compressive force from the weight of the parts and the abrasive friction from their movement.

The ceramic must possess high hot strength and wear resistance to avoid deforming, cracking, or breaking under this relentless physical strain at elevated temperatures.

Severe Chemical Attack (The Undermining Agent)

This is the most unique and destructive factor. High-temperature hydrogen is a severe reducing atmosphere, meaning it actively seeks to strip oxygen atoms from other compounds.

This chemical attack targets the oxide-based binders and grains within the ceramic itself. Over time, this systematically weakens the entire structure from the inside out, making it far more susceptible to failure from thermal and mechanical stresses.

Why a Hydrogen Atmosphere Changes Everything

The presence of hydrogen is the critical variable that renders many high-performance ceramics ineffective. Materials that perform perfectly well in air, even at higher temperatures, can fail disastrously in these specialized furnaces.

The Problem with Standard Alumina

High-purity alumina is a go-to material for many high-temperature applications due to its strength and stability in air. However, in a hydrogen atmosphere, it becomes vulnerable.

The hydrogen actively interferes with the chemical reactions that form strong bonds within the ceramic during its manufacturing and use, compromising its structural integrity.

How Hydrogen Disrupts Bonding

The primary challenge is creating a strong, well-formed mullite bond within the ceramic matrix. This bond is essential for providing the pusher plate with its required strength and resilience.

In a hydrogen atmosphere, the chemical environment prevents this critical bond from forming properly. The result is a fundamentally weaker material, regardless of the quality of the raw ingredients.

Common Pitfalls to Avoid

Selecting the right material requires understanding the unique failure modes present in a hydrogen environment. Overlooking the chemical aspect is the most common and costly mistake.

Assuming Air-Fired Performance Translates

Do not specify a material based solely on its performance data from air-fired applications. The chemical reactivity of hydrogen fundamentally alters how the ceramic behaves under heat and load.

Focusing Only on Temperature Rating

A high-temperature rating is necessary but not sufficient. A material's ability to resist chemical reduction and thermal shock is equally, if not more, important for ensuring a long service life.

Underestimating the Combined Effect

The danger lies in the synergistic effect of the three stress factors. The chemical attack weakens the material, which then cannot withstand the mechanical load, and a small crack from thermal shock rapidly grows into a complete failure.

Making the Right Choice for Your Furnace

Your material selection must be based on a holistic view of the operating environment, with special emphasis on mitigating the effects of the hydrogen atmosphere.

- If your primary focus is maximum service life: Prioritize materials specifically engineered for hydrogen atmospheres, which use advanced bonding systems that are resistant to chemical reduction.

- If your primary focus is handling heavy mechanical loads: Select a formulation with superior hot-modulus of rupture (HMOR) that has been tested and proven in a reducing environment.

- If your primary focus is resisting severe thermal shock: Look for ceramics with optimized grain structures and porosity designed to dissipate the stresses of rapid heating and cooling.

Ultimately, choosing the right pusher plate requires moving beyond standard datasheets and selecting a material scientifically designed to resist the combined assault of thermal, mechanical, and chemical degradation.

Summary Table:

| Stress Factor | Key Challenge | Required Material Property |

|---|---|---|

| Extreme Thermal Cycling | Rapid heating/cooling causes internal stress | Exceptional Thermal Shock Resistance |

| Constant Mechanical Loading | Supports heavy parts and abrasive friction | High Hot Strength & Wear Resistance |

| Severe Chemical Attack (H₂) | Hydrogen strips oxygen, weakening the structure | Resistance to Chemical Reduction |

Ensure your furnace's performance and longevity. The punishing environment of a high-temperature hydrogen furnace demands pusher plates engineered to withstand the unique combination of thermal, mechanical, and chemical stresses. KINTEK specializes in high-performance lab equipment and consumables, including ceramics specifically formulated for severe reducing atmospheres.

Let our experts help you select the right material to avoid costly failures and maximize service life. Contact KINTEK today for a consultation tailored to your laboratory's specific needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does the degradation of a thermocouple affect temperature measurement? Prevent Silent Drift & Ensure Process Accuracy

- Why are zirconia grinding balls preferred for LLZTO milling? Ensure Material Purity & High Ionic Conductivity

- What is the mechanism of Rotavapor? Efficient Solvent Removal at Low Temperatures Explained

- Why is Boron Nitride or graphite paper used in hot-press sintering? Ensure Smooth Demolding & Protect Your Molds

- Why are zirconia grinding jars selected for Li7P3S11 solid-state electrolytes? Ensure Purity in Sulfide Synthesis

- What is the function of a PID temperature control system? Ensure Stability in Nuclear Simulations

- Why are high-temperature packing seals used instead of standard silicone O-rings? Ensure Safety and Integrity

- What is the function of a laboratory magnetic stirrer? Enhance Yield & Uniformity in Thermal Extraction