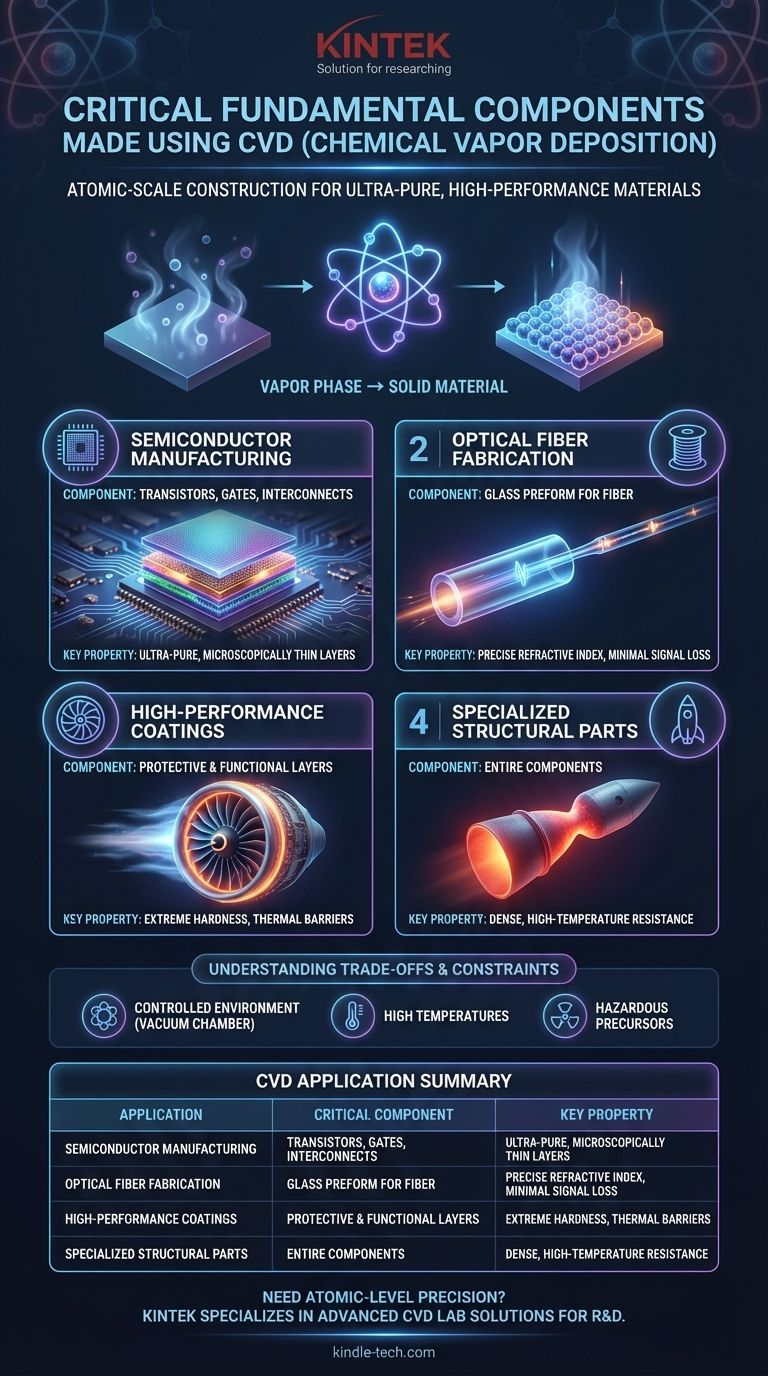

At its core, Chemical Vapor Deposition (CVD) is the foundational process used to manufacture the ultra-pure, high-performance thin films that form the heart of modern electronics and communications. Its most critical applications are in creating the intricate layers of a semiconductor chip and producing the core material for optical fibers, components that are fundamental to our digital world.

The true significance of CVD is not just as a coating technique, but as a method of atomic-scale construction. It allows engineers to build materials from gaseous precursors, creating components with a level of purity, precision, and performance that conventional fabrication methods cannot achieve.

The Role of CVD: From Surface Protection to Core Function

Chemical Vapor Deposition is a process where a solid material is formed on a heated surface (substrate) from a chemical reaction in the vapor or gas phase. This "bottom-up" approach of building materials atom by atom is what makes it so powerful.

Creating the Foundation of Electronics

The most critical use of CVD is in semiconductor manufacturing. Every integrated circuit, from the processor in your computer to the memory in your phone, is built using this process.

CVD is used to deposit multiple, microscopically thin layers of different materials—including silicon, dielectrics, and conductive metals—onto a silicon wafer. These layers form the transistors, gates, and interconnects that make up the chip's circuitry.

Enabling Global Communications

CVD is essential for fabricating optical fibers. The process is used to create a large glass cylinder called a "preform," which has a precisely controlled refractive index.

This preform is then heated and drawn into the hair-thin fiber that transmits data as light pulses over vast distances. The ultra-high purity achieved by CVD is what minimizes signal loss, enabling high-speed global communication networks.

Engineering High-Performance Coatings

Beyond creating the core of a component, CVD is widely used to apply protective and functional coatings that dramatically enhance the performance of a part.

These coatings can provide extreme hardness for cutting tools, thermal barriers for jet engine turbine blades, and biocompatibility for medical implants. The deposited film becomes an integral part of the component's surface.

Building Specialized Structural Parts

In certain high-value applications, CVD is used to create the entire component, not just a layer on its surface. This is particularly useful for parts that must withstand extreme conditions.

Examples include dense, thin-walled components like rocket nozzles or specialized crucibles that are difficult or impossible to make using traditional machining or casting.

Understanding the Trade-offs

While incredibly powerful, CVD is not a universal solution. Its application is dictated by a specific set of requirements and constraints that make it ideal for high-performance, high-value components.

The Need for a Controlled Environment

The entire CVD process must occur within a reaction chamber, often under vacuum. This requires sophisticated and expensive equipment to precisely control temperature, pressure, and the flow of reactant gases.

Limitations of High Temperature

Most CVD processes operate at very high temperatures. This heat is necessary to drive the chemical reactions but limits the types of materials that can be used as substrates, as they must be able to withstand the thermal stress without deforming or melting.

The Challenge of Precursor Chemicals

The success of CVD depends on the availability of volatile precursor gases that contain the desired atoms. These gases are often highly reactive, toxic, or corrosive, demanding complex safety and handling protocols.

Making the Right Choice for Your Goal

The decision to use CVD is driven entirely by the need for material properties that cannot be achieved through other means.

- If your primary focus is microelectronics: CVD is the non-negotiable, fundamental process for building the layered structures of integrated circuits.

- If your primary focus is high-speed data transmission: CVD is the only method that can produce the ultra-pure glass preforms required for low-loss optical fiber.

- If your primary focus is component survival in extreme environments: CVD provides the high-performance thermal and wear-resistant coatings essential for aerospace and industrial applications.

Ultimately, Chemical Vapor Deposition is the enabling technology that allows us to engineer materials with the atomic-level precision required for today's most critical components.

Summary Table:

| CVD Application | Critical Component Created | Key Property Achieved |

|---|---|---|

| Semiconductor Manufacturing | Transistors, Gates, Interconnects | Ultra-pure, microscopically thin layers |

| Optical Fiber Fabrication | Glass Preform for Fiber | Precise refractive index, minimal signal loss |

| High-Performance Coatings | Protective Layers (e.g., for turbine blades) | Extreme hardness, thermal barriers |

| Specialized Structural Parts | Entire Components (e.g., rocket nozzles) | Dense, high-temperature resistance |

Need to engineer materials with atomic-level precision? KINTEK specializes in providing the advanced lab equipment and consumables required for cutting-edge Chemical Vapor Deposition (CVD) processes. Whether your focus is on semiconductor R&D, developing new optical materials, or creating durable coatings, our solutions help you achieve the ultra-pure, high-performance results essential for modern technology. Contact our experts today to discuss how we can support your laboratory's specific CVD needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application