At its core, an industrial freeze dryer is distinguished from other types by its massive scale and design for high-volume, continuous manufacturing. While smaller units focus on research or process development, industrial systems are purpose-built to function as the workhorses of a full-scale production line, handling capacities measured in hundreds of liters and processing thousands of units per cycle.

The critical distinction is not merely size, but intent. Industrial freeze dryers are engineered for maximum throughput, repeatability, and automation, whereas laboratory and pilot models are designed for flexibility, data collection, and process refinement.

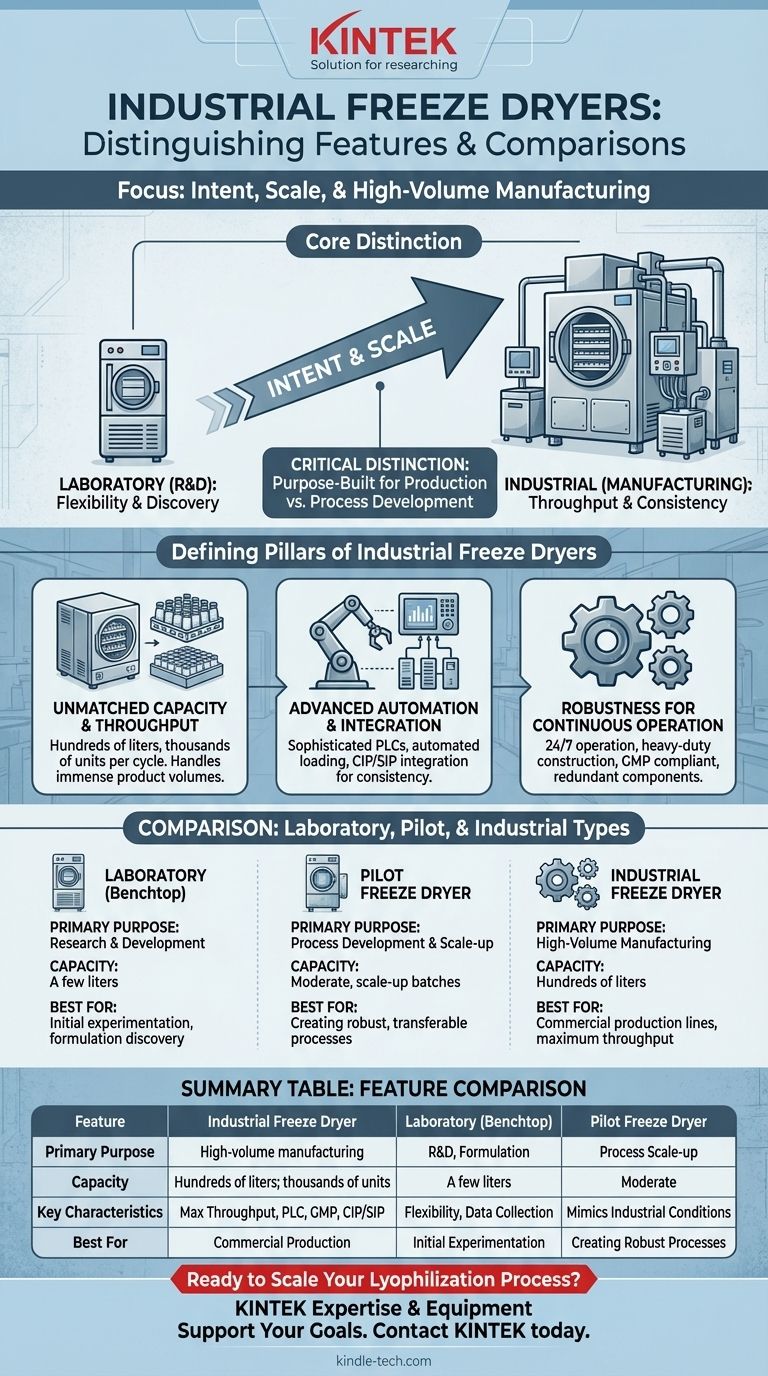

The Defining Pillars of an Industrial Freeze Dryer

An industrial freeze dryer's design philosophy centers on integrating seamlessly into a large-scale manufacturing environment. This leads to several key characteristics that set it apart.

Unmatched Capacity and Throughput

Industrial units are defined by their ability to handle immense product volumes. This isn't just about the chamber size, but the entire system's capacity to remove vast quantities of water vapor quickly.

Their capacities often range from tens to hundreds of liters of ice-condensing capability per cycle. This translates to processing thousands of vials or many square meters of bulk product trays at once.

Advanced Automation and Integration

These systems are rarely standalone machines. They feature sophisticated Programmable Logic Controllers (PLCs) that manage every phase of the drying cycle with extreme precision, ensuring batch-to-batch consistency.

They are also designed for integration with automated loading/unloading systems, Clean-in-Place (CIP), and Sterilize-in-Place (SIP) systems, which are essential for pharmaceutical and regulated food production.

Robustness for Continuous Operation

An industrial freeze dryer is built for the rigors of 24/7 operation. This means heavy-duty construction, redundant critical components (like refrigeration compressors and vacuum pumps), and materials that comply with strict regulatory standards like Good Manufacturing Practices (GMP).

How They Compare to Other Freeze Dryer Types

Understanding the industrial model becomes clearer when contrasted with its smaller counterparts, each of which serves a distinct purpose in the product lifecycle.

Laboratory (Benchtop) Freeze Dryers

These are the smallest units, designed for research and development (R&D). Their main goal is flexibility, allowing scientists to test many different formulations and cycle parameters on a small scale. Capacity is minimal, often just a few liters.

Pilot Freeze Dryers

Pilot units are the crucial bridge between the lab and the factory floor. They are used for process development and scale-up, allowing engineers to refine a drying cycle on a moderately sized batch that mimics the conditions of an industrial machine. They are also used for producing material for clinical trials or niche markets.

Understanding the Trade-offs: Cost vs. Capability

The significant leap in capability from a pilot to an industrial freeze dryer comes with fundamental trade-offs that go far beyond the initial purchase price.

The Investment in Scale

Industrial freeze dryers are the most expensive option by a significant margin. This cost reflects not only the size but also the complex automation, validation documentation packages (IQ/OQ/PQ), and compliance with stringent industry regulations.

Operational Footprint and Complexity

These machines demand substantial facility infrastructure, including high-capacity electrical service, cooling water, and often steam generation. They require skilled, dedicated operators and a rigorous preventative maintenance schedule to ensure uptime and reliability.

The Inefficiency of Mismatching

Using an industrial dryer for early-stage development is highly inefficient. The cost per cycle, lengthy setup time, and large amount of product required make it prohibitive for experimental work. Conversely, attempting production on a pilot unit creates a severe bottleneck, preventing any meaningful commercial output.

Making the Right Choice for Your Goal

Selecting the correct type of freeze dryer is entirely dependent on your specific objective within the product lifecycle.

- If your primary focus is research and development: A flexible laboratory freeze dryer is the ideal tool for formulation discovery and initial experimentation.

- If your primary focus is process optimization and scale-up: A pilot freeze dryer provides the necessary environment to create a robust, repeatable, and transferable drying cycle.

- If your primary focus is high-volume, commercial manufacturing: An industrial freeze dryer is the only solution built for the demands of continuous production and maximum throughput.

Ultimately, choosing the right freeze dryer is about aligning the equipment's core purpose with your operational mission.

Summary Table:

| Feature | Industrial Freeze Dryer | Laboratory (Benchtop) | Pilot Freeze Dryer |

|---|---|---|---|

| Primary Purpose | High-volume, continuous manufacturing | Research & Development (R&D) | Process development & scale-up |

| Capacity | Hundreds of liters; thousands of units | A few liters | Moderate, for scale-up batches |

| Key Characteristics | Maximum throughput, automation (PLC), GMP compliance, CIP/SIP systems | Flexibility, data collection | Mimics industrial conditions for cycle refinement |

| Best For | Commercial production lines | Initial experimentation and formulation discovery | Creating robust, transferable processes |

Ready to Scale Your Lyophilization Process?

Choosing the right equipment is critical to your success. Whether you are scaling up from R&D or need a reliable partner for your production line, KINTEK has the expertise and equipment to support your goals.

As a specialist in lab equipment and consumables, we understand the entire product lifecycle. We can help you select the ideal freeze dryer for your specific needs, ensuring efficiency, compliance, and maximum throughput.

Contact KINTEK today to discuss your project and discover how our solutions can enhance your laboratory's capabilities and drive your production forward.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

People Also Ask

- Why does the manufacturer affect the price of a lab freeze dryer? Invest in Reliability, Innovation & Support

- What factors should be considered when choosing a freeze dryer? Align Performance with Your Lab's Needs

- Why are conventional preservation methods less suitable for biological products? The Critical Risk to Efficacy and Safety

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- What are the main advantages of laboratory freeze drying? Preserve Sensitive Materials with Gentle Lyophilization