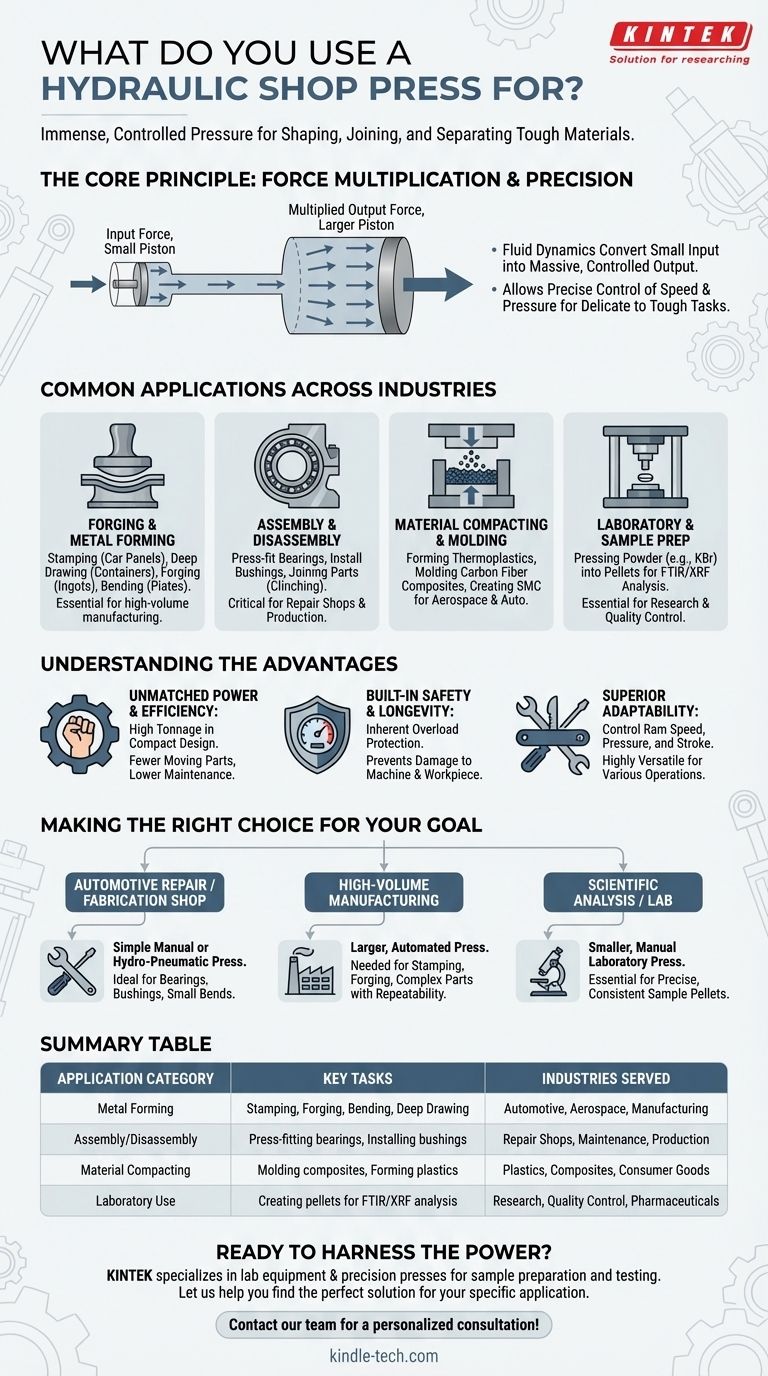

At its core, a hydraulic shop press is used to apply immense, controlled pressure. This force is leveraged for a wide range of tasks, primarily involving shaping, joining, or separating tough materials. Its applications span from automotive repair and metal fabrication to high-tech manufacturing and scientific sample preparation.

A hydraulic press is not just a tool for crushing things; it is a precision instrument for force multiplication. It uses the principle of fluid dynamics to convert a small input force into a massive, controllable output, making it indispensable for tasks that are impossible to perform by manual or mechanical means.

The Core Principle: How a Hydraulic Press Achieves Immense Force

Understanding Force Multiplication

A hydraulic press operates on Pascal's principle. A force applied to a small piston in a sealed system of incompressible fluid (like oil) creates pressure. This pressure is transmitted equally throughout the fluid, acting on a much larger piston.

Because the second piston has a larger surface area, the transmitted pressure results in a massively multiplied output force. This simple yet powerful concept allows a small motor or hand pump to generate many tons of force.

Precision and Control

Unlike purely mechanical presses, hydraulic systems allow for precise control over the ram's speed and the amount of pressure applied. This control is critical for complex forming operations and for safely pressing delicate components without causing damage.

Common Applications Across Industries

Forging and Metal Forming

The most common industrial use for a hydraulic press is shaping metal. Its immense, sustained pressure is ideal for these tasks.

Applications include stamping flat sheets into car body panels, deep drawing to create seamless containers, forging heated metal ingots into parts, and bending thick plates.

Assembly and Disassembly

In repair shops and manufacturing, presses are essential for assembly. They are used to press-fit bearings into housings, install bushings, and join parts together with a process called clinching.

Conversely, they are also the primary tool for disassembling these same interference-fit components without damaging them.

Material Compacting and Molding

Hydraulic presses are used to compact powders into solid forms or mold various materials under heat and pressure.

This includes forming thermoplastics, molding carbon fiber composites for aerospace and automotive parts, and creating sheet molded composites (SMC) for a variety of products.

Laboratory and Sample Preparation

In scientific settings, a hydraulic press provides the controlled force needed to prepare samples for analysis.

It is commonly used to press a powdered material, like potassium bromide (KBr), into a thin, transparent pellet for FTIR spectroscopy, or to create homogenous sample pellets for XRF analysis.

Understanding the Advantages

Unmatched Power and Efficiency

The primary advantage is the ability to generate extremely high tonnage in a relatively compact machine. The design is simple, with fewer moving parts than a mechanical press, leading to lower maintenance and production costs.

Built-in Safety and Longevity

Hydraulic systems have inherent overload protection. If the force limit is reached, a pressure relief valve opens, preventing damage to the machine or the workpiece. This also contributes to a longer lifespan for the press and its tooling.

Superior Adaptability

A single hydraulic press can be adapted for a wide variety of operations. The ability to control ram speed, pressure, and stroke length makes it far more versatile than a mechanical press, which typically has a fixed stroke.

Making the Right Choice for Your Goal

The specific application dictates the type and size of the press required.

- If your primary focus is automotive repair or a fabrication shop: A simple manual or hydro-pneumatic press is ideal for pressing bearings, bushings, and performing smaller bending jobs.

- If your primary focus is high-volume manufacturing: You will need a larger, automated press for stamping, deep drawing, forging, or molding complex parts with speed and repeatability.

- If your primary focus is scientific analysis: A smaller, manual laboratory press with precise pressure gauges is essential for creating consistent, high-quality sample pellets.

Ultimately, the hydraulic press is a foundational tool that leverages fluid power to masterfully shape and control the strongest materials.

Summary Table:

| Application Category | Key Tasks | Industries Served |

|---|---|---|

| Metal Forming | Stamping, Forging, Bending, Deep Drawing | Automotive, Aerospace, Manufacturing |

| Assembly/Disassembly | Press-fitting bearings, Installing bushings | Repair Shops, Maintenance, Production |

| Material Compacting | Molding composites, Forming plastics | Plastics, Composites, Consumer Goods |

| Laboratory Use | Creating pellets for FTIR/XRF analysis | Research, Quality Control, Pharmaceuticals |

Ready to Harness the Power of a Hydraulic Press?

Whether you're in a busy automotive shop, a high-volume manufacturing plant, or a precise research laboratory, the right press is key to your success. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision hydraulic presses ideal for sample preparation and material testing.

Let us help you find the perfect press for your specific application. Our experts can guide you to a solution that delivers the precise control and power you need.

Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How are laboratory hydraulic presses and powder pellet dies utilized in the assembly of all-solid-state batteries?

- What is role of KBr in IR-spectroscopy? Create Transparent Pellets for Accurate Solid Sample Analysis

- What can KBr be used as? The Essential Matrix for Accurate FTIR Spectroscopy

- What is the significance of applying 200 MPa of pressure with a laboratory hydraulic pellet press for composite ceramics?

- What are KBr pellets used for? A Key to Accurate FTIR Spectroscopy Analysis

- What happens when a hydraulic system overheats? Prevent Costly Damage and Downtime

- What role does a laboratory uniaxial hydraulic press play in LATP green body preparation? Essential Forming Guide

- What is the process for making pressed pellets for XRF analysis? Achieve Precision with High-Quality Sample Prep