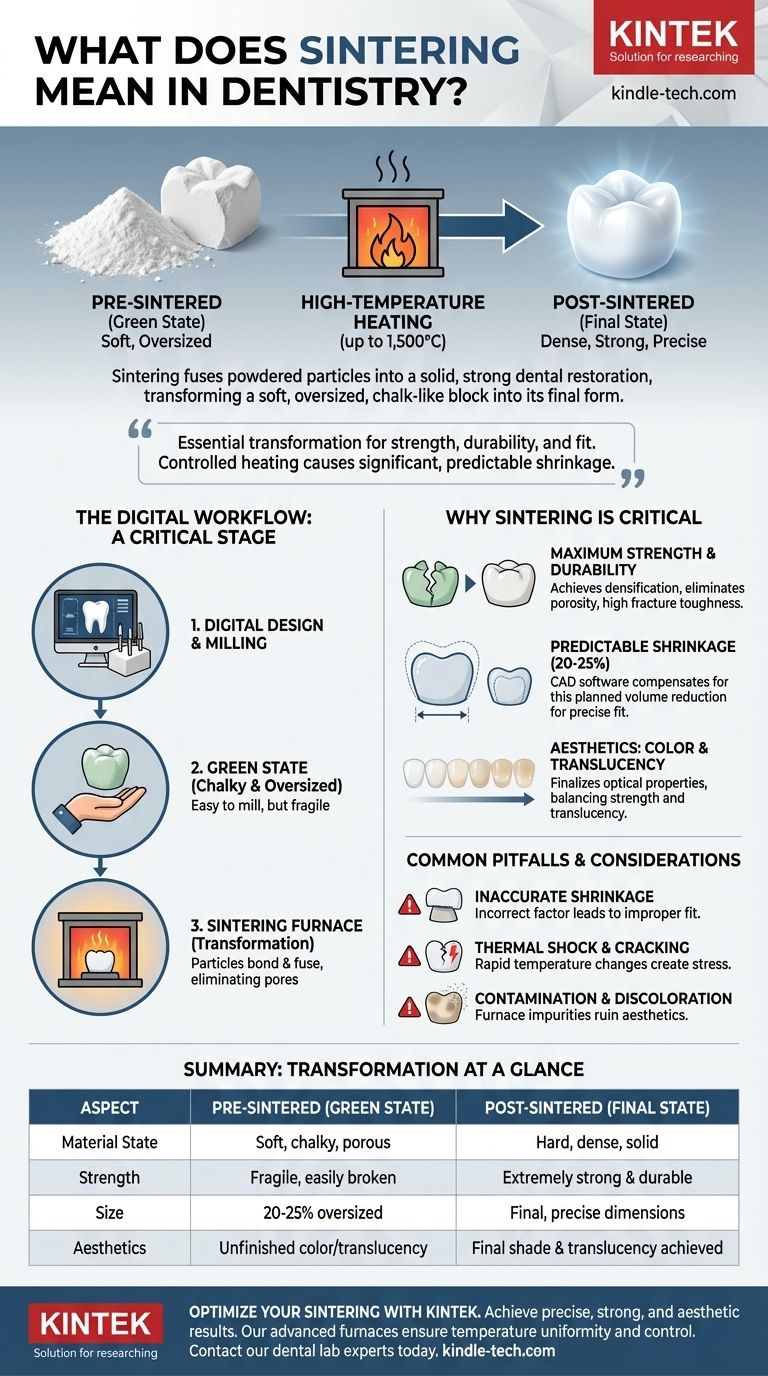

In dentistry, sintering is a high-temperature heating process that fuses powdered particles of a material, like zirconia or metal, into a solid, dense, and strong final restoration. This crucial step transforms a soft, oversized, and chalk-like milled block into its final, precisely fitting form, ready for clinical use.

Sintering is the essential transformation that gives modern dental restorations their required strength, durability, and fit. It is a process of controlled heating that causes significant, but predictable, shrinkage which must be accounted for in the initial digital design.

The Role of Sintering in the Digital Workflow

Sintering is not an isolated event; it's a critical stage in the modern CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) process for creating indirect restorations like crowns, bridges, and implant abutments.

From Digital Design to Milled Blank

The process begins with a digital scan of the patient's teeth. A technician then designs the restoration (e.g., a crown) in CAD software.

This digital file is sent to a milling machine, which carves the restoration out of a block of material, most commonly zirconia.

The "Green State": Milling a Chalky Material

The material block used for milling is not in its final, hard state. It is in a pre-sintered or "green state," which is soft and chalky.

This softness makes the material easy and fast to mill, reducing wear on the milling burs and shortening the production time. However, in this state, the restoration is fragile and much larger than its final intended size.

The Furnace: Transformation Through Heat

After milling, the oversized, chalky restoration is placed into a specialized high-temperature sintering furnace. The furnace follows a precise heating and cooling cycle, often lasting several hours.

During this cycle, the temperature reaches upwards of 1,500°C (2,732°F). This extreme heat causes the individual particles of the material to bond and fuse together, eliminating the pores between them.

Why Sintering is a Critical Transformation

The changes that occur during sintering are dramatic and essential for the clinical success of the restoration. Without this step, materials like zirconia would be completely unsuitable for use in the mouth.

Achieving Maximum Strength and Durability

The primary purpose of sintering is to achieve densification. By fusing the particles, the process creates a solid, non-porous structure with exceptional flexural strength and fracture toughness.

A pre-sintered zirconia crown can be easily broken by hand. After sintering, it becomes one of the strongest and most durable materials available in dentistry.

The Science of Predictable Shrinkage

As the pores between particles are eliminated, the material undergoes significant volumetric shrinkage, typically between 20% and 25%.

This is not a flaw but a planned feature of the process. The CAD software automatically compensates for this by designing a restoration that is 20-25% larger than the final desired dimensions. The precision of this calculation is critical for the final fit.

Finalizing Aesthetics: Color and Translucency

Sintering also finalizes the optical properties of the restoration. The process develops the material's final shade, chroma, and translucency.

Different sintering temperatures and cycle times can be used to alter the aesthetic outcome, allowing labs to balance properties like strength and translucency for different clinical needs (e.g., a strong posterior crown vs. a highly aesthetic anterior crown).

Common Pitfalls and Considerations

While essential, the sintering process must be perfectly controlled. Errors at this stage can ruin the restoration and lead to clinical failure.

The Challenge of Inaccurate Shrinkage

If the shrinkage factor for a specific batch of material is incorrect or the software calculation is off, the final restoration will not fit. It may be too small, too large, or warped, requiring a complete remake.

The Risk of Thermal Shock and Cracking

The heating and cooling rates during the sintering cycle are critical. If the temperature changes too rapidly, it can create internal stresses within the material, leading to micro-cracks or even complete fracture. This is known as thermal shock.

Contamination and Discoloration

Sintering furnaces must be kept meticulously clean. Any contaminants inside the furnace chamber, such as dust or residue from other materials, can become embedded in the restoration during heating, causing significant discoloration and compromising the aesthetics.

Making the Right Choice for Your Goal

Understanding the fundamentals of sintering helps clinicians and technicians troubleshoot issues and optimize outcomes based on clinical demands.

- If your primary focus is maximum strength (e.g., for a posterior bridge): Sintering cycles are often longer and at specific temperatures designed to produce the densest, most opaque, and strongest final result.

- If your primary focus is high aesthetics (e.g., for an anterior crown): Technicians may use lower sintering temperatures or specialized cycles designed to preserve the material's translucency, sometimes at a slight trade-off in maximum strength.

- If your primary focus is efficiency (e.g., for a single-day restoration): "Speed sintering" furnaces and compatible materials are available that dramatically shorten the cycle time, though this must be done carefully to avoid compromising the material's integrity.

Mastering the principles of sintering is fundamental to leveraging the full potential of modern digital dentistry for predictable, strong, and beautiful results.

Summary Table:

| Aspect | Pre-Sintered (Green State) | Post-Sintered (Final State) |

|---|---|---|

| Material State | Soft, chalky, porous | Hard, dense, solid |

| Strength | Fragile, easily broken | Extremely strong and durable |

| Size | 20-25% oversized | Final, precise dimensions |

| Aesthetics | Unfinished color/translucency | Final shade and translucency achieved |

Achieve precise, strong, and aesthetic dental restorations with every sintering cycle.

At KINTEK, we understand that the sintering furnace is the heart of your dental lab's production. Our advanced sintering furnaces are engineered for exceptional temperature uniformity and precise cycle control, ensuring your zirconia crowns and bridges achieve maximum density, strength, and accurate shrinkage every time.

Whether you focus on high-strength multi-unit bridges or highly aesthetic anterior crowns, KINTEK provides reliable equipment tailored to the needs of modern dental laboratories.

Ready to optimize your sintering process and elevate your restoration quality? Contact our dental lab equipment experts today to find the perfect sintering solution for your workflow.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary function of a Dental Press Furnace? Fabricate Strong, Aesthetic Dental Restorations

- What is a dental furnace? The Precision Oven for Creating Strong, Lifelike Dental Restorations

- In what contexts is a slow cooling protocol important for dental restorations? Ensure Durability with Precise Thermal Care

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- Why is regular calibration of electronic controllers necessary for sintering furnaces? Prevent Costly Temperature Errors

- What is the temperature of a dental furnace? Mastering Heat for Perfect Zirconia Sintering

- What are some common features of modern Dental Press Furnaces? Boost Lab Efficiency with Smart Technology

- What types of materials can a Dental Press Furnace process? Versatile Solutions for High-Performance Ceramics