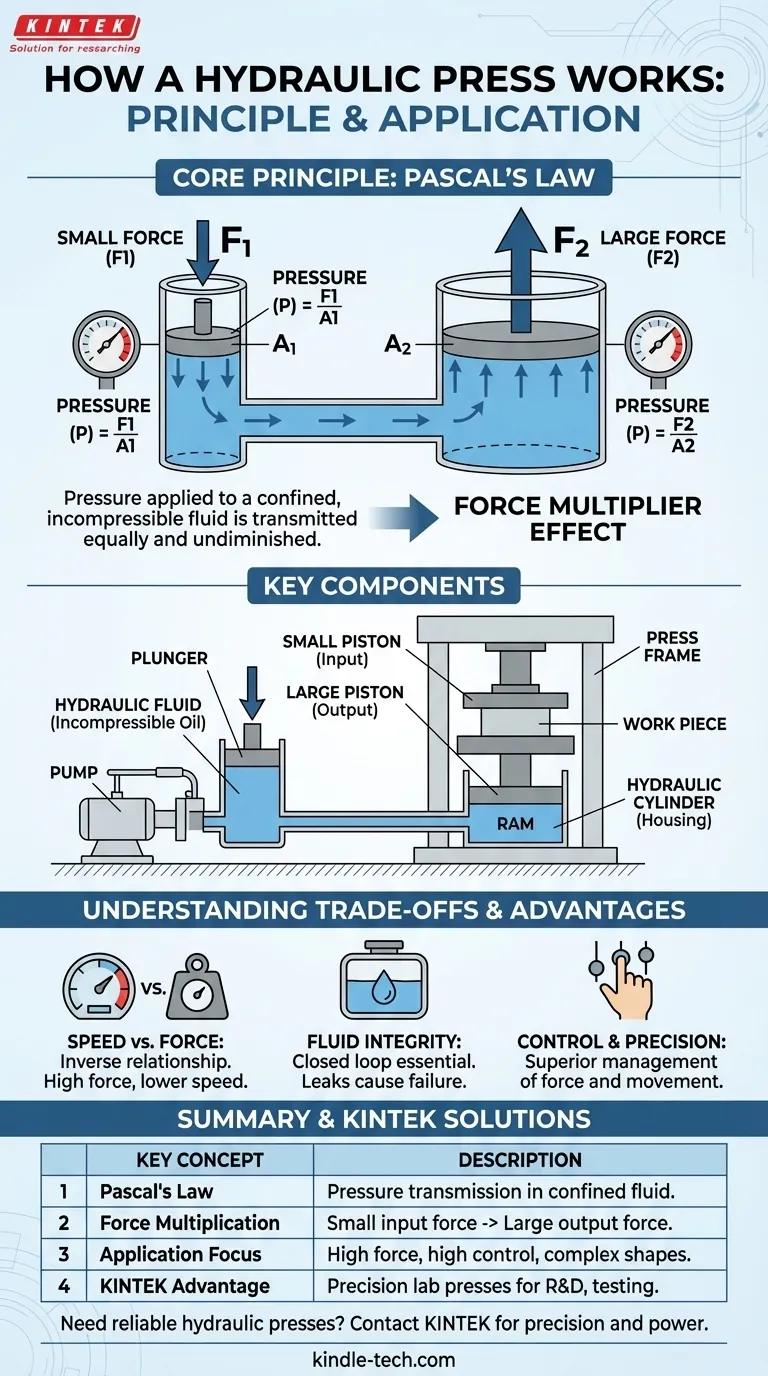

The working principle of a hydraulic press depends entirely on Pascal's Law. This fundamental principle of fluid mechanics states that when pressure is applied to a confined, incompressible fluid, that pressure is transmitted equally and undiminished to all parts of the fluid and the walls of its container. This allows the machine to act as a powerful force multiplier, transforming a small input force into a massive output force.

A hydraulic press is fundamentally a force multiplier. It leverages the properties of a confined fluid to convert a minimal force applied to a small area into an immense force exerted by a much larger area, enabling tasks that would otherwise be impossible.

The Core Principle: Pascal's Law Explained

To understand how a hydraulic press generates such tremendous force, we must first understand the relationship between force, pressure, and area. The system's power is derived not from magic, but from manipulating these variables within a closed hydraulic circuit.

A Contained and Incompressible Fluid

A hydraulic press relies on a fluid, typically a specialized oil, that is sealed within a system of cylinders and pipes. The critical property of this fluid is its incompressibility, meaning its volume does not significantly decrease under pressure.

Pressure is Transmitted Equally

According to Pascal's Law, any pressure applied to this fluid is instantly distributed throughout the entire system. If you apply 100 PSI (pounds per square inch) to one part of the system, that same 100 PSI of pressure is exerted on every other square inch of the system's interior surface.

The Force Multiplier Effect

This is where the true power of the system is unlocked. The system uses two pistons of different sizes: a small input piston (plunger) and a large output piston (ram).

Since Pressure = Force / Area, and the pressure is constant throughout the fluid, the force exerted by each piston is directly proportional to its surface area. By applying a small force to the small piston, you generate a specific pressure. This same pressure then acts on the much larger surface area of the output piston, resulting in a proportionally larger output force.

Key Components of the System

While the principle is simple, a few core components work together to make it a reality. These parts form the closed loop that contains and directs the hydraulic fluid.

The Small Piston (Plunger)

This is the input side of the system. An external force (from a pump or lever) pushes on this small piston, creating the initial pressure in the hydraulic fluid.

The Large Piston (Ram)

This is the output side that performs the work. The pressure from the fluid acts on the large surface area of this piston, driving it with immense force to press, crush, or form a material.

The Hydraulic Fluid

This is the medium used to transfer energy. Hydraulic oil is commonly used for its incompressibility, lubricating properties, and stability at high temperatures.

The Hydraulic Cylinder

This is the housing that contains the pistons and fluid. It must be strong enough to withstand the high internal pressures generated during operation.

Understanding the Trade-offs

The force multiplication of a hydraulic press does not come without compromises. Understanding these limitations is critical for its proper application.

Speed vs. Force

There is an inverse relationship between force and speed. To move the large piston a short distance, the small piston must travel a much greater distance. This makes hydraulic presses exceptionally powerful but often slower than their mechanical counterparts.

Fluid Integrity is Critical

The entire system depends on being a sealed, closed loop. Any leaks will cause a loss of pressure, leading to a catastrophic loss of force and system failure. The fluid must also be kept clean to prevent damage to seals and components.

Control and Precision

While they can be slower, hydraulic systems offer unparalleled control over force and speed. Operators can precisely manage the ram's movement, making them ideal for delicate or complex forging and molding operations where pressure must be applied gradually.

How to Apply This to Your Goal

Choosing a press technology depends entirely on the specific requirements of the job. The principles of the hydraulic press make it uniquely suited for certain tasks.

- If your primary focus is generating immense force with high control: A hydraulic press is the superior choice, as its force is consistent and easily regulated throughout the entire stroke.

- If your primary focus is high-speed, repetitive stamping: A mechanical press is often a better fit, as it sacrifices force control for much higher cycle rates.

- If your primary focus is creating complex shapes or deep-drawing: The precise control over speed and pressure in a hydraulic press makes it ideal for intricate forging and molding operations.

Ultimately, the hydraulic press stands as a testament to how a simple physical principle can be harnessed to create machines of incredible power and precision.

Summary Table:

| Key Concept | Description |

|---|---|

| Core Principle | Pascal's Law: Pressure applied to a confined fluid is transmitted equally and undiminished. |

| Force Multiplication | A small input force on a small piston creates pressure, generating a large output force on a larger piston. |

| Key Components | Hydraulic fluid, small piston (plunger), large piston (ram), and hydraulic cylinder. |

| Main Trade-off | High force output is achieved at the expense of speed; the system is slower but offers superior control. |

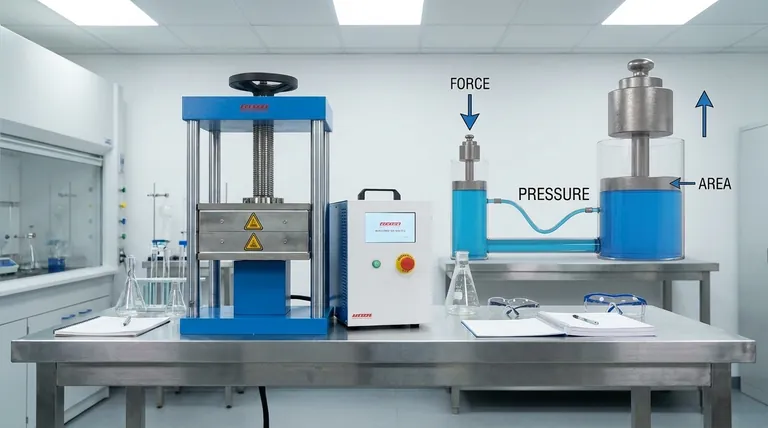

Need a reliable hydraulic press for your lab or production line?

KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision and power. Whether you're in materials testing, sample preparation, or R&D, our solutions deliver the controlled force you need.

Contact us today to find the perfect press for your application and experience the KINTEK difference in quality and support.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples