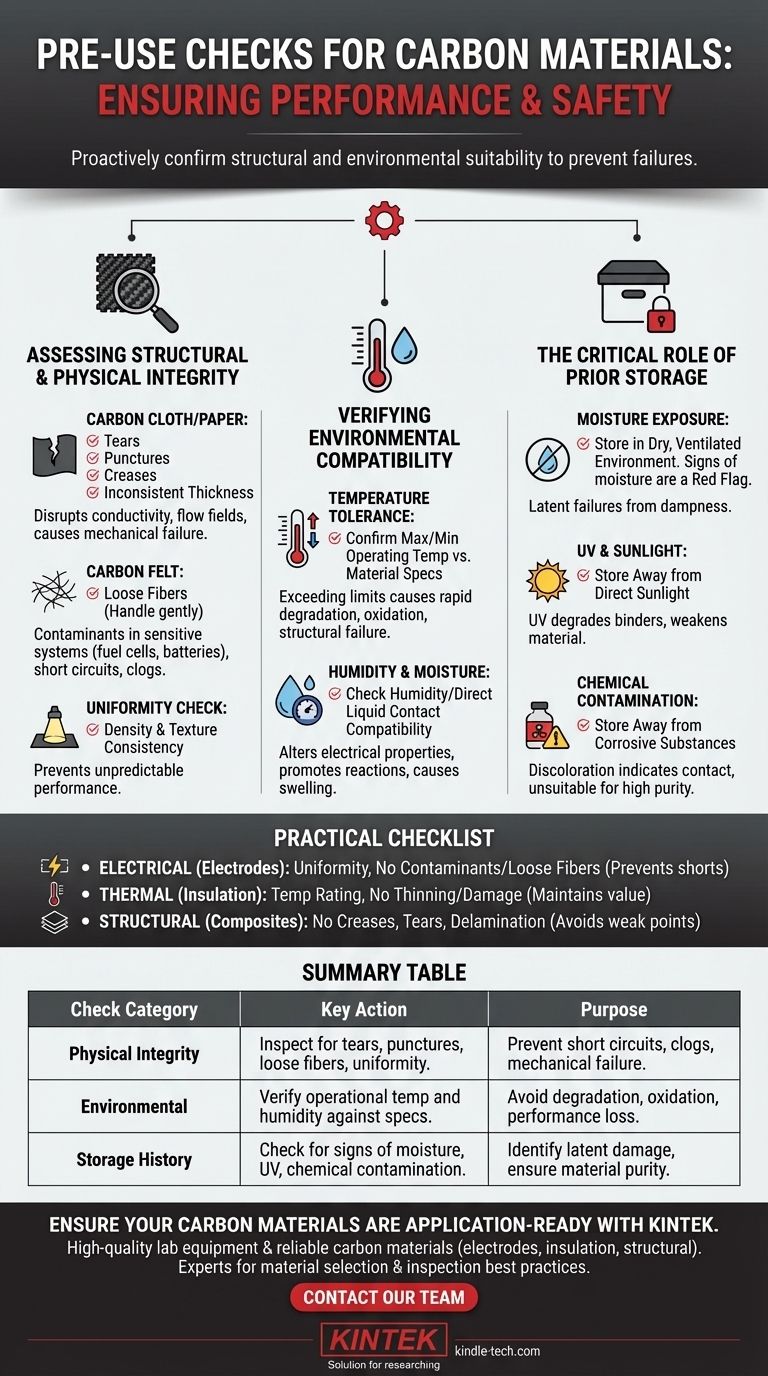

Before any application, your primary pre-use checks on carbon materials must cover two critical areas: a thorough visual inspection for physical integrity and a verification of the material's environmental tolerances against your specific use-case. This involves looking for damage like tears in carbon cloth or paper, checking for loose fibers in carbon felt, and confirming that your operational temperature and humidity are well within the material's specified limits.

The goal of a pre-use check is not simply to follow a list, but to proactively confirm the material's structural and environmental suitability. This simple step prevents catastrophic system failures, ensures performance reliability, and protects against wasted resources.

Assessing Structural and Physical Integrity

A material's physical condition is the most immediate indicator of its ability to perform. Even minor defects can compromise an entire system, especially in high-performance applications.

For Carbon Cloth and Paper

Inspect the material's surface for any signs of damage. This includes tears, punctures, deep creases, or areas of inconsistent thickness.

These flaws can disrupt electrical conductivity, create uneven flow fields for gases or liquids, or act as mechanical failure points under stress.

For Carbon Felt

The primary concern with carbon felt is the presence of loose fibers. Gently handle the material to see if fibers easily detach.

Loose fibers can become contaminants in sensitive systems, such as fuel cells or batteries, where they can cause short circuits or clog porous transport layers.

The Importance of Uniformity

Beyond obvious damage, look for overall consistency. Hold the material up to a light source to check for uniformity in density and texture.

Inconsistent patches can lead to unpredictable performance, whether the material is being used for electrical conductivity, thermal insulation, or as a structural component.

Verifying Environmental Compatibility

A structurally perfect material will still fail if it is used in an environment it was not designed for. This check requires you to compare the material's data sheet against your application's operational parameters.

Temperature Tolerance

Confirm the maximum and minimum operating temperatures of your application. Ensure these fall comfortably within the specified tolerance range of the carbon material.

Exceeding the material's temperature limit can lead to rapid degradation, oxidation, and complete structural failure.

Humidity and Moisture Levels

Carbon materials can be sensitive to moisture. Verify that the expected humidity or direct liquid contact in your process is compatible with the material.

Excess moisture can alter electrical properties, promote unwanted chemical reactions, or cause physical swelling in some carbon composites.

The Critical Role of Prior Storage

Many failures identified during pre-use checks are a direct result of improper storage. Verifying the material's history is as important as inspecting its current state.

The Impact of Moisture

Carbon materials must be stored in a dry, ventilated environment. Any sign of moisture exposure during a pre-use check is a major red flag.

Dampness can compromise the material long before it is put into service, leading to latent failures.

UV and Sunlight Degradation

Storage should always be away from direct sunlight. UV radiation can degrade binders within the carbon material, weakening it over time.

While not always visible, this degradation reduces the material's mechanical strength and can alter its surface properties.

Preventing Chemical Contamination

Materials should be stored away from any corrosive substances. Check for any discoloration or surface changes that might indicate accidental chemical contact.

Contamination can render the material entirely unsuitable for applications requiring high purity, such as in electrodes or catalysts.

A Practical Checklist for Your Application

Use your specific goal to determine which checks require the most attention.

- If your primary focus is high-performance electrical applications (e.g., electrodes): Your inspection must prioritize material uniformity and the absence of any contaminants or loose fibers that could cause short-circuiting.

- If your primary focus is high-temperature thermal insulation: The most critical check is confirming the material's temperature rating against your application's needs and looking for any thinning or damage that compromises its insulative value.

- If your primary focus is structural reinforcement or composites: Your search should be for any physical defects like creases, tears, or delamination that would create a definitive mechanical weak point.

Ultimately, these diligent pre-use inspections ensure that the material you start with is the material you need to succeed.

Summary Table:

| Check Category | Key Action | Purpose |

|---|---|---|

| Physical Integrity | Inspect for tears, punctures, loose fibers, and uniformity. | Prevent short circuits, clogs, and mechanical failure points. |

| Environmental Compatibility | Verify operational temperature and humidity against material specs. | Avoid degradation, oxidation, and performance loss. |

| Storage History | Check for signs of moisture, UV exposure, or chemical contamination. | Identify latent damage and ensure material purity. |

Ensure your carbon materials are application-ready and avoid costly downtime. KINTEK specializes in providing high-quality lab equipment and consumables, including reliable carbon materials for electrodes, thermal insulation, and structural composites. Our experts can help you select the right materials and establish best practices for inspection and handling. Contact our team today to discuss your specific laboratory needs and ensure peak performance in your applications.

Visual Guide

Related Products

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why graphite has high thermal conductivity? Unlock Superior Heat Management with Its Unique Structure

- Is graphite good in high temperature? Unlocking Its Extreme Heat Potential

- How is synthetic graphite manufactured? A Deep Dive into the High-Temperature Process

- Why does graphite not melt? Unlocking the Secrets of Its Extreme Heat Resistance

- Is a graphite melting point high or low? Discover Its Extreme Thermal Resilience