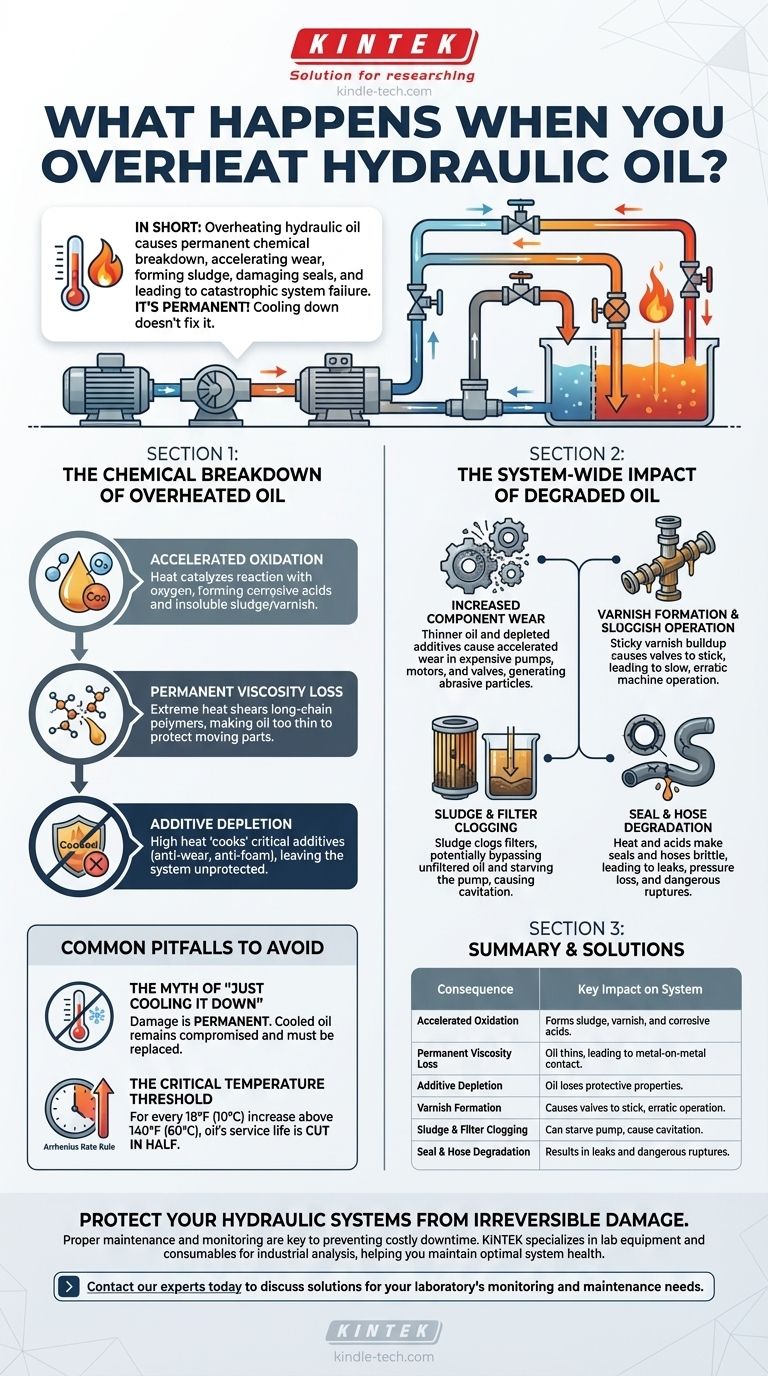

In short, overheating hydraulic oil causes it to permanently degrade, losing its essential properties. This chemical breakdown leads to accelerated wear on pumps and motors, formation of sludge that clogs components, and damage to seals, ultimately causing premature and often catastrophic system failure.

Overheating is not a temporary problem that is solved by cooling the system down. It inflicts irreversible chemical damage on the oil, cutting its lifespan in half for every 18°F (10°C) increase above 140°F (60°C) and silently setting the stage for component failure.

The Chemical Breakdown of Overheated Oil

When hydraulic oil exceeds its optimal operating temperature, typically above 180°F (82°C), a series of destructive chemical reactions begins. These reactions are not reversible.

Accelerated Oxidation

Heat acts as a catalyst, dramatically speeding up the oil's reaction with oxygen. This oxidation is the primary form of oil degradation.

The process creates corrosive acids that attack metal surfaces and soft components like seals. It also produces insoluble byproducts that manifest as sludge and varnish.

Permanent Viscosity Loss

Many hydraulic oils contain long-chain polymer additives to maintain a stable viscosity across a range of temperatures. Extreme heat permanently shears these polymers apart.

This results in a permanent drop in viscosity, meaning the oil becomes too thin. A thinner oil cannot maintain an adequate protective film between moving parts, leading to metal-on-metal contact.

Additive Depletion

Hydraulic oil is a complex formula of base oil and a precise additive package. These additives perform critical functions like preventing wear, corrosion, and foam.

High temperatures essentially "cook" these additives, causing them to either burn off, break down, or fall out of the solution. Once depleted, the oil can no longer protect the system as it was designed to.

The System-Wide Impact of Degraded Oil

The chemical damage to the oil translates directly into physical damage to the hydraulic system. This creates a vicious cycle where problems compound over time.

Increased Component Wear

With reduced viscosity and depleted anti-wear additives, the oil film separating critical components becomes ineffective. This causes accelerated wear in the most expensive parts of your system: pumps, motors, and valves.

This wear generates more metallic particles in the system, which act as an abrasive and further accelerate the wear process.

Varnish Formation and Sluggish Operation

Varnish is a sticky, lacquer-like byproduct of oxidation. It coats internal surfaces, particularly close-tolerance components like spools inside directional control valves.

This buildup causes valves to stick, leading to slow, erratic, and unpredictable machine operation. Varnish also acts as an insulator, reducing the system's ability to dissipate heat and making the overheating problem even worse.

Sludge and Filter Clogging

Sludge is the thicker, goo-like byproduct of oxidation. It accumulates in the reservoir, clogs suction strainers, and rapidly plugs hydraulic filters.

Clogged filters can lead to a bypass condition where unfiltered, contaminated oil is sent directly to sensitive components, causing rapid damage. Starving the pump of oil can also lead to cavitation and catastrophic failure.

Seal and Hose Degradation

The combination of high heat and the acidic byproducts of oxidation attacks the elastomers used in seals and hoses.

Materials become hard and brittle, losing their ability to seal effectively. This results in both internal and external leaks, loss of system pressure, and the potential for a dangerous hose rupture.

Common Pitfalls to Avoid

Understanding the reality of overheating helps avoid costly assumptions. The damage is often silent until it becomes catastrophic.

The Myth of "Just Cooling It Down"

The single most critical concept to understand is that the damage is permanent. Once the oil has been oxidized and its additives depleted, cooling it down does not restore its properties.

The oil is now compromised and must be replaced to prevent further system damage. Running a system with thermally damaged oil is a direct path to premature component failure.

The Critical Temperature Threshold

While specific limits vary by oil type, a universal rule of thumb is the Arrhenius Rate Rule: for every 18°F (10°C) increase in temperature above 140°F (60°C), the oil's service life is cut in half.

A system running at 176°F (80°C) will degrade its oil four times faster than one running at 140°F (60°C). This exponential rate is why managing temperature is not just a suggestion, but a requirement.

Making the Right Choice for Your System

Preventing overheating is always more cost-effective than dealing with its consequences. Your strategy should be proactive, focusing on design, maintenance, and operation.

- If your primary focus is system design: Ensure the hydraulic reservoir is large enough and the heat exchanger (oil cooler) is correctly sized to dissipate the system's expected heat load.

- If your primary focus is maintenance: Implement a routine oil analysis program to detect thermal breakdown and additive depletion before they cause failure. Regularly clean oil cooler fins and change filters.

- If your primary focus is reliable operation: Avoid continuously running the system over a pressure relief valve, as this is a primary source of intense, localized heat generation.

Ultimately, managing heat is the single most important factor in ensuring the long-term health and reliability of any hydraulic system.

Summary Table:

| Consequence of Overheating | Key Impact on System |

|---|---|

| Accelerated Oxidation | Forms sludge, varnish, and corrosive acids. |

| Permanent Viscosity Loss | Oil thins, leading to metal-on-metal contact and wear. |

| Additive Depletion | Oil loses its protective properties (anti-wear, anti-foam). |

| Varnish Formation | Causes valves to stick and leads to erratic operation. |

| Sludge & Filter Clogging | Can starve the pump and cause cavitation. |

| Seal & Hose Degradation | Results in leaks and potential for dangerous ruptures. |

Protect your hydraulic systems from the irreversible damage of overheating. Proper maintenance and monitoring are key to preventing costly downtime and component failure. KINTEK specializes in lab equipment and consumables for industrial analysis, helping you maintain optimal system health. Contact our experts today to discuss solutions for your laboratory's monitoring and maintenance needs.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

People Also Ask

- How can you improve corrosion resistance? Extend Equipment Life with Proven Strategies

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges

- What are two disadvantages of metal? Understanding Corrosion and Weight Limitations

- What products are manufactured with titanium? The Ultimate Guide to High-Performance Materials

- Why is platinum unreactive? The Atomic Secrets Behind Its Remarkable Stability