In short, hydraulic presses are foundational tools used across nearly every major industrial sector, including automotive, aerospace, metal fabrication, construction, and general manufacturing. Their primary function is to apply immense, controlled force to shape, form, assemble, or test a vast range of materials.

The true value of a hydraulic press isn't just its raw power; it's the precise control and unmatched versatility it offers. This combination allows industries to manipulate everything from delicate ceramics to high-strength steel with extreme accuracy, making it an indispensable engine of modern production.

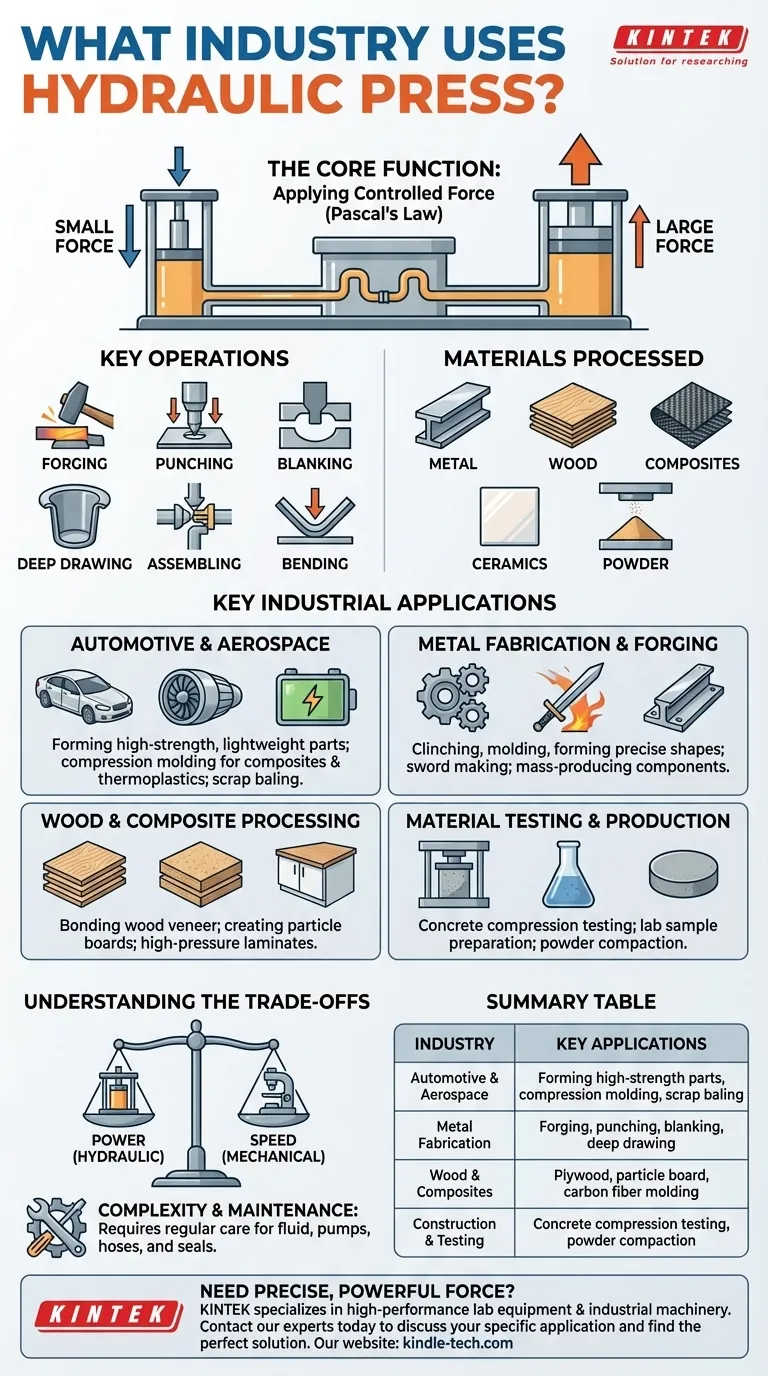

The Core Function: Applying Controlled Force

At its heart, a hydraulic press uses a simple principle—Pascal's law—to multiply a small amount of force into an immense amount of pressure. This capability is the reason for its widespread adoption.

From Shaping to Assembling

A hydraulic press is not a single-purpose tool. Its controlled force enables a wide variety of operations.

These include fundamental processes like forging, punching, blanking (cutting shapes from sheet metal), and deep drawing (forming cup-like shapes). It is also used for assembling parts and bending materials.

Versatility Across Materials

The applications are not limited to just metal. Hydraulic presses are critical for working with a diverse set of materials.

This includes wood processing (like making plywood and particle boards), composites (like carbon fiber), ceramics, and even powder compacting for everything from creating machine parts to producing fat-free cocoa powder.

Key Industrial Applications

The versatility of the hydraulic press means it appears in highly specialized roles across numerous high-stakes industries.

Automotive and Aerospace Manufacturing

These sectors rely on hydraulic presses to form high-strength, lightweight parts that are critical for safety, structural integrity, and fuel efficiency.

This includes traditional metal forming as well as advanced compression molding for thermoplastics and carbon fiber composites, which are essential for both modern aircraft and electric vehicles (EVs). On the other end of the lifecycle, they are used for crushing and baling scrap cars.

Metal Fabrication and Forging

In metal fabrication, hydraulic presses perform essential tasks like clinching, molding, and forming metal into precise shapes.

This can range from mass-producing automotive components to the highly specialized and ancient craft of sword making, where controlled force is needed to shape the blade.

Wood and Composite Processing

The press is essential for creating engineered wood products.

It applies heat and pressure to bond layers of wood veneer into plywood, create particle boards, and form high-pressure laminates used for countertops and furniture.

Material Testing and Production

Beyond manufacturing, hydraulic presses serve a critical role in quality control and material science.

They are used for concrete compression testing to ensure structural safety, preparing laboratory samples, and compacting powders to create uniform ceramic parts.

Understanding the Trade-offs

While incredibly versatile, the hydraulic press is not the solution for every application. Understanding its limitations is key to appreciating its role.

The Power vs. Speed Dilemma

The defining characteristic of a hydraulic press is its ability to deliver massive, constant force throughout its stroke.

However, this typically comes at the cost of speed. For high-speed, repetitive operations like simple stamping, a mechanical press is often the faster and more efficient choice.

Complexity and Maintenance

Hydraulic systems rely on fluids, pumps, hoses, and seals. This complexity means they require regular, diligent maintenance to prevent leaks and ensure consistent performance.

Failure to maintain the hydraulic system can lead to costly downtime and inconsistent product quality.

Making the Right Choice for Your Goal

The decision to use a hydraulic press is driven by the specific demands of the material and the desired outcome.

- If your primary focus is forming complex, high-strength parts: A hydraulic press offers the sustained, controllable pressure needed for deep drawing and molding advanced materials like composites and high-strength steel.

- If your primary focus is creating dense, uniform materials: The consistent force of a hydraulic press is ideal for powder compaction in ceramics or creating engineered wood products like plywood.

- If your primary focus is quality control and testing: The precise and measurable force application makes hydraulic presses the standard for destructive and non-destructive material testing.

Ultimately, the hydraulic press remains a cornerstone of industry because it provides a powerful, adaptable, and precise method for transforming raw materials into finished goods.

Summary Table:

| Industry | Key Applications |

|---|---|

| Automotive & Aerospace | Forming high-strength parts, compression molding, scrap baling |

| Metal Fabrication | Forging, punching, blanking, deep drawing |

| Wood & Composites | Plywood, particle board, carbon fiber molding |

| Construction & Testing | Concrete compression testing, powder compaction |

Need precise, powerful force for your manufacturing or testing processes? KINTEK specializes in high-performance lab equipment and industrial machinery. Whether you're in automotive, aerospace, or advanced materials development, our expertise can help you select the right hydraulic press to enhance your production quality and efficiency. Contact our experts today to discuss your specific application and find the perfect solution for your needs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep