In short, a 100-ton press is a powerful and versatile industrial tool used to bend, form, straighten, and assemble heavy-duty materials. Its primary function is to apply a massive, controlled force—equivalent to 200,000 pounds—to a workpiece, making it a cornerstone of metal fabrication shops, heavy equipment repair facilities, and manufacturing plants.

The "100-ton" rating signifies more than just raw power; it represents a critical capability threshold. This level of force is where a press transitions from a basic shop tool into a serious industrial machine capable of permanently deforming substantial cross-sections of steel and other metals.

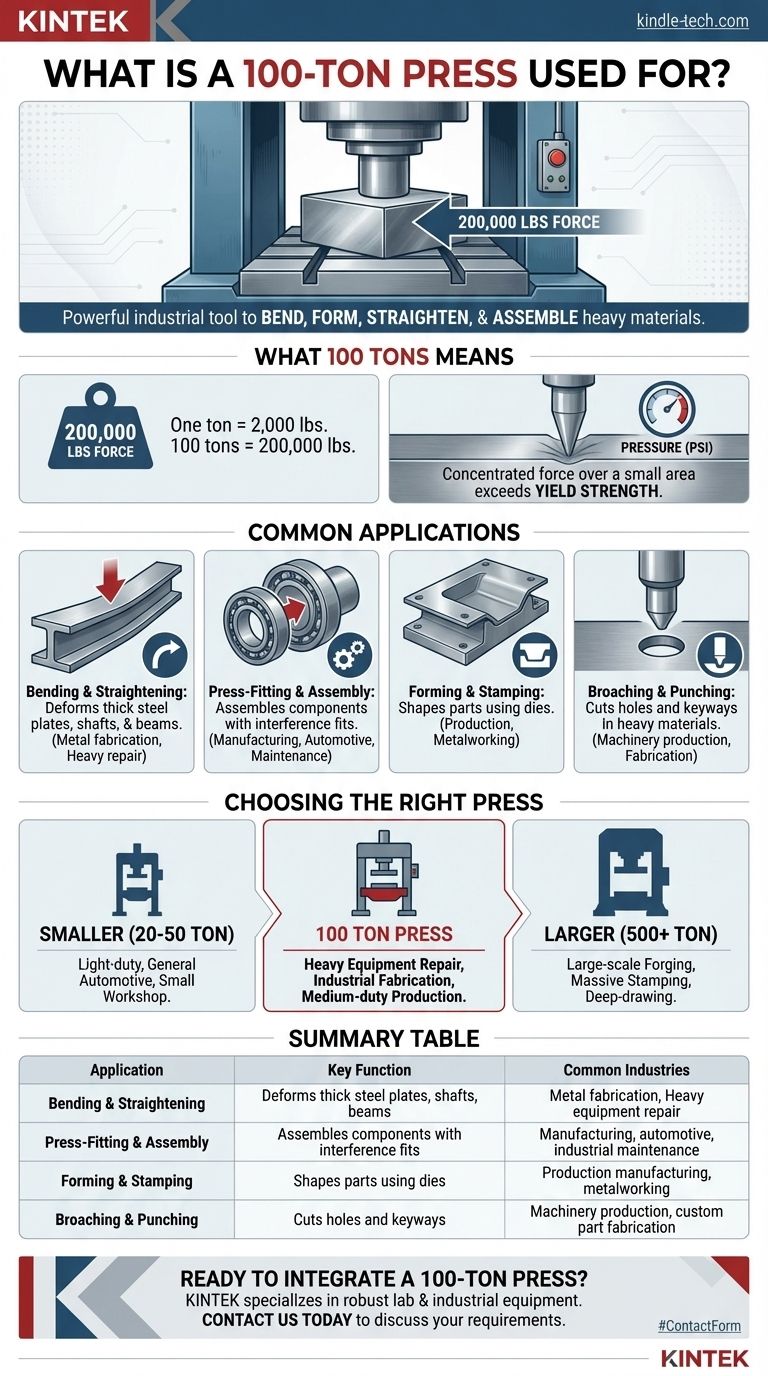

What "100 Tons of Force" Actually Means

To understand the applications, you first need to grasp what this measurement represents. It's not just about weight, but about the immense pressure the machine can generate.

A Quick Physics Refresher

The "ton" in this context refers to a unit of force, not mass. One ton of force is 2,000 pounds. Therefore, a 100-ton press can exert a maximum downward force of 200,000 pounds.

The Importance of Pressure (PSI)

Force alone doesn't tell the whole story. The true work is done by pressure, which is the force applied over a specific area (Pounds per Square Inch or PSI).

A 100-ton press concentrates that 200,000 pounds of force onto a relatively small point of contact, like the tip of a ram or a die. This concentration generates incredibly high PSI, which is what allows it to exceed the material's yield strength and force it to change shape.

The Threshold for Metal Deformation

Every material has a yield strength—the point at which it stops flexing and starts to permanently bend or deform. A 100-ton press provides enough force to easily overcome the yield strength of thick steel plates, solid shafts, and other robust components.

Common Applications for a 100-Ton Press

This level of force opens up a wide range of industrial processes that smaller presses simply cannot handle.

Bending and Straightening

This is one of the most common uses. A 100-ton press is ideal for straightening bent axle shafts, correcting warped steel plates, or putting precise bends into heavy structural beams used in fabrication.

Press-Fitting and Assembly

The controlled force is perfect for assembling components with an interference fit. This includes pressing large bearings into housings, inserting bushings into heavy equipment arms, or seating gears onto shafts.

Forming and Stamping

In manufacturing, these presses are used with dies to stamp or form parts from thick sheet metal. This could involve creating automotive brackets, industrial enclosures, or other custom-formed components.

Broaching and Punching

When fitted with the right tooling, a 100-ton press can punch clean holes through thick steel plate or be used for broaching operations, such as cutting internal keyways in gears and pulleys.

Understanding the Trade-offs

A 100-ton press is a formidable tool, but it isn't the right choice for every task. Objectivity is key to selecting the right equipment.

When 100 Tons Isn't Enough

For very large-scale industrial operations like forging massive steel billets, stamping entire car body panels, or deep-drawing complex shapes, much higher tonnages (500 to 2,000+ tons) are required.

When a Smaller Press is Better

For many common tasks in a smaller machine shop or automotive garage, 100 tons is overkill. A 20- or 50-ton press is more than sufficient—and more cost-effective—for pressing smaller bearings, U-joints, or performing light-duty bending.

The Cost and Footprint Factor

A 100-ton press represents a significant investment and requires a large, dedicated footprint with a robust foundation. It is the dividing line between a standard shop press and true heavy industrial machinery.

Making the Right Choice for Your Goal

The ideal press tonnage is dictated entirely by the material, its thickness, and the operation you need to perform.

- If your primary focus is heavy equipment repair or industrial fabrication: A 100-ton press offers the power and versatility needed for straightening large shafts, bending thick plate, and handling heavy-duty bearings.

- If your primary focus is production stamping or forming: You must calculate the required tonnage for your specific die and material; 100 tons is a capable starting point for many medium-duty parts.

- If your primary focus is general automotive or a small workshop: A 20 to 50-ton press is a more practical and cost-effective choice for the vast majority of tasks you will encounter.

Ultimately, choosing the right press comes down to matching the force to the specific demands of your work.

Summary Table:

| Application | Key Function | Common Industries |

|---|---|---|

| Bending & Straightening | Permanently deforms thick steel plates, shafts, and beams | Metal fabrication, heavy equipment repair |

| Press-Fitting & Assembly | Assembles components with interference fits (bearings, bushings, gears) | Manufacturing, automotive, industrial maintenance |

| Forming & Stamping | Shapes parts using dies for custom brackets and enclosures | Production manufacturing, metalworking |

| Broaching & Punching | Cuts holes and keyways in heavy materials | Machinery production, custom part fabrication |

Ready to integrate a 100-ton press into your workflow?

A 100-ton press is a cornerstone of serious metal fabrication and heavy equipment repair. Whether your goal is to straighten massive shafts, assemble heavy-duty components, or stamp custom parts, having the right equipment is critical for efficiency and safety.

At KINTEK, we specialize in robust lab and industrial equipment, including powerful presses designed for demanding applications. Our expertise helps you select the right machinery to match your specific material and operational needs, ensuring you invest in a solution that maximizes productivity.

Contact us today using the form below to discuss your requirements and discover how a KINTEK press can enhance your capabilities.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability