In essence, a batch furnace is an industrial oven that thermally processes one discrete load, or "batch," of material at a time. Unlike a continuous furnace where parts move through constantly, a batch furnace treats a stationary load through a complete heating and cooling cycle before the next load is introduced.

The core distinction is one of philosophy: batch furnaces are built for flexibility and precision, making them ideal for variable production needs and sensitive processes. Continuous furnaces, in contrast, are built for throughput and efficiency in mass production environments.

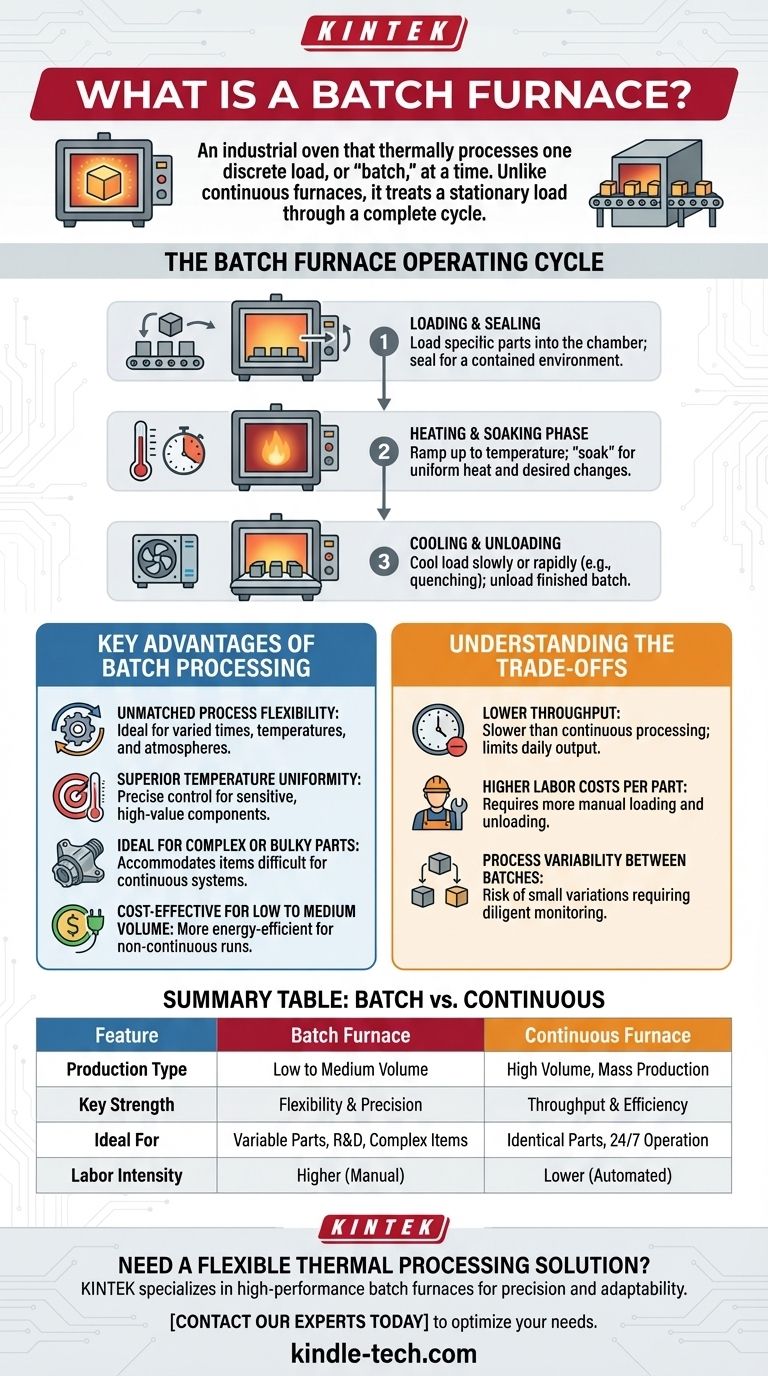

The Batch Furnace Operating Cycle

Understanding a batch furnace is best done by looking at its distinct operational steps. The entire process is a self-contained cycle for a single load.

Loading and Sealing

The cycle begins by loading a specific quantity of parts into the furnace chamber. This can be done manually or with automated systems. Once loaded, the furnace door is sealed to create a contained environment.

The Heating and Soaking Phase

The furnace then ramps up to a specific target temperature according to a pre-programmed profile. Once at temperature, the load "soaks" for a designated period to ensure every part reaches a uniform temperature and the desired metallurgical or chemical changes occur.

Cooling and Unloading

After the soak is complete, the load is cooled. This can happen slowly inside the furnace, or more rapidly through forced air, inert gas, or by moving the load to a separate quenching tank. Once cooled to a safe handling temperature, the furnace is opened and the finished batch is unloaded.

Key Advantages of Batch Processing

Choosing a batch furnace is a strategic decision driven by several key benefits that are critical for certain manufacturing goals.

Unmatched Process Flexibility

The primary advantage is flexibility. Each batch can be run with a completely different time, temperature, and atmosphere profile. This is ideal for job shops or R&D labs that handle a wide variety of parts and process requirements.

Superior Temperature Uniformity

Because the load is stationary, it's easier to achieve excellent temperature uniformity throughout the chamber. This precise control is critical for heat-treating sensitive, high-value components where consistent material properties are non-negotiable.

Ideal for Complex or Bulky Parts

Batch furnaces can be designed to accommodate very large, heavy, or awkwardly shaped parts that would be difficult or impossible to move through a continuous system.

Cost-Effective for Low to Medium Volume

For production that is not continuous, a batch furnace can be more energy-efficient. It can be turned on to run a cycle and then idled or shut down, avoiding the cost of keeping a large continuous furnace at temperature 24/7.

Understanding the Trade-offs

While powerful, batch furnaces are not the right solution for every application. Their flexibility comes with clear trade-offs.

Lower Throughput

By its very nature, batch processing is slower than continuous processing. The time spent loading, unloading, heating, and cooling for each cycle limits the total number of parts that can be processed per day. This makes it unsuitable for high-volume, commodity-style production.

Higher Labor Costs Per Part

Batch operations often require more manual intervention for loading and unloading compared to the highly automated nature of continuous lines. This can translate to a higher labor cost per individual part processed.

Process Variability Between Batches

While control within a single batch is excellent, there is a small risk of slight variations from one batch to the next. This requires diligent process monitoring to ensure perfect consistency across a full production run.

Making the Right Choice for Your Process

The decision between a batch and continuous furnace hinges entirely on your specific production goals and part requirements.

- If your primary focus is high-volume production of identical parts: A continuous furnace will almost always provide a lower cost per part and higher throughput.

- If your primary focus is process flexibility for varied parts or recipes: A batch furnace is the ideal choice for its ability to adapt to different requirements on a cycle-by-cycle basis.

- If your primary focus is absolute precision for high-value, complex, or large components: A batch furnace offers superior control over temperature uniformity and process parameters.

Ultimately, selecting the right furnace is about aligning the equipment's core strengths with your specific manufacturing strategy.

Summary Table:

| Feature | Batch Furnace | Continuous Furnace |

|---|---|---|

| Production Type | Low to Medium Volume | High Volume, Mass Production |

| Key Strength | Flexibility & Precision | Throughput & Efficiency |

| Ideal For | Variable Parts, R&D, Complex/Bulky Items | Identical Parts, 24/7 Operation |

| Labor Intensity | Higher (Manual Loading/Unloading) | Lower (Highly Automated) |

Need a flexible thermal processing solution for your unique parts?

KINTEK specializes in high-performance batch furnaces designed for precision, control, and adaptability. Whether you're in a job shop, R&D lab, or need to process large, complex components, our equipment delivers the superior temperature uniformity and process flexibility you require.

Contact our experts today to discuss how a KINTEK batch furnace can optimize your specific laboratory or production needs.

Visual Guide

Related Products

- Mesh belt controlled atmosphere furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- Why is a high-precision atmosphere furnace essential for high-nickel cathode sintering? Unlock Battery Performance

- What is the function of a tube atmosphere furnace in Li2MnSiO4 synthesis? Achieve High-Purity Battery Materials

- Why Use Ultra-High Vacuum Furnaces for LLZO? Ensure Chemical Stability & Interface Integrity in Solid Electrolytes

- Why is a horizontal tube furnace with a H2-N2 atmosphere used for NiO pre-treatment? Key to Catalyst Activation