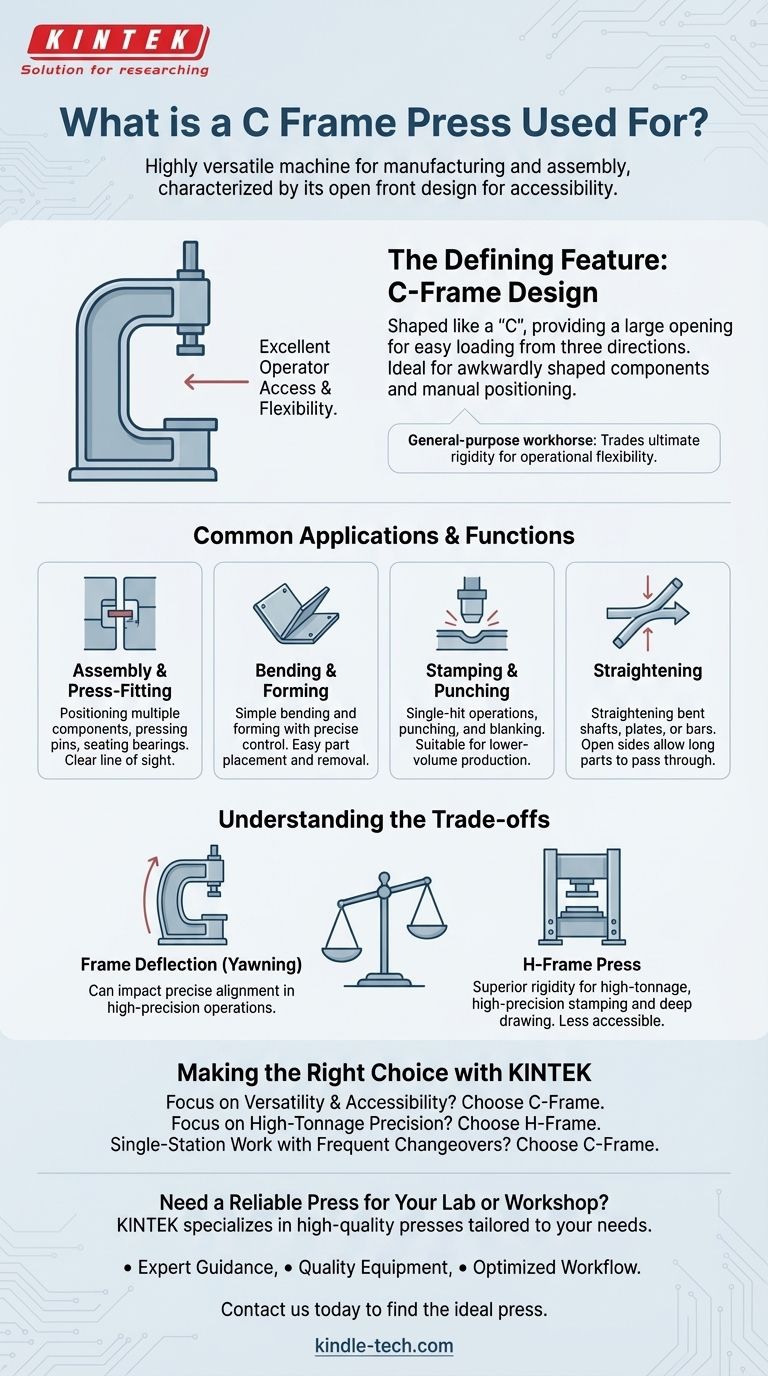

At its core, a C frame press is a highly versatile machine used for a wide range of manufacturing and assembly tasks. Because of its open front design, it is exceptionally well-suited for applications like assembling components, bending metal, light stamping, straightening parts, riveting, and performing press-fit operations where operator access is critical.

The defining feature of a C frame press isn't just the force it delivers, but the accessibility it provides. Its open-gap design makes it a general-purpose workhorse for tasks that require easy loading and manipulation of parts, trading ultimate rigidity for operational flexibility.

What Defines a C Frame Press?

A C frame press, also known as an open gap frame press, gets its name from its distinct physical shape. Understanding this design is key to understanding its function.

The "C" Shape and Open Front

The press's frame is shaped like the letter "C," creating a large, unobstructed opening at the front and sides. This is the machine's primary advantage.

This design allows operators to easily load and unload parts from three directions, making it far more accessible than other press designs. It is ideal for processes involving awkwardly shaped components or those that require manual positioning.

How It Works: Controlled Force

Most C frame presses are hydraulic, meaning they use a fluid-filled cylinder and piston to generate compressive force. This system allows for precise control over the ram's speed, pressure, and position throughout the stroke.

This level of control is essential for delicate operations like press-fitting a bearing without damaging it or performing a precise bend in a piece of sheet metal.

A Breakdown of Common Applications

The C frame's blend of power and accessibility makes it a fixture in machine shops and assembly lines. It excels in tasks where single-station work is performed.

Assembling and Press-Fitting

The open design provides ample room to position two or more components, such as pressing a pin into a hole or seating a bearing in its housing. Operators have a clear line of sight and space to work.

Bending and Forming

For simple bending and forming operations, a C frame press provides the necessary force. Its accessibility allows the operator to easily place, adjust, and remove the workpiece between cycles.

Stamping and Punching

While not intended for heavy-duty progressive die stamping, a C frame is excellent for single-hit stamping, punching, and blanking operations. It's often used for lower-volume production or secondary operations.

Straightening

When a shaft, plate, or bar is bent or warped, a C frame press is the go-to tool for straightening. The open sides allow long parts to pass through the frame, and the operator can make precise, incremental adjustments.

Understanding the Trade-offs

No single machine design is perfect for every job. The C frame's greatest strength—its open front—is also the source of its primary limitation.

The Limitation: Frame Deflection ("Yawning")

Under extremely high tonnage, the open "C" structure has a tendency to flex or "yawn." The top and bottom of the C can spread apart slightly, which can impact the precise alignment between the ram and the bed.

This deflection is a critical consideration for high-precision coining or deep-drawing operations where maintaining perfect parallelism is non-negotiable.

When to Choose an H-Frame Press

For applications requiring very high tonnage and maximum rigidity, an H-frame press (also called a straight-side or 4-post press) is superior. Its closed, box-like structure is inherently more resistant to deflection under load.

H-frame presses are the standard for heavy stamping, deep drawing, and molding, where minimizing frame stretch is essential for die life and part consistency. However, this rigidity comes at the cost of accessibility.

Making the Right Choice for Your Goal

Selecting the correct press requires matching the machine's capabilities to your specific application.

- If your primary focus is versatility and accessibility: A C frame press is the ideal workhorse for a wide range of general-purpose assembly, fabrication, and repair tasks.

- If your primary focus is high-tonnage precision: You should evaluate an H-frame press for its superior rigidity in demanding stamping or deep-drawing operations.

- If your primary focus is single-station work with frequent changeovers: The C frame's open design and ease of access will significantly improve your workflow efficiency.

By understanding the inherent trade-off between accessibility and rigidity, you can confidently select the press that best serves your operational needs.

Summary Table:

| Key Feature | Description |

|---|---|

| Primary Use | Assembly, bending, light stamping, straightening, riveting, and press-fit operations. |

| Main Advantage | Open-front "C" shape design for excellent operator access from three sides. |

| Typical Power Source | Hydraulic, allowing for precise control of force, speed, and position. |

| Ideal For | Single-station work, frequent changeovers, and applications requiring manual part handling. |

| Main Limitation | Frame deflection ("yawning") under very high tonnage, affecting precision alignment. |

| Alternative for Heavy Duty | H-frame press for high-tonnage, high-precision stamping and deep drawing. |

Need a Reliable Press for Your Lab or Workshop?

Choosing the right equipment is critical for your productivity and results. At KINTEK, we specialize in providing high-quality lab equipment, including robust presses tailored to your specific needs. Whether you're assembling components, performing press-fit operations, or require precise bending capabilities, our team can help you select the perfect solution.

Let KINTEK empower your work:

- Expert Guidance: Get personalized advice to choose between a versatile C-frame press or a rigid H-frame press based on your application.

- Quality Equipment: Access reliable and durable machinery designed for precision and long-term performance in laboratory and industrial settings.

- Optimized Workflow: Enhance your efficiency with equipment that matches your operational requirements for single-station work and frequent changeovers.

Contact us today to discuss your project and find the ideal press for your laboratory needs. Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the difference between fused bead and pressed pellets? Choose the Right XRF Sample Prep Method

- Why is a high-precision laboratory hydraulic press necessary for radiation-shielding? Ensure Data Accuracy & Density

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing

- How do a precision laboratory hydraulic press and specialized molds contribute to the fabrication of spherical ceramic samples? Achieving High-Density Material Precision

- What is the difference between a manual press and a hydraulic press? Manual vs. Automatic Control Explained

- What is the difference between plate and frame filter press? A Guide to Choosing the Right Dewatering Technology

- How often do hydraulics need maintenance? A Guide to Condition-Based Reliability

- How does axial pressure influence Al2O3-TiCN/Co-Ni ceramics? Optimize Densification and Microstructure