In essence, a dental press is a specialized furnace that uses heat and pressure to transform a ceramic ingot into a high-strength, aesthetic dental restoration. It is the central piece of equipment in the "pressable ceramics" technique, used to create crowns, veneers, inlays, and onlays with exceptional precision and lifelike appearance.

The core function of a dental press is to accurately fabricate dental restorations by pressing molten ceramic material into a detailed mold. This technique is renowned for producing restorations with superior marginal fit and natural aesthetics compared to many other methods.

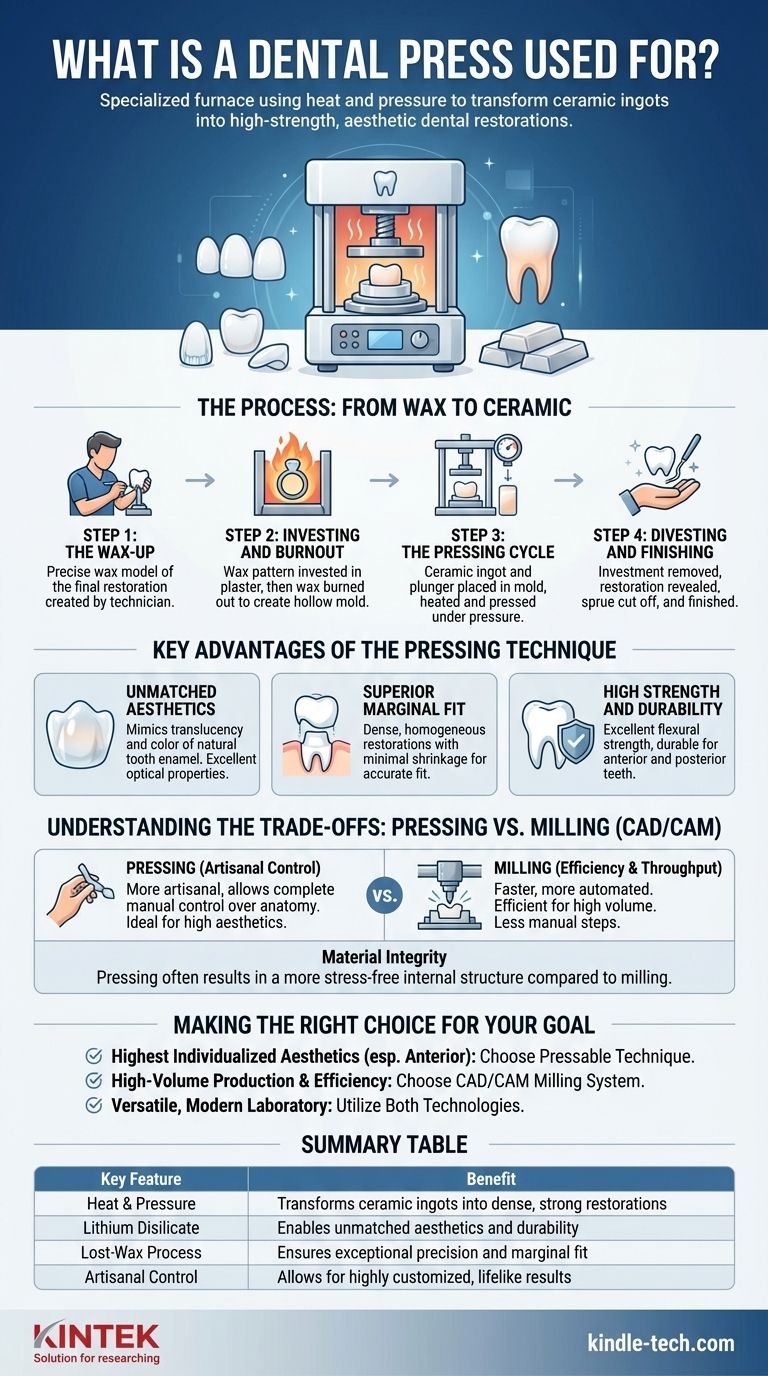

The Process: From Wax to Ceramic

The pressable technique is a highly controlled process that bridges traditional hands-on artistry with modern material science. It functions similarly to the lost-wax casting method used for centuries in jewelry and metalwork.

Step 1: The Wax-Up

A dental technician first creates a precise model of the final restoration using a special type of wax. This "wax-up" is a perfect, full-contour replica of the crown or veneer that is being made.

Step 2: Investing and Burnout

The wax pattern is attached to a sprue (a small wax channel) and placed inside a metal ring, which is then filled with a plaster-like material called investment. Once hardened, this ring is placed in a burnout oven.

The oven heats up slowly, melting and completely eliminating the wax, leaving behind a hollow, negative-space mold within the investment material.

Step 3: The Pressing Cycle

A pre-made ceramic ingot (most commonly lithium disilicate or leucite-reinforced glass-ceramic) and a ceramic plunger are placed into the hot mold. The entire assembly is then put into the dental press.

The press heats the ingot to its specific viscous temperature—hot enough to flow but not fully liquid. It then applies precise pneumatic or mechanical pressure, forcing the softened ceramic through the sprue channel and into every detail of the hollow mold.

Step 4: Divesting and Finishing

After the pressing cycle is complete, the investment ring is allowed to cool. The technician carefully breaks away the investment material (divesting) to reveal the newly formed ceramic restoration.

The final steps involve cutting off the sprue, finishing the margins, and applying custom stains and glazes to perfectly match the patient's natural teeth before a final firing in a porcelain furnace.

Key Advantages of the Pressing Technique

Dental professionals choose this method for several critical clinical and aesthetic reasons.

Unmatched Aesthetics

Pressable ceramics, particularly lithium disilicate (e.g., Ivoclar Vivadent's IPS e.max Press), are known for their excellent optical properties. They can mimic the translucency, opalescence, and color of natural tooth enamel with remarkable accuracy.

Superior Marginal Fit

The pressing process results in incredibly dense and homogeneous restorations that undergo minimal shrinkage. This leads to a highly accurate fit against the prepared tooth, which is critical for preventing leakage and secondary decay.

High Strength and Durability

Modern pressable materials offer excellent flexural strength, making them durable enough for both anterior (front) and posterior (back) teeth, providing a long-lasting and reliable clinical solution.

Understanding the Trade-offs: Pressing vs. Milling (CAD/CAM)

The main alternative to pressing is milling restorations from a solid block of ceramic using a CAD/CAM system. Each has distinct trade-offs.

Artistry and Control

Pressing is often considered a more artisanal technique. It allows a skilled technician to have complete manual control over the anatomy and contour of the wax-up, which directly translates to the final restoration.

Efficiency and Throughput

CAD/CAM milling is generally a faster, more automated process, making it highly efficient for labs with high production volumes. It eliminates the manual steps of waxing and investing.

Material Integrity

While both methods produce strong restorations, some argue that pressing a monolithic ingot under heat and pressure creates a more stress-free internal structure compared to grinding a restoration from a block, which can introduce micro-fractures. However, modern milling techniques have largely mitigated this concern.

Making the Right Choice for Your Goal

The decision between pressing and milling often depends on the specific clinical case and the philosophy of the dental lab.

- If your primary focus is on the highest level of individualized aesthetics, especially for anterior cases: The pressable technique offers unparalleled control for achieving lifelike results.

- If your primary focus is on high-volume production and workflow efficiency: A CAD/CAM milling system provides a faster, more automated solution.

- If your primary focus is a versatile, modern laboratory: Many advanced labs utilize both technologies, choosing the press for complex aesthetic cases and the mill for its speed and efficiency on others.

Ultimately, the dental press is an indispensable tool for any dental professional dedicated to fabricating restorations with the highest standards of form, fit, and function.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Heat & Pressure | Transforms ceramic ingots into dense, strong restorations |

| Lithium Disilicate | Enables unmatched aesthetics and durability |

| Lost-Wax Process | Ensures exceptional precision and marginal fit |

| Artisanal Control | Allows for highly customized, lifelike results |

Ready to elevate your dental lab's capabilities?

Whether you specialize in complex aesthetic cases or require reliable, high-strength restorations, a dental press is a cornerstone of quality. KINTEK specializes in precision lab equipment, including dental presses and furnaces, to help you achieve superior results for your patients.

Contact our experts today to find the perfect press for your laboratory's needs and discover how we can support your success.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects