At its core, a frame press is a machine tool designed to apply immense, controlled force. It is most commonly used for a wide range of workshop and industrial applications, including assembling parts via press-fitting, bending or straightening metal, stamping shapes, and riveting components together.

The true value of a frame press, particularly the common "C-frame" or "open gap" design, lies in its combination of powerful hydraulic force and an accessible frame that allows for easy manipulation of a wide variety of workpieces.

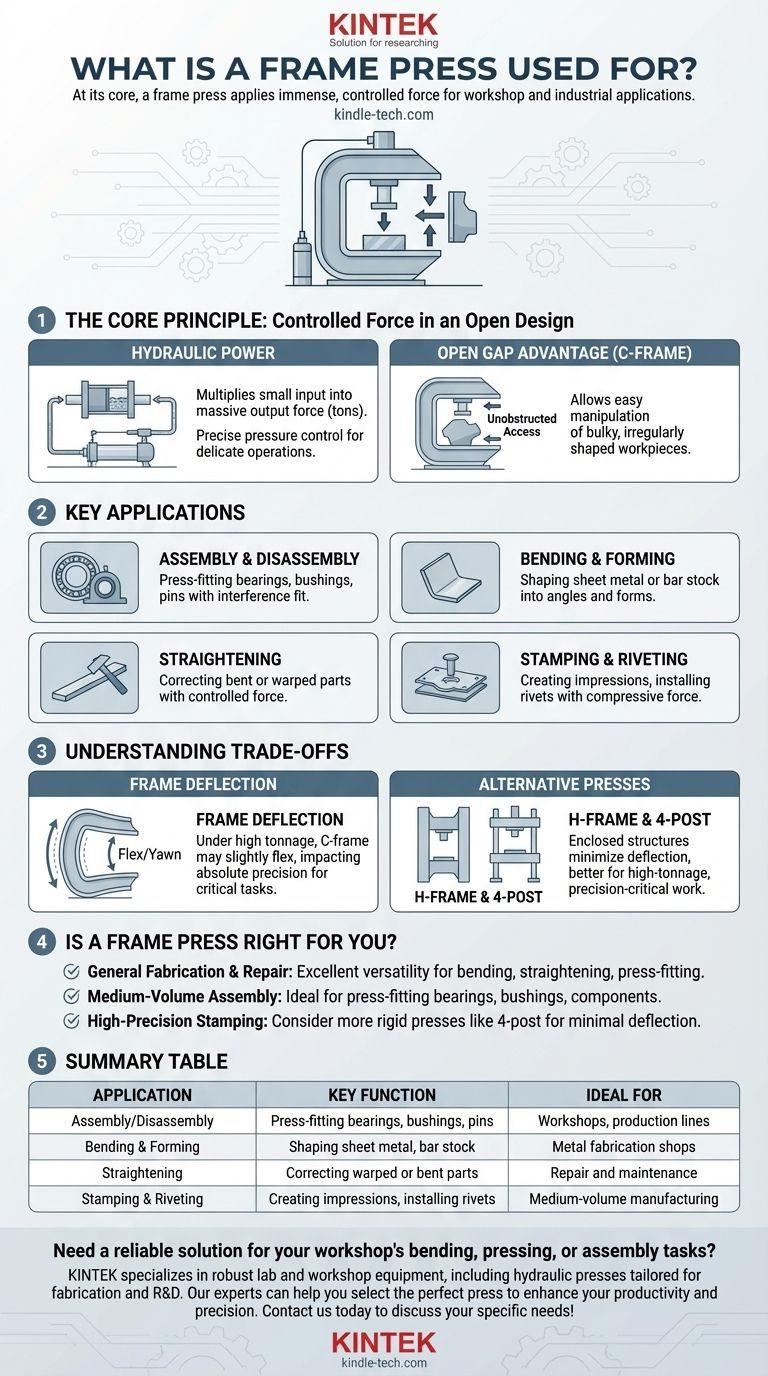

The Core Principle: Controlled Force in an Open Design

To understand what a frame press is used for, you must first understand its two fundamental characteristics: its power source and its physical structure. These two elements define its capabilities and limitations.

How It Works: The Power of Hydraulics

Most modern frame presses are hydraulic. They use a fluid-power system to multiply a small input force into a massive output force, measured in tons.

This hydraulic system allows for extremely precise control over the pressure applied to the workpiece, which is critical for delicate assembly operations and repeatable bending tasks.

The "Open Gap" Advantage: Accessibility and Versatility

The most common type is the C-frame press, also known as an open gap press. Its frame is shaped like the letter "C," leaving three sides of the work area open.

This open design is its greatest strength. It provides unobstructed access for operators to load, position, and unload bulky or awkwardly shaped parts, making it far more versatile than presses with enclosed frames.

Key Applications in Detail

The combination of controlled power and an accessible frame makes this tool a cornerstone of many fabrication shops and production lines.

Assembling and Disassembling

A primary use is for press-fit operations. This involves forcing parts like bearings, bushings, or pins into or out of a housing with a precise interference fit that holds them in place without fasteners.

Bending and Forming

The press is ideal for bending and forming sheet metal or bar stock into specific angles and shapes. By using different sets of dies, a single press can perform a variety of forming tasks.

Straightening

Frame presses are frequently used for straightening parts that have been bent or warped during manufacturing, shipping, or use. The controlled application of force allows an operator to carefully correct these deformities.

Stamping and Riveting

With the right tooling, a frame press can be used for stamping operations, such as creating impressions, logos, or shallow forms in metal. It is also used to install rivets by applying the necessary compressive force to form the rivet head.

Understanding the Trade-offs

While incredibly versatile, the C-frame press is not the ideal solution for every task. Its primary strength—the open frame—is also the source of its main limitation.

The Challenge of Deflection

Under extremely high tonnage, the open "C" shape has a tendency to flex or "yawn" slightly. This phenomenon, known as frame deflection, can impact the absolute precision of the operation.

For most general fabrication, bending, and assembly work, this minor deflection is not a concern. However, for high-precision stamping or molding applications, it can be a limiting factor.

When to Choose a Different Press

If your application demands maximum rigidity and parallelism under extreme loads, a press with a more robust, enclosed structure may be necessary.

Presses like the H-frame or the 4-post press distribute forces more evenly across a closed frame, minimizing deflection and making them better suited for high-tonnage, precision-critical work.

Is a Frame Press Right for Your Application?

Choosing the right tool depends entirely on your specific goals. A frame press is a powerful and flexible machine, but its suitability hinges on the balance between versatility and precision.

- If your primary focus is general fabrication and repair: A C-frame press is an excellent choice due to its versatility for bending, straightening, and press-fitting a wide variety of parts.

- If your primary focus is medium-volume assembly: The controlled force and open access make it ideal for press-fitting bearings, bushings, and other components.

- If your primary focus is high-precision, high-tonnage stamping: You should consider the potential for frame deflection and evaluate whether a more rigid 4-post press would better serve your needs.

Ultimately, the frame press is an indispensable tool defined by its adaptability for countless forming and assembly tasks.

Summary Table:

| Application | Key Function | Ideal For |

|---|---|---|

| Assembly/Disassembly | Press-fitting bearings, bushings, pins | Workshops, production lines |

| Bending & Forming | Shaping sheet metal, bar stock | Metal fabrication shops |

| Straightening | Correcting warped or bent parts | Repair and maintenance |

| Stamping & Riveting | Creating impressions, installing rivets | Medium-volume manufacturing |

Need a reliable solution for your workshop's bending, pressing, or assembly tasks? KINTEK specializes in robust lab and workshop equipment, including hydraulic presses tailored for fabrication and R&D. Our experts can help you select the perfect press to enhance your productivity and precision. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the weakness of hydraulic press? Understand the Trade-offs of Power and Control

- What are the industrial applications of plate and frame filter press? A Guide to Efficient Solid-Liquid Separation

- What are the advantages of press forging in comparison to drop forging? Superior Control and Material Integrity

- What are the methods of infrared spectroscopy? A Guide to Solid, Liquid, and Gas Sample Prep

- What is role of KBr in IR-spectroscopy? Create Transparent Pellets for Accurate Solid Sample Analysis

- Which is the most common type of press used in industry? Hydraulic vs. Mechanical

- What size sample for XRF? The Key to Accurate Elemental Analysis

- What is the effect of heat generated in hydraulic system? Prevent Costly Damage and Downtime