At its core, a membrane filter press is an advanced dewatering machine used in wastewater treatment that adds a critical step to the standard filtration process. While a basic filter press separates solids from liquids by pumping slurry through filter cloths, a membrane press goes further by using flexible, inflatable membranes to physically squeeze the captured solids, forcing out significantly more water.

The crucial advantage of a membrane filter press is its ability to produce a much drier solid "cake" in less time. This directly translates to lower sludge disposal costs and higher operational efficiency for a treatment facility.

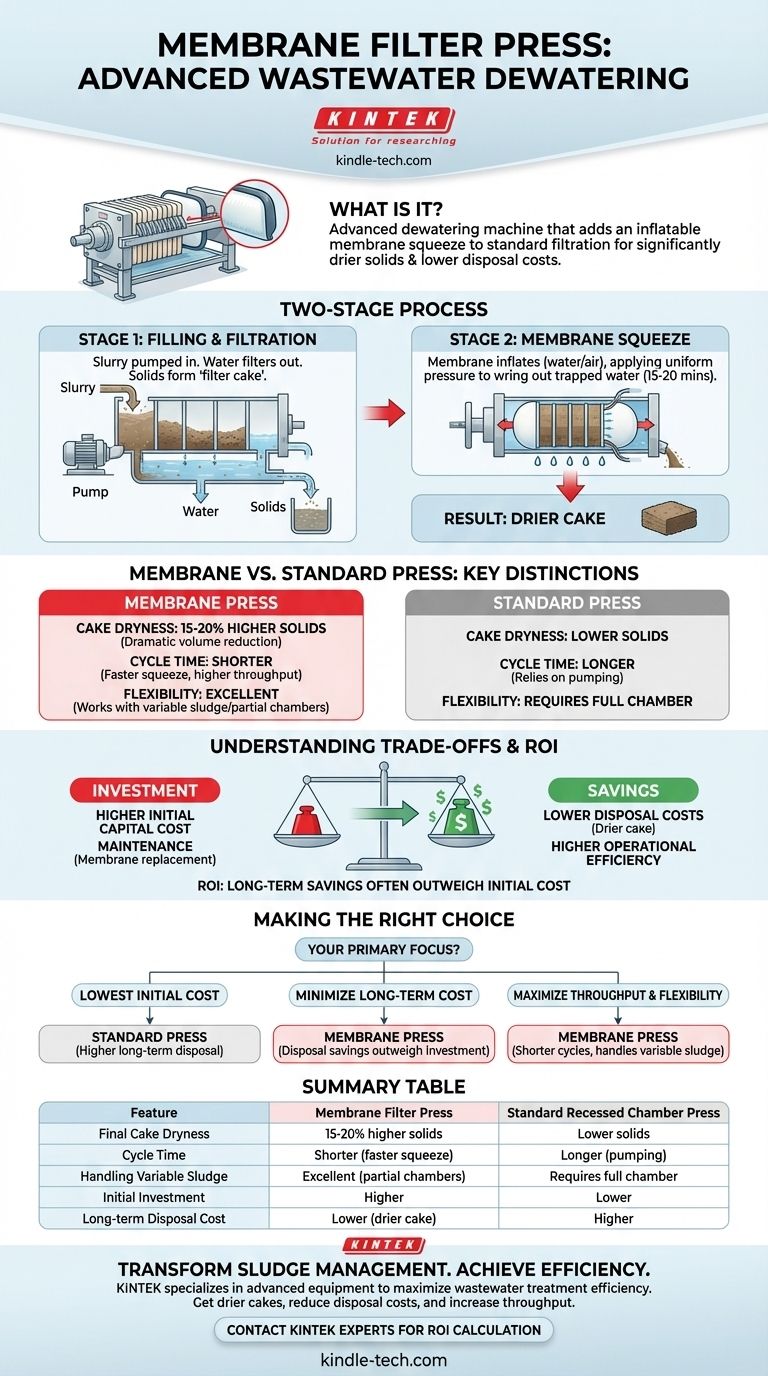

How a Membrane Filter Press Works: A Two-Stage Process

The operation is best understood as a sequence of two main stages: the standard filtration cycle followed by a unique compression cycle.

Stage 1: The Filling and Filtration Cycle

This initial stage is identical to that of a standard recessed chamber filter press. Slurry from the wastewater treatment process is pumped under pressure into a series of empty chambers lined with filter cloth.

The liquid (filtrate) passes through the cloth and is channeled away as clean water, while the solid particles are trapped and begin to build up on the cloth surface. Pumping continues until the chambers are filled with these semi-dry solids, forming what is known as a "filter cake."

Stage 2: The Membrane Squeeze Cycle

This is the key differentiating step. Once the pump feed stops, the flexible membranes installed behind the filter cloths are inflated with either water or compressed air.

This inflation exerts powerful, uniform pressure directly onto the entire surface of the filter cake. The mechanical squeeze physically wrings out additional water trapped within the cake, which then exits through the same filtrate ports. This cycle is remarkably fast, often lasting only 15-20 minutes.

The Result: Drier, Lighter Cake

After the squeeze cycle, the pressure is released, the press plates are separated, and the resulting filter cakes—now significantly drier and more compact—are discharged for disposal.

Membrane vs. Standard Press: Key Distinctions

While both technologies dewater sludge, the addition of the membrane squeeze creates significant operational differences.

Cake Dryness and Volume Reduction

This is the primary benefit. A membrane press can achieve a solids content that is 15-20% higher than a conventional press. This seemingly small percentage results in a dramatic reduction in the final cake's weight and volume.

Cycle Time Efficiency

Because the final dewatering is achieved through a rapid mechanical squeeze rather than extended, high-pressure pumping, overall cycle times are much shorter. A shorter cycle means more batches can be processed per day, increasing the plant's overall throughput capacity.

Performance with Variable Sludge

Membrane presses excel where sludge consistency varies. A standard press requires a full chamber to form a good cake, but a membrane press can effectively squeeze a partially filled chamber, ensuring consistent cake dryness even with fluctuating feed solids.

Understanding the Trade-offs

The superior performance of a membrane press comes with certain considerations.

Higher Initial Investment

A membrane filter press has a higher upfront capital cost compared to a standard recessed chamber press due to the added complexity of the membranes and their inflation system.

Maintenance Considerations

The membranes are robust but are considered a wear component. They will eventually need to be replaced, which represents a long-term operational expense not present in standard presses.

The Payback Calculation

The decision almost always comes down to a return on investment (ROI) calculation. The higher initial cost is weighed against the substantial and immediate savings on sludge hauling and disposal fees, which are typically charged by weight.

Making the Right Choice for Your Plant

Choosing the correct dewatering technology depends entirely on your facility's operational priorities and economic drivers.

- If your primary focus is the lowest possible initial capital cost: A standard recessed chamber press might be considered, but be prepared for higher long-term disposal expenses.

- If your primary focus is minimizing long-term operational costs: The membrane filter press is the clear winner, as the savings in disposal fees will typically outweigh the higher initial investment over time.

- If your primary focus is maximizing throughput and operational flexibility: The shorter cycle times and ability to handle variable sludge make the membrane press the superior technical choice.

Ultimately, investing in the right dewatering technology transforms sludge management from a costly liability into a streamlined, efficient, and controlled process.

Summary Table:

| Feature | Membrane Filter Press | Standard Recessed Chamber Press |

|---|---|---|

| Final Cake Dryness | 15-20% higher solids content | Lower solids content |

| Cycle Time | Shorter (faster squeeze cycle) | Longer (relies on pumping) |

| Handling Variable Sludge | Excellent (squeezes partial chambers) | Requires full chamber for optimal cake |

| Initial Investment | Higher | Lower |

| Long-term Disposal Cost | Lower (due to drier cake) | Higher |

Transform your sludge management from a costly liability into an efficient process. KINTEK specializes in advanced lab and industrial equipment, including membrane filter presses designed to maximize your wastewater treatment efficiency. Our solutions help you achieve drier cakes, reduce disposal costs, and increase throughput. Contact our experts today to calculate your ROI and find the perfect dewatering system for your facility!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy