A press furnace is a specialized industrial furnace that simultaneously applies both high temperature and significant mechanical pressure to a material. This dual action is performed within a highly controlled environment, often a vacuum or a specific inert gas atmosphere. The purpose is not simply to melt a material, but to sinter, densify, or bond it into a solid, high-integrity component.

The defining characteristic of a press furnace is its dual-function capability: applying both intense heat and mechanical force in a controlled environment. This unique combination is not just for melting, but for fundamentally changing a material's density and structure, fusing particles together into a solid, high-performance component.

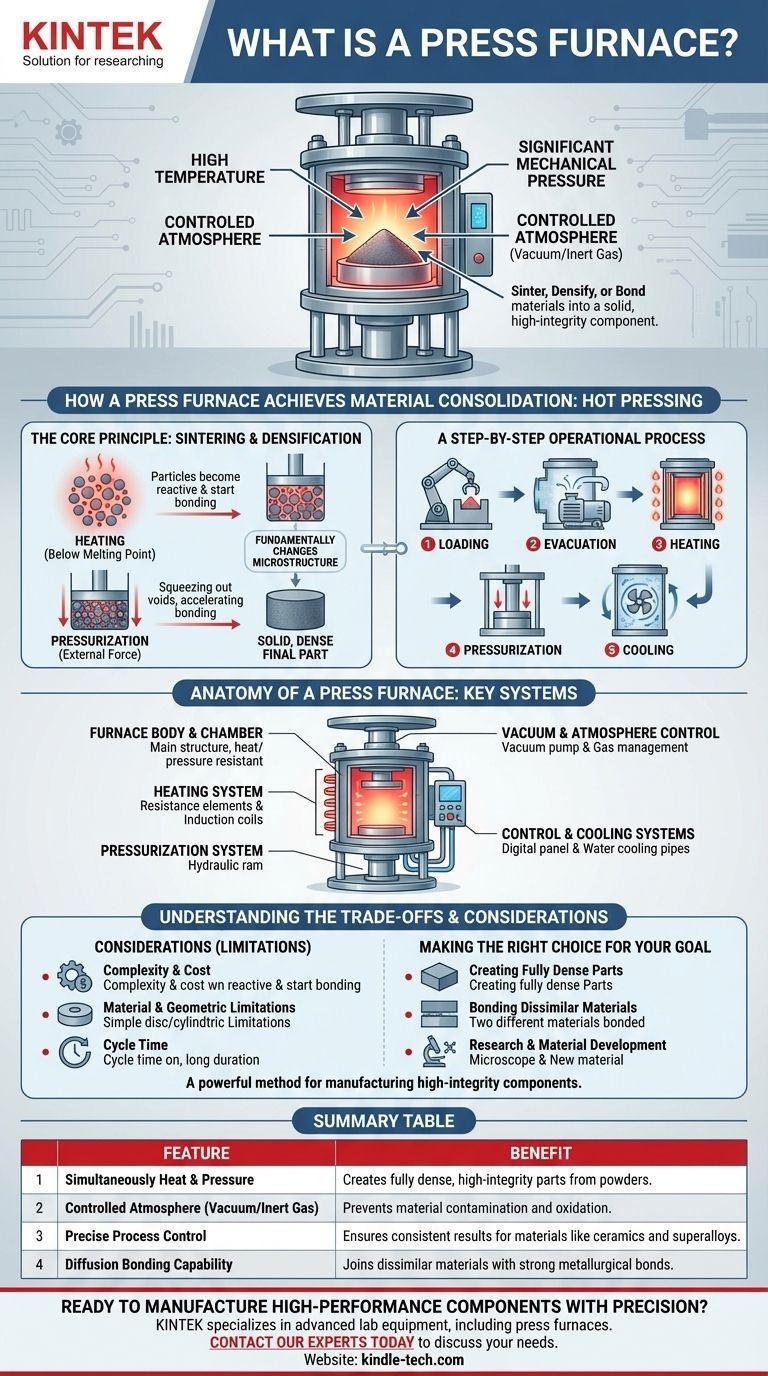

How a Press Furnace Achieves Material Consolidation

A press furnace operates on the principle of hot pressing, a process that fundamentally changes a material's microstructure. It is most commonly used to turn powders into fully dense solids.

The Core Principle: Sintering and Densification

The process begins by heating the material, typically a ceramic or metal powder, to a temperature below its melting point. This heat makes the individual particles more reactive and allows them to start bonding where they touch.

Simultaneously, the pressurization system applies an external force. This force compacts the particles, squeezing out the voids and pores between them and accelerating the bonding process. The result is a solid, dense final part.

A Step-by-Step Operational Process

While specific parameters vary, the general workflow of a hot press furnace follows a clear sequence:

- Loading: The raw material (e.g., ceramic powder in a mold) is placed inside the furnace chamber.

- Evacuation: The chamber is pumped down to create a vacuum, removing oxygen and other gases that could contaminate the material at high temperatures.

- Heating: The heating system raises the material to the target process temperature.

- Pressurization: The pressure system applies a pre-determined amount of force for a specific duration.

- Cooling: After the cycle is complete, the part is cooled in a controlled manner, often using a circulating inert gas, before being removed.

Anatomy of a Press Furnace: Key Systems

A press furnace is a complex machine integrating several critical systems to achieve precise control over the manufacturing environment.

The Furnace Body and Chamber

This is the main structural enclosure that contains the heating zone and the workpiece. It is designed to withstand extreme temperatures, high pressure, and deep vacuum conditions.

The Heating System

The heating system provides the thermal energy for the process. This is often achieved with electrical resistance heating elements positioned around the chamber for uniform heat. In some advanced furnaces, induction heating is used, where an electromagnetic field directly heats the conductive material or mold without heating the entire chamber.

The Pressurization System

This is the system that defines the "press" in a press furnace. It is typically a hydraulic or electro-mechanical ram that exerts a controlled, compressive force on the material inside the furnace.

The Vacuum and Atmosphere Control System

This system is responsible for creating the controlled environment. A powerful vacuum pump removes ambient air, while a gas management system can introduce specific inert gases like argon or nitrogen to protect the material from oxidation or to assist in rapid cooling.

The Control and Cooling Systems

A sophisticated control system manages and synchronizes all variables, including temperature ramp rates, pressure application, and vacuum levels. A water-cooling system circulates water through the furnace body to protect it from the intense internal heat and ensure operational safety.

Understanding the Trade-offs and Considerations

While powerful, press furnaces are specialized tools with specific limitations that are important to understand.

Complexity and Cost

These are highly complex and expensive pieces of equipment. The need to integrate high-temperature, high-pressure, and high-vacuum systems into a single machine drives up both the initial investment and ongoing maintenance costs.

Material and Geometric Limitations

Hot pressing is best suited for producing parts with relatively simple geometries, such as discs, blocks, or cylinders. The uniaxial (single-direction) nature of the pressing force makes it difficult to create complex, three-dimensional shapes with internal features.

Cycle Time

The process of creating a vacuum, slowly heating to temperature, holding for the required duration, and then carefully cooling down can take several hours. This makes hot pressing a relatively low-volume manufacturing process compared to methods like metal injection molding or casting.

Making the Right Choice for Your Goal

A press furnace is not a universal solution, but it is an indispensable tool for achieving specific material properties.

- If your primary focus is creating fully dense, high-performance parts: A press furnace is the ideal tool for achieving near-100% density in materials like advanced ceramics, superalloys, or metal matrix composites.

- If your primary focus is bonding dissimilar materials: The combination of heat and pressure makes the furnace highly effective for diffusion bonding, creating strong metallurgical joints between different metals or materials that cannot be welded.

- If your primary focus is research and material development: The precise control over temperature, pressure, and atmosphere makes it an invaluable instrument for developing new alloys and composite materials with unique properties.

Ultimately, a press furnace provides a powerful method for manufacturing high-integrity components that are impossible to create through heating or pressing alone.

Summary Table:

| Feature | Benefit |

|---|---|

| Simultaneous Heat & Pressure | Creates fully dense, high-integrity parts from powders. |

| Controlled Atmosphere (Vacuum/Inert Gas) | Prevents material contamination and oxidation. |

| Precise Process Control | Ensures consistent results for materials like ceramics and superalloys. |

| Diffusion Bonding Capability | Joins dissimilar materials with strong metallurgical bonds. |

Ready to manufacture high-performance components with precision?

KINTEK specializes in advanced lab equipment, including press furnaces, to meet your specific material development and production needs. Whether you are working with advanced ceramics, superalloys, or composites, our expertise ensures you achieve superior densification and material performance.

Contact our experts today to discuss how a KINTEK press furnace can enhance your laboratory's capabilities and drive your research or production forward.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Laboratory High Pressure Vacuum Tube Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- How does a vacuum hot-pressing furnace manufacture high-density NiCrAlY-Mo-Ag? Achieve 100% Densification

- What is the significance of the synchronous pressure in SiC-metal FGM? Bonding Excellence via Hot Pressing

- How does a vacuum hot press sintering furnace contribute to graphite/copper composites? Key Benefits & Mechanisms

- What is the critical function of hot pressing for TlBr semiconductors? Maximize Detector Precision & Crystal Density

- What are the typical operating pressures and temperatures for HIP? Optimize Your Material Density

- How does furnace temperature control affect Diamond/Al-Cu composites? Maximize Phase Control and Thermal Performance.

- What are the primary functions of a vacuum hot press? Master Nanostructured Copper Consolidation with High Density

- How does the uniaxial pressure applied by a vacuum hot press furnace affect the microstructure of B4C-based composites?