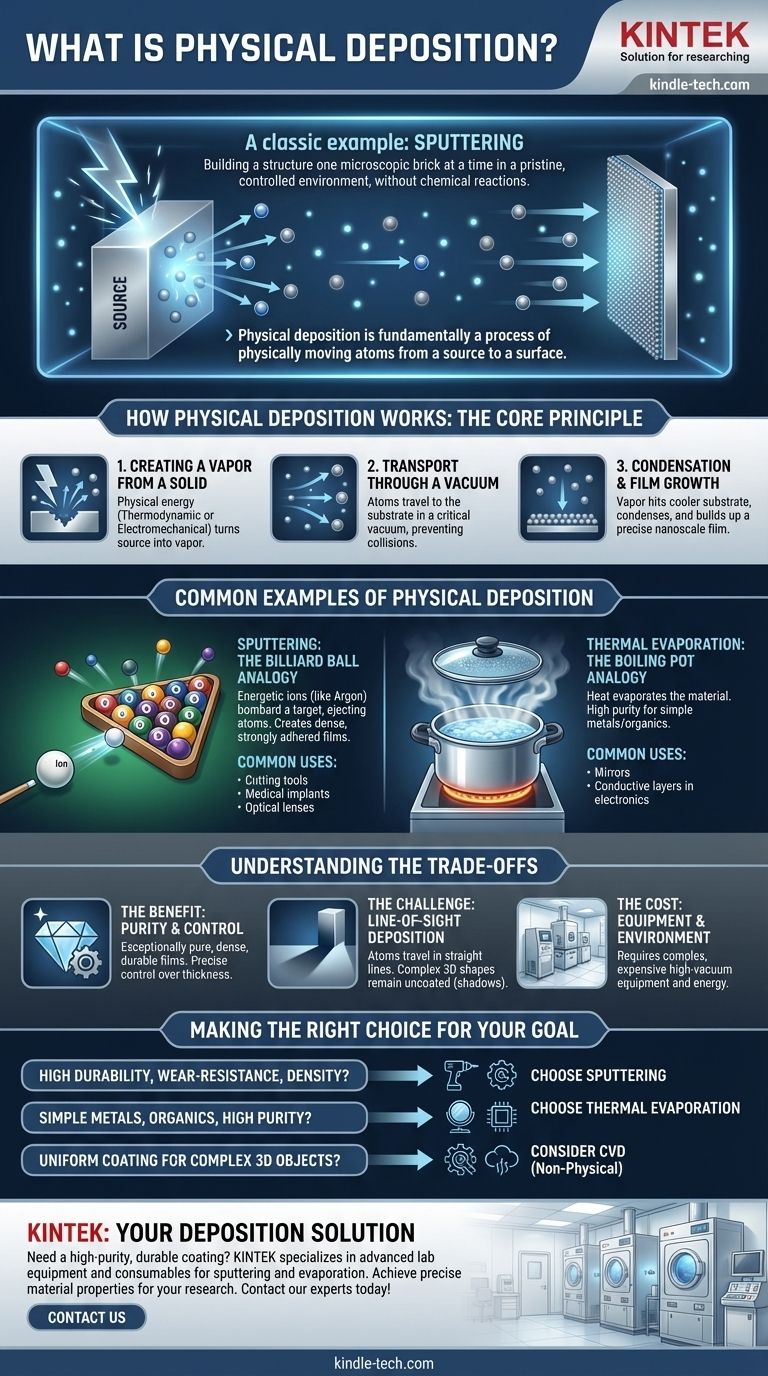

A classic example of physical deposition is a process called sputtering. In sputtering, a solid block of the desired coating material, known as the "target," is bombarded with high-energy ions inside a vacuum. This impact physically knocks atoms loose from the target, which then travel through the vacuum and deposit onto a substrate, building up a thin, uniform film atom by atom.

Physical deposition is fundamentally a process of physically moving atoms from a source to a surface without chemical reactions. Think of it less like painting and more like building a structure one microscopic brick at a time in a pristine, controlled environment.

How Physical Deposition Works: The Core Principle

To understand any example of physical deposition, you must first grasp the three essential steps that define the process. It is a highly controlled, line-of-sight technique performed in a vacuum.

Step 1: Creating a Vapor from a Solid

The entire process begins by turning a solid source material into a vapor of individual atoms or molecules. This is not done with chemistry, but with pure physical energy.

This energy can be thermodynamic (heating the material until it evaporates) or electromechanical (bombarding the material with energetic particles).

Step 2: Transport Through a Vacuum

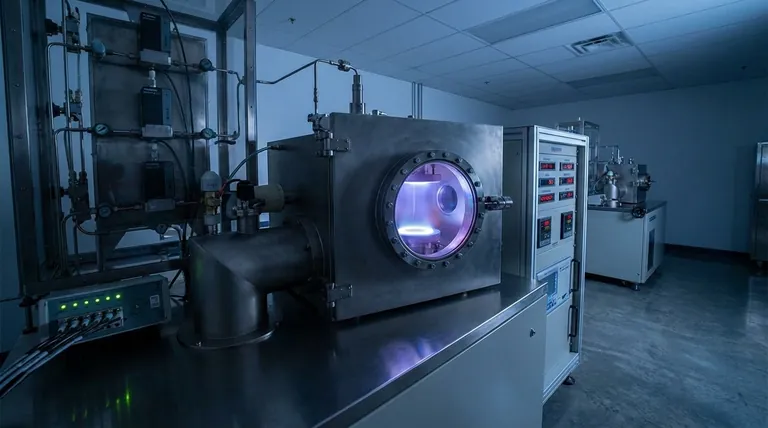

The newly freed atoms travel from the source to the object being coated (the "substrate"). This journey must happen in a vacuum chamber.

The vacuum is critical because it removes air and other particles. Without a vacuum, the coating atoms would collide with air molecules, scattering them and preventing a clean, dense film from forming.

Step 3: Condensation and Film Growth

When the vaporized atoms strike the cooler substrate, they rapidly lose their energy, condense back into a solid state, and stick to the surface.

This process continues, building up a thin film with a thickness that can be controlled with extreme precision, often on the scale of nanometers.

Common Examples of Physical Deposition

While the principle is the same, different methods use different ways to create the initial vapor. Sputtering and evaporation are two of the most common.

Sputtering: The Billiard Ball Analogy

Sputtering, our initial example, is a highly versatile technique. Imagine a tightly packed rack of billiard balls (the atoms of the target material).

You then fire a high-speed cue ball (an energetic ion, typically of a gas like Argon) into the rack. The impact ejects other balls from the rack in various directions. These ejected balls are the sputtered atoms that go on to form the coating.

Thermal Evaporation: The Boiling Pot Analogy

Thermal evaporation is a simpler method that uses heat. Imagine a pot of boiling water. The heat provides the energy for water molecules to escape the liquid and become steam (a vapor).

If you hold a cool lid over the pot, the steam will condense on it, forming a layer of water. In thermal evaporation, the "water" is a metal or other material heated in a vacuum, and the "lid" is the substrate receiving the coating.

Understanding the Trade-offs

Physical deposition is a powerful but specific tool. Its advantages are also tied to its limitations.

The Benefit: Purity and Control

Because the process occurs in a vacuum and involves no chemical reactions, the resulting films are exceptionally pure, dense, and durable. Engineers have precise control over the film's thickness and structure.

The Challenge: Line-of-Sight Deposition

The atoms travel in straight lines from the source to the substrate. Any area not in the direct line-of-sight of the source will be left uncoated, creating a "shadow." This makes coating complex, three-dimensional shapes very challenging.

The Cost: Equipment and Environment

Creating a high-vacuum environment and generating the energy needed for sputtering or evaporation requires complex and expensive equipment. It is not a casual or low-cost manufacturing process.

Making the Right Choice for Your Goal

Selecting a physical deposition method depends entirely on the desired properties of the final film and the material being used.

- If your primary focus is creating highly durable, wear-resistant, or dense films: Sputtering is often the superior choice for its ability to create strongly adhered coatings on materials like cutting tools, medical implants, and optical lenses.

- If your primary focus is depositing simple metals or organic compounds with high purity: Thermal evaporation can be a more straightforward and cost-effective method, commonly used for creating reflective layers on mirrors or conductive layers in electronics.

- If your primary focus is coating a complex 3D object uniformly: You may need to investigate non-physical methods like Chemical Vapor Deposition (CVD), which uses a chemical gas that can reach surfaces not in the line of sight.

Understanding these core principles empowers you to select the right deposition technique to achieve a specific material property.

Summary Table:

| Example | Core Principle | Key Advantage | Common Use Case |

|---|---|---|---|

| Sputtering | Bombarding a target with ions to eject atoms | Creates dense, strongly adhered films | Cutting tools, medical implants, optical lenses |

| Thermal Evaporation | Heating a material until it vaporizes | High purity for simple metals/organics | Mirrors, conductive layers in electronics |

Need a high-purity, durable coating for your lab equipment or research? The right physical deposition method is critical for achieving precise material properties. KINTEK specializes in advanced lab equipment and consumables for deposition processes, helping you select and implement the ideal solution for your specific application—whether it's sputtering for wear-resistant tools or evaporation for electronic components. Contact our experts today to discuss your project requirements and discover how we can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application