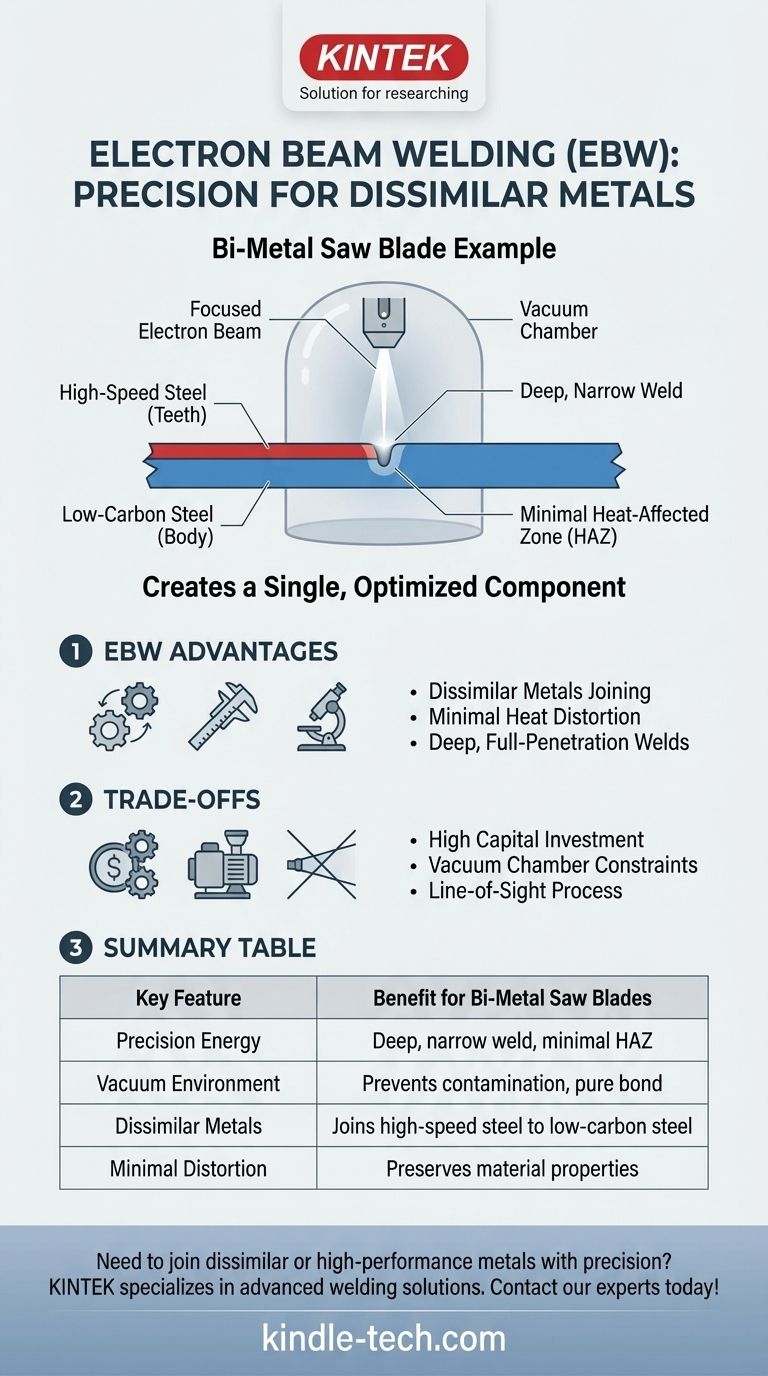

A classic example of electron beam welding is the mass production of bi-metal saw blades. This process joins a narrow strip of hard, high-speed steel for the cutting teeth to a flexible, low-carbon steel body for the main part of the blade. The result is a single, optimized component that leverages the best properties of two different materials.

Electron Beam Welding (EBW) is not just a joining method; it's a precision manufacturing process that enables the fusion of otherwise incompatible materials. The bi-metal saw blade example perfectly illustrates its core value: creating a single, superior component from two specialized metals.

Why Bi-Metal Saw Blades Depend on EBW

The bi-metal saw blade is a perfect case study because it presents a manufacturing challenge that conventional welding methods cannot easily solve. EBW provides a unique solution by fundamentally changing how energy is applied to the materials.

The Challenge of Dissimilar Metals

Joining high-speed steel to low-carbon steel is notoriously difficult. Their different thermal properties and melting points mean that traditional welding would create a wide, brittle, and weak joint, rendering the blade useless.

The Precision of the Electron Beam

EBW uses a highly focused beam of high-velocity electrons to deliver intense energy to a very small spot. This creates an extremely deep and narrow weld with a minimal heat-affected zone (HAZ). The surrounding material remains relatively cool, preserving its original properties.

The Benefit of a Vacuum

The entire process occurs within a vacuum chamber. This is critical because it prevents atmospheric gases like oxygen and nitrogen from contaminating the molten metal. This ensures a pure, strong, and defect-free bond, which is essential when joining dissimilar or reactive metals.

Understanding the Trade-offs of EBW

While powerful, Electron Beam Welding is a specialized process with significant operational considerations. It is not a universal replacement for other welding techniques.

High Capital Investment

EBW systems, which include the electron gun, high-voltage power supply, and vacuum chamber, are significantly more expensive than standard arc welding equipment. This makes the process best suited for high-value or mass-production applications where the cost can be justified.

The Vacuum Requirement

The need for a vacuum chamber introduces a time delay for pumping down the chamber before welding can begin. It also places a physical limit on the size of the parts that can be processed, which is dictated by the chamber dimensions.

Line-of-Sight Process

The electron beam travels in a straight line. It cannot weld around corners or reach obstructed areas, which places constraints on joint design and part geometry.

Making the Right Choice for Your Goal

Understanding when to specify EBW comes down to the unique demands of your application. It excels where other processes fall short.

- If your primary focus is joining dissimilar materials: EBW offers an unparalleled ability to create clean, strong welds between metals that are difficult or impossible to join with other methods.

- If your primary focus is minimizing heat distortion: The highly focused energy of EBW is ideal for delicate components or assemblies where maintaining tight dimensional tolerances after welding is critical.

- If your primary focus is achieving deep, narrow welds: EBW can produce weld depths that are far greater than its width, which is perfect for applications requiring strong, full-penetration joints with a single pass.

By understanding its specific strengths, you can leverage Electron Beam Welding to solve manufacturing challenges that are out of reach for conventional processes.

Summary Table:

| Key Feature | Benefit for Bi-Metal Saw Blades |

|---|---|

| Precision Energy | Creates a deep, narrow weld with a minimal heat-affected zone. |

| Vacuum Environment | Prevents contamination, ensuring a pure, strong bond. |

| Dissimilar Metals | Joins high-speed steel (teeth) to low-carbon steel (body) effectively. |

| Minimal Distortion | Preserves the properties of the surrounding material. |

Need to join dissimilar or high-performance metals with precision? KINTEK specializes in advanced welding and thermal processing solutions for laboratory and manufacturing needs. Our expertise in technologies like electron beam welding can help you create stronger, more reliable components. Contact our experts today to discuss how we can optimize your manufacturing process!

Visual Guide

Related Products

- Vacuum Cold Mounting Machine for Sample Preparation

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are the benefits of cold working metal? Achieve Superior Strength and Precision

- What are the examples of cold working metals? Key Processes for Stronger, Precision Parts

- Why use KBr to make the pellet? Achieve Clear, Accurate IR Spectroscopy Results

- What is a vacuum press machine? Harness Atmospheric Pressure for Perfect Lamination

- What can I make with a vacuum press? Unlock Perfect Laminating and Curved Forms