The primary benefit of cold working is a significant increase in a metal's strength and hardness through a process known as strain hardening. This process also yields a superior surface finish and tighter dimensional tolerances compared to methods involving heat.

Cold working fundamentally trades a metal's ductility for increased strength. By deforming the material below its recrystallization temperature, you are altering its internal structure to resist further deformation, making it stronger but more brittle.

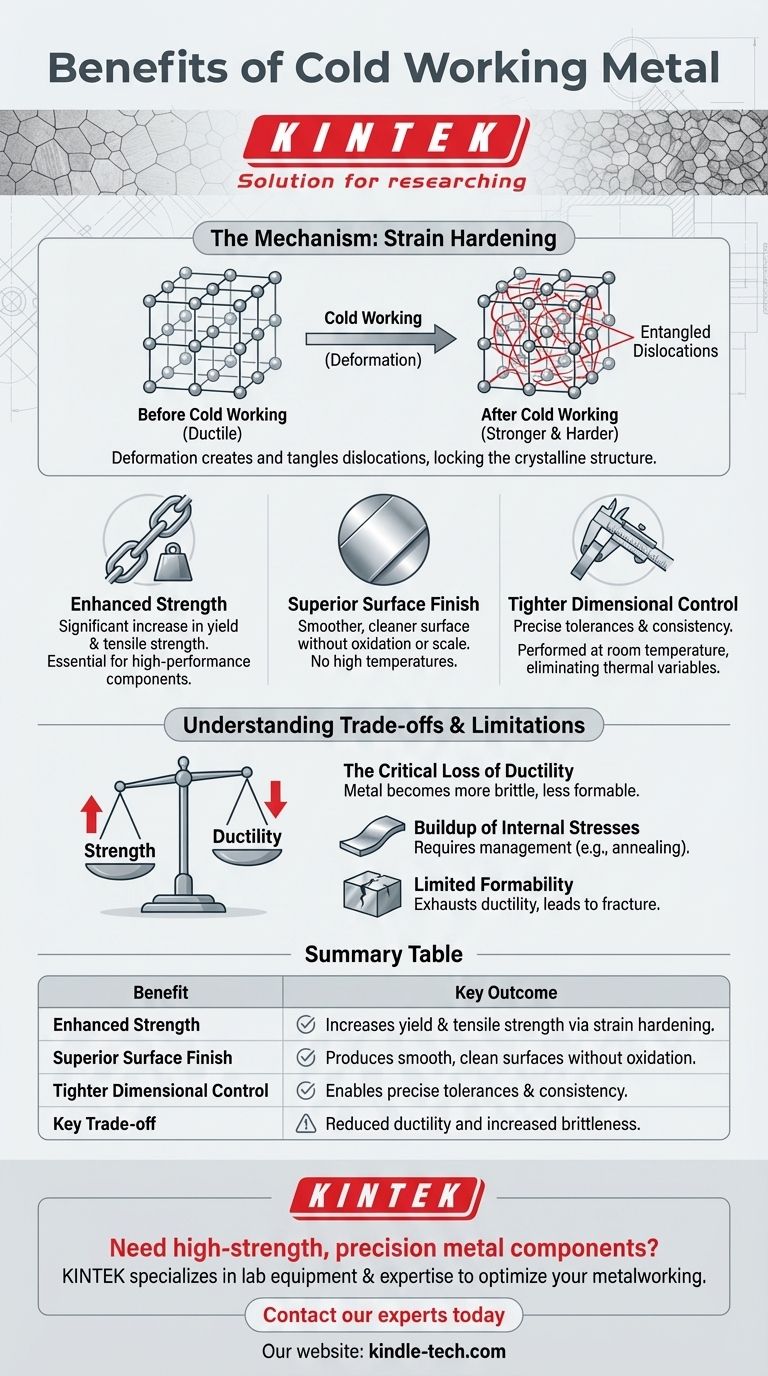

The Mechanism: How Cold Working Strengthens Metal

To understand the benefits, we must first look at what happens inside the metal at a microscopic level. The process intentionally manipulates the material's crystalline structure.

The Crystalline Structure

Metals are composed of microscopic crystals, or grains. Within these grains, atoms are arranged in a regular, repeating lattice.

When a metal is deformed, these planes of atoms slide past one another. This sliding is the basis of a metal's ability to change shape without breaking.

Creating and Entangling Dislocations

This sliding process is not perfect. It happens along microscopic imperfections in the crystal lattice called dislocations.

Cold working, such as rolling or drawing, forces the creation of a massive number of new dislocations. As they multiply, they begin to move and tangle with one another, like a snarled bundle of threads.

The Result: Strain Hardening

This entanglement makes it progressively more difficult for the atomic planes to slide. The tangled dislocations effectively lock the crystal structure in place.

This resistance to internal slip is what we observe on a macro level as increased tensile strength and hardness. The metal has been "strain hardened."

Key Benefits in Application

This internal change produces several desirable external properties that are critical for engineering and manufacturing.

Enhanced Mechanical Strength

The most significant benefit is the increase in yield strength and tensile strength. A cold-worked part can withstand higher loads before it begins to deform or fracture, making it essential for high-performance components.

Superior Surface Finish

Because cold working does not involve high temperatures, the metal is not subject to oxidation or scale formation. This results in a much smoother, cleaner, and more reflective surface finish straight from the process.

Tighter Dimensional Control

Hot working involves thermal expansion and contraction, which can make holding precise dimensions difficult. Cold working is performed at or near room temperature, eliminating these thermal variables and allowing for much tighter tolerances and greater part-to-part consistency.

Understanding the Trade-offs and Limitations

The benefits of cold working do not come without costs. Understanding these limitations is crucial for proper material selection and process design.

The Critical Loss of Ductility

The primary trade-off for increased strength is a significant reduction in ductility—the metal's ability to stretch or deform without fracturing. The same tangled dislocations that increase strength also prevent the material from bending or stretching, making it more brittle.

Buildup of Internal Stresses

The deformation process introduces significant internal residual stresses into the material. If not properly managed, these stresses can lead to warping over time or cause premature failure under certain load conditions. Post-processing steps like stress-relief annealing are sometimes required.

Limited Formability

You can only cold work a metal so much before it exhausts its ductility and fractures. For complex shapes or large deformations, the material must be processed in stages with intermediate annealing cycles to restore ductility.

Increased Power Requirement

Deforming metal at room temperature requires substantially more force and energy than deforming it at high temperatures when it is softer. This necessitates more powerful and robust machinery.

Making the Right Choice for Your Goal

The decision to use cold working, hot working, or a combination of both depends entirely on the final application and design priorities.

- If your primary focus is maximum strength and a precise finish: Cold working is the superior choice for components like high-strength bolts, wires, and precision shafts.

- If your primary focus is large-scale shape change and toughness: Hot working is necessary for initial fabrication of large parts like I-beams or engine blocks, as it allows for massive deformation without fracture.

- If you need to restore ductility after cold working: Annealing is the required heat treatment process to recrystallize the grain structure and relieve internal stress.

Understanding this fundamental trade-off between strength and ductility is the key to mastering material selection for any engineering application.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Enhanced Strength | Increases yield and tensile strength via strain hardening. |

| Superior Surface Finish | Produces smooth, clean surfaces without oxidation. |

| Tighter Dimensional Control | Enables precise tolerances and part-to-part consistency. |

| Key Trade-off | Reduced ductility and increased brittleness. |

Need high-strength, precision metal components for your lab or production line?

Cold working is a powerful process to enhance the mechanical properties of your materials, but selecting the right technique is critical. KINTEK specializes in providing the lab equipment and expertise needed to optimize your metalworking processes. Whether you're developing new alloys or manufacturing precision parts, our solutions help you achieve superior strength and dimensional accuracy.

Let's discuss how we can support your project: Contact our experts today to explore the right cold working solutions for your specific laboratory and manufacturing needs.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Vacuum Cold Mounting Machine for Sample Preparation

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- How is isostatic pressing distinguished from conventional pressing? Unlock Superior Uniformity and Density

- What is the isostatic pressing method? Achieve Uniform Density and Superior Material Performance

- What is cold isostatic pressing? Achieve Uniform Density for Complex Parts

- What is isostatic pressing of ceramics? Achieve Uniform Density and Complex Shapes

- What is the meaning of isostatic pressing? Achieve Uniform Density in Complex Parts

- What is isostatic pressing of polymers? Achieve Superior Uniform Density for High-Performance Parts

- What are the two types of presses? CIP vs. HIP for Advanced Materials Manufacturing

- What is the pressure for isostatic pressing? Unlock the Key to Uniform Material Densification