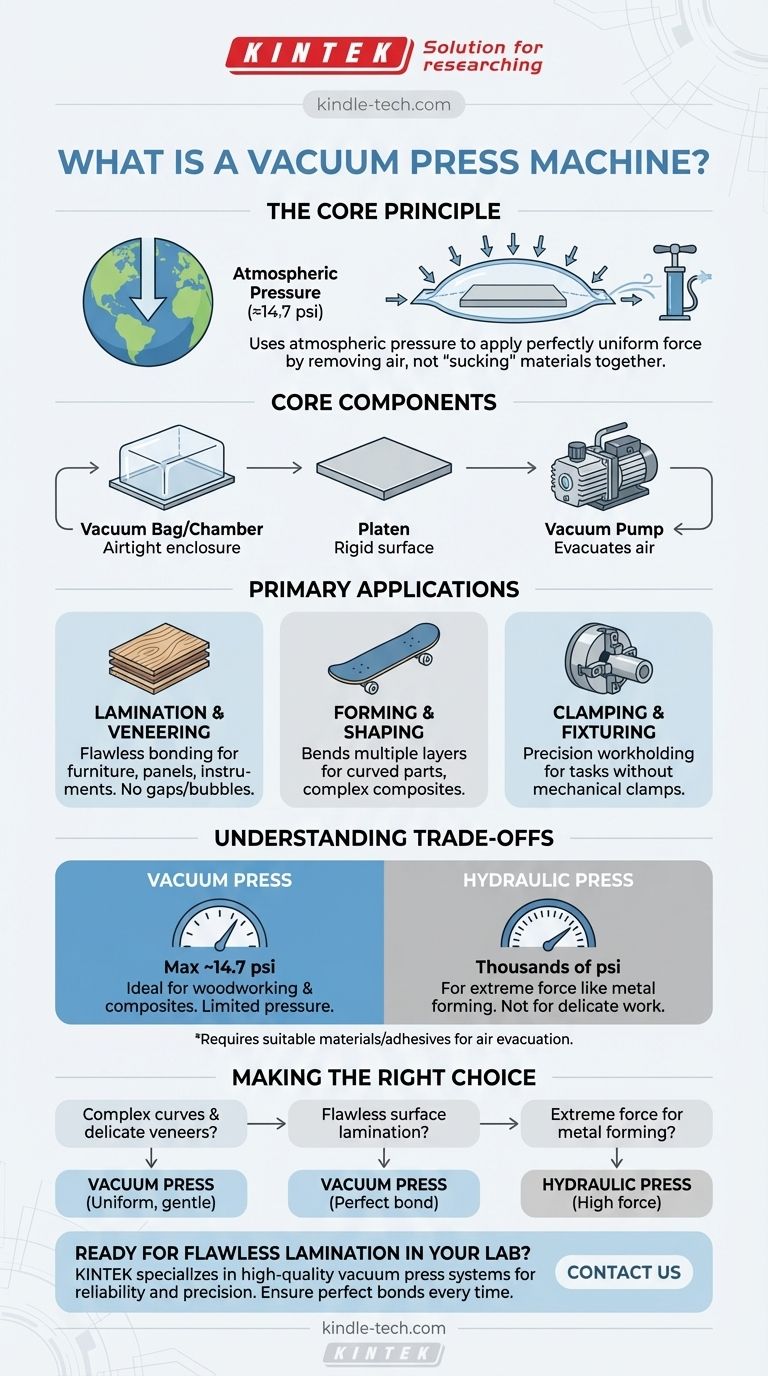

In essence, a vacuum press machine is a device that uses atmospheric pressure to laminate, veneer, or form materials with perfectly uniform force. It achieves this by removing the air from a sealed bag or chamber containing the workpiece, allowing the weight of the Earth's atmosphere to press down evenly across the entire surface.

The critical concept to understand is that a vacuum press doesn't "suck" materials together. Instead, it removes the air from one side of a workpiece, letting the immense, consistent pressure of the surrounding atmosphere do the work of a perfectly contoured clamp.

How a Vacuum Press Actually Works

To grasp the function of a vacuum press, you must first understand the fundamental principle it leverages. It's not about creating a powerful force, but about removing an opposing one.

The Principle of Atmospheric Pressure

At sea level, the air around us exerts pressure in all directions, approximately 14.7 pounds per square inch (psi). A vacuum press places a workpiece (e.g., layers of wood veneer and glue) into a vinyl or silicone bag and seals it.

A pump then removes the air from inside the bag, creating a vacuum. With no air pressure inside the bag pushing out, the full atmospheric pressure from the outside pushes in, applying a consistent and powerful clamping force across every square inch of the object's surface.

The Core Components

A typical system consists of three main parts:

- A Vacuum Bag or Chamber: This is the airtight enclosure that holds the workpiece.

- A Platen: The flat, rigid surface on which the project is assembled before being placed in the bag.

- A Vacuum Pump: This is the engine of the system, responsible for evacuating the air from the sealed bag.

Primary Applications of Vacuum Pressing

The ability to apply perfectly even pressure makes this technology incredibly versatile, far beyond simple lamination.

Lamination and Veneering

This is the most common use. The press ensures a flawless bond between a substrate and a surface material, such as wood veneer, without gaps or air bubbles. This is essential for creating high-quality panel furniture, decorative materials, and musical instruments like guitars and pianos.

Forming and Shaping

Because atmospheric pressure conforms to any shape, a vacuum press is ideal for creating curved components. It's used to bend multiple layers of wood for skateboard decks, fabricate curved stairway parts, or form complex composite materials like carbon fiber dashboards.

Clamping and Fixturing

A vacuum press can also function as a workholding device. By placing a part on a specialized vacuum chuck, it can be held firmly in place for precision tasks like template routing without the need for mechanical clamps that can get in the way or mar the surface.

Understanding the Trade-offs

While powerful, a vacuum press is a specific tool with its own set of limitations that are important to recognize.

Pressure Limitations

The maximum pressure a vacuum press can achieve is limited to the ambient atmospheric pressure—around 14.7 psi. While this is more than enough for woodworking and composites, it is significantly less than a hydraulic press, which uses liquid pressure to generate forces many thousands of times greater for applications like forging metal.

Material and Adhesive Choice

The process works best with materials and adhesives that allow air to be fully evacuated. Some glues, known as special hot-pressing glues, are specifically formulated to cure under the heat and pressure applied within some advanced press systems.

Process Suitability

A vacuum press is distinct from other industrial vacuum processes. For example, vacuum sintering is a high-temperature furnace process used to fuse powdered materials into a solid mass, which is fundamentally different from the bonding and forming tasks of a vacuum press.

Making the Right Choice for Your Goal

Selecting the correct pressing technology depends entirely on the forces and precision your project requires.

- If your primary focus is on complex curves and delicate veneers: A vacuum press is the ideal choice, offering uniform pressure that won't damage intricate work.

- If your primary focus is on flawless surface lamination: The technology provides a perfect bond for furniture, cabinetry, and architectural panels.

- If your primary focus is applying extreme force for metal forming or compaction: You require a hydraulic press, as atmospheric pressure will be insufficient for the task.

Ultimately, a vacuum press harnesses a fundamental force of nature to achieve precision and quality that is difficult to replicate with any other method.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Uses atmospheric pressure (14.7 psi) to apply uniform force by creating a vacuum. |

| Key Components | Vacuum bag/chamber, platen, and vacuum pump. |

| Primary Applications | Lamination, veneering, forming curved parts, and workholding. |

| Pressure Limitation | Max ~14.7 psi; suitable for woodworking/composites, not for heavy metal forming. |

Ready to achieve flawless lamination and precise material forming in your lab?

At KINTEK, we specialize in high-quality lab equipment, including vacuum press systems designed for reliability and precision. Whether you're working with wood veneers, composites, or other materials, our solutions help you eliminate air bubbles and ensure perfect bonds every time.

Contact us today using the form below to discuss how a KINTEK vacuum press can enhance your laboratory's capabilities and streamline your production process.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why is a laboratory hydraulic press necessary for Al-Fe-Ni alloy powder? Achieve Optimal Preform Density

- What is the purpose of using a laboratory hydraulic press for Al-LLZ powder? Achieve High-Density Green Bodies

- What is the purpose of using a laboratory hydraulic press for pre-pressure? Enhance Sintering Precision & Density

- What are the risks of a hydraulic press? Essential Safety and Operational Insights

- What are the maintenance required for the hydraulic system? A Proactive Guide to Prevent Costly Failures

- Who would use a hydraulic press? Mastering Controlled Force for Shaping, Compacting, and Testing

- What PSI should a hydraulic press be? The Answer Lies in Tonnage, Not Just Pressure

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis