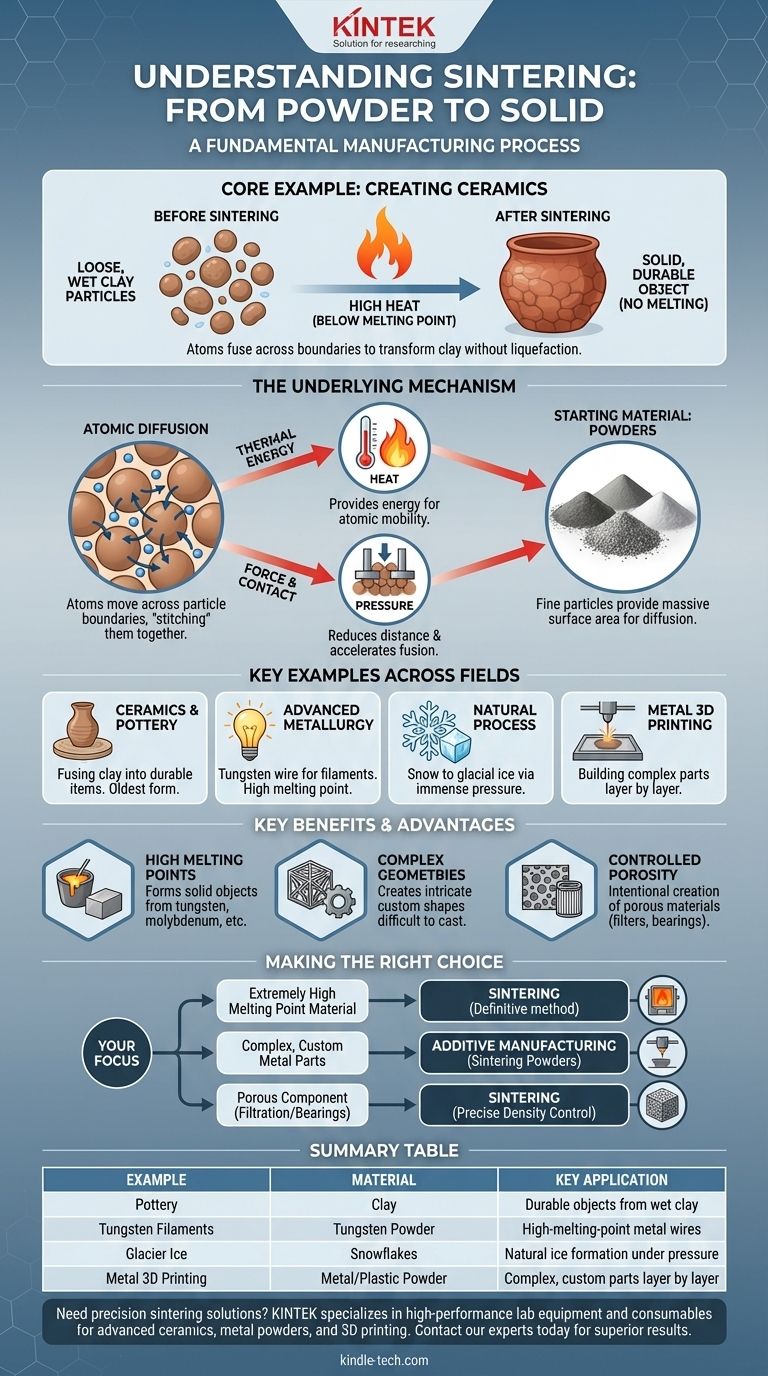

One of the most common examples of sintering is the creation of ceramics. When clay is fired in a kiln, the individual clay particles are heated to a high temperature, causing their atoms to fuse together across their boundaries. This process transforms the loose, wet clay into a single, solid, and durable object without ever melting the material into a liquid state.

Sintering is a fundamental manufacturing process that uses heat and/or pressure to fuse small particles into a solid mass. The key principle is that this transformation occurs below the material's melting point, relying on atomic diffusion to create a single, cohesive piece.

What is Sintering at a Deeper Level?

To truly grasp the concept, it's essential to understand the underlying mechanism that makes sintering possible for materials ranging from ancient pottery to modern jet engine components.

The Core Mechanism: Atomic Diffusion

Sintering works by encouraging atoms from individual particles to move and migrate across the boundaries where the particles touch. This atomic movement effectively "stitches" the particles together on a microscopic level.

The process bonds adjacent powder particle surfaces, gradually eliminating the empty spaces between them and increasing the density of the final object.

The Role of Heat and Pressure

Heat provides the thermal energy necessary to make the atoms mobile enough to diffuse across particle boundaries.

Pressure serves a complementary role by forcing the particles into close contact, which reduces the distance atoms need to travel and accelerates the fusion process. Some forms of sintering rely almost entirely on pressure, while most industrial applications use a combination of both.

The Starting Material: Powders

The process almost always begins with a material in a powdered form. This includes metals, ceramics, plastics, and other materials.

The fine particles provide a massive amount of surface area, which is critical for promoting the atomic diffusion that lies at the heart of the sintering process.

Key Examples Across Different Fields

While ceramics are a classic example, sintering is a versatile process with applications in nature, history, and cutting-edge technology.

Manufacturing: Ceramics and Pottery

This is the oldest form of sintering, dating back thousands of years. The firing process integrates discrete blobs of wet clay into a single, durable item by fusing the particles together.

Advanced Metallurgy: Tungsten Filaments

Sintering became a critical industrial process in 1909 for producing ductile tungsten wire for light bulb filaments. Tungsten's extremely high melting point makes it nearly impossible to melt and cast, so sintering powdered tungsten was the breakthrough solution.

A Natural Process: Snow to Glaciers

A simple, pressure-driven example of sintering occurs in nature. The immense pressure at the bottom of a snowpack compacts snowflakes, forcing their crystalline boundaries to fuse and eventually form solid glacial ice. Pressing loose snow into a hard snowball is a small-scale version of this same effect.

Modern Technology: Metal 3D Printing

Many forms of additive manufacturing use sintering. A machine lays down a thin layer of metal or plastic powder, and a laser or other heat source selectively sinters the particles to form a solid layer. This process is repeated layer by layer to build a complex, three-dimensional object.

Understanding the Key Benefits

Sintering is not just an alternative to melting and casting; it offers unique advantages that make it the only viable option for certain applications.

The Primary Advantage: High Melting Points

The most significant benefit of sintering is its ability to create solid objects from materials with exceptionally high melting points, such as tungsten and molybdenum. Melting these materials is often impractical or prohibitively expensive.

Creating Complex Geometries

Paired with technologies like 3D printing, sintering allows for the creation of intricate custom shapes that would be difficult or impossible to produce with traditional casting or machining methods.

Controlling Material Porosity

Because sintering starts with discrete particles, the final density can be controlled. This allows for the intentional creation of porous materials, which are essential for products like filters and self-lubricating bearings.

Making the Right Choice for Your Goal

Understanding when to leverage sintering is key to solving specific engineering and manufacturing challenges.

- If your primary focus is shaping a material with an extremely high melting point: Sintering is the definitive and often only practical method to form a solid part.

- If your primary focus is producing complex, custom metal parts: Additive manufacturing techniques that rely on sintering powders are the leading solution.

- If your primary focus is creating a porous component for filtration or bearings: The sintering process provides precise control over the final density and porosity of the material.

Ultimately, sintering is a powerful and fundamental process for transforming powders into solid objects without the need for liquefaction.

Summary Table:

| Sintering Example | Material Used | Key Application |

|---|---|---|

| Pottery & Ceramics | Clay | Creating durable, solid objects from wet clay |

| Tungsten Filaments | Tungsten Powder | Manufacturing high-melting-point metal wires |

| Snow to Glacier Ice | Snowflakes | Natural formation of solid ice under pressure |

| Metal 3D Printing | Metal/Plastic Powder | Building complex, custom parts layer by layer |

Need precision sintering solutions for your lab? KINTEK specializes in high-performance lab equipment and consumables for sintering applications. Whether you're working with advanced ceramics, metal powders, or custom 3D printing materials, our solutions deliver precise temperature control and consistent results. Contact our experts today to discuss how we can enhance your sintering processes and help you achieve superior material performance.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing

- Do you quench before tempering? Master the Essential Sequence for Strong, Durable Steel

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- How does furnace cooling occur in the heat treatment process? A Guide to Controlled Slow Cooling

- Why are ceramics sintered? Transform Powder into High-Performance Solid Components

- Why are metal envelopes or containers required for HIP? Achieve 100% Density in Alloy Powder Processing

- How does the degassing step in a vacuum oven influence the quality of molded F-LSR components? Enhance Material Strength

- What are the benefits of a heat treatment furnace? Achieve Precise Control Over Material Properties