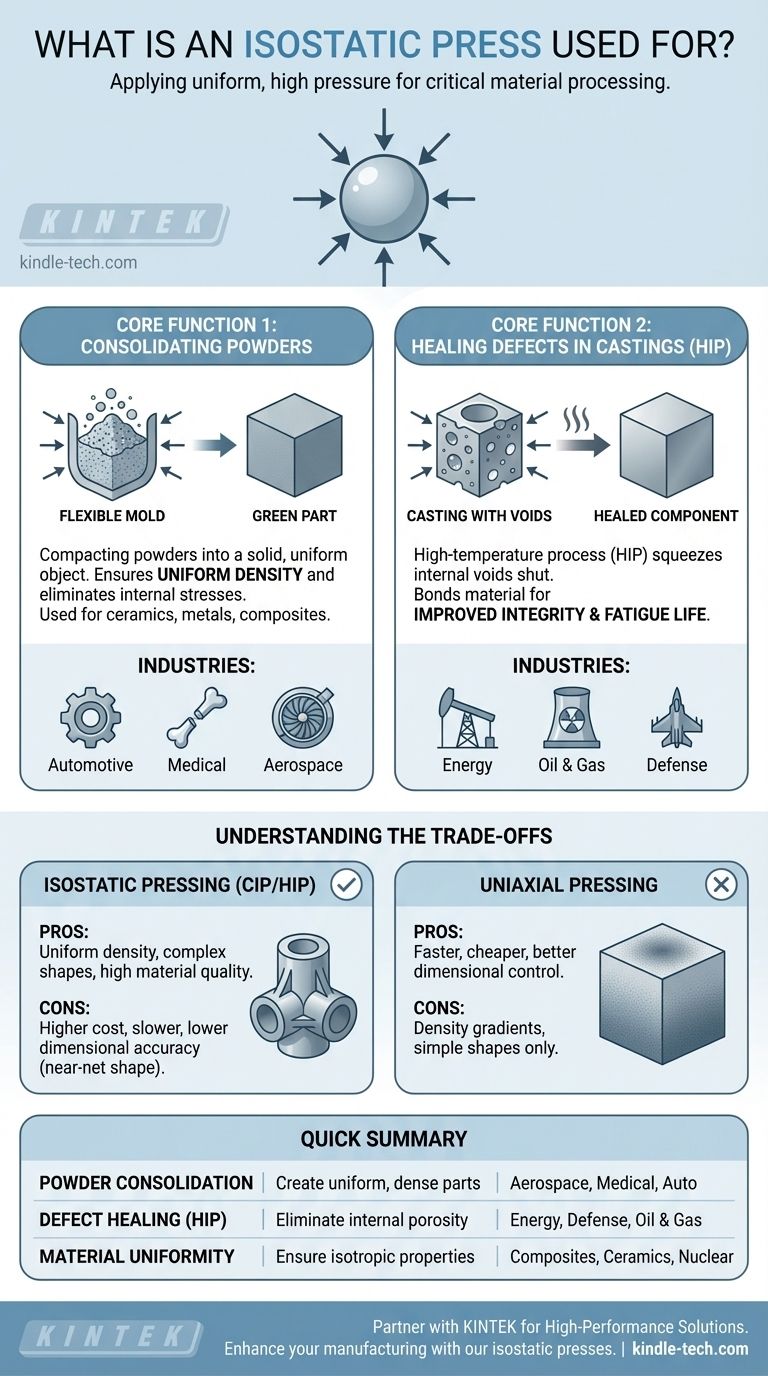

At its core, an isostatic press is used for two primary functions: consolidating powders into a solid mass and healing internal defects in castings. This process applies uniform, high pressure to a workpiece from all directions simultaneously, making it indispensable for manufacturing critical components in industries ranging from aerospace and medical to energy and food processing.

Isostatic pressing subjects a component to uniform pressure, similar to the pressure experienced deep in the ocean. This unique capability is why it's chosen to create highly uniform, dense parts from powders or to eliminate porosity in castings—problems that simpler, directional pressing methods cannot solve as effectively.

The Two Core Functions of Isostatic Pressing

To understand its applications, you must first grasp the two fundamental problems it solves. Nearly every use case falls into one of these two categories.

Function 1: Consolidating Powders

The most common use of isostatic pressing is to compact powders into a solid, uniform object. This initial object is often called a "green" part, which then undergoes further processing like sintering or machining.

The key benefit here is uniform density. Unlike a standard (uniaxial) press that applies force from only one or two directions, isostatic pressure compacts the powder evenly from all sides. This prevents density variations and internal stresses, which are critical for high-performance materials.

This technique is used for a vast range of powders, including ceramics, metals, plastics, composites, and even food products.

Function 2: Healing Defects in Castings

Isostatic pressing, specifically a high-temperature variant known as Hot Isostatic Pressing (HIP), is also used as a post-processing step for metal castings.

Castings can have microscopic internal voids or pores created during the solidification process. These defects can lead to cracks and premature failure under stress.

By subjecting the casting to immense pressure at elevated temperatures, the HIP process effectively squeezes these internal voids shut, bonding the material back together on an atomic level. This significantly improves the mechanical properties, fatigue life, and reliability of critical cast components.

Where This Technology Is Applied

The principle of applying uniform pressure has made isostatic pressing essential across numerous advanced industries.

Advanced Ceramics & Composites

Many advanced ceramics and composites are manufactured from powders. Isostatic pressing is used to form components for the aerospace, automotive, and defense industries. Applications include high-strength insulators, isotropic graphite, and parts that must withstand extreme conditions.

High-Performance Metals

In powder metallurgy, isostatic pressing is used to create parts from tool steel, refractory metals, and cemented carbides. It is also essential for manufacturing high-performance components for the oil and gas industry, wear-resistant tools, and metal forming tools.

Medical and Specialized Applications

The ability to create uniform, reliable parts makes this technology vital for sensitive applications. It is used to manufacture medical devices and implants like artificial bones, where material integrity is non-negotiable. Other specialized uses include consolidating nuclear fuel, processing chemicals, and even forming certain food products.

Understanding the Trade-offs

While powerful, isostatic pressing is not the solution for every manufacturing challenge. Understanding its limitations is key to using it appropriately.

The Challenge of Dimensional Accuracy

Cold Isostatic Pressing (CIP) excels at creating uniform density but often struggles with tight dimensional tolerances. The flexible molds used in the process do not provide the same precision as a rigid die.

Therefore, parts made via CIP are often produced as "near-net shapes" that require final machining to achieve precise dimensions. The goal of CIP is material quality first, not final shape precision.

Uniaxial vs. Isostatic Pressing

The primary alternative is uniaxial pressing, where a part is stamped in a rigid die. This method is faster, cheaper, and offers better dimensional control for simple shapes.

However, uniaxial pressing creates density gradients—the material closer to the punch is denser than the material in the middle. Isostatic pressing is chosen when the elimination of these gradients is more important than raw production speed or initial cost.

Complexity and Cost

Isostatic press systems are significantly more complex and expensive than their uniaxial counterparts. The need for high-pressure containment vessels and sophisticated control systems means this technology is typically reserved for applications where the performance benefits justify the investment.

Making the Right Choice for Your Goal

Deciding whether to use isostatic pressing depends entirely on your end goal and material requirements.

- If your primary focus is creating complex shapes from powder with maximum density uniformity: Isostatic pressing is the ideal choice, especially for materials that are difficult to process otherwise.

- If your primary focus is improving the mechanical properties of a critical metal casting: Hot Isostatic Pressing (HIP) is an essential post-processing step to eliminate internal porosity and enhance fatigue life.

- If your primary focus is high-volume production of simple shapes where cost is the main driver: A traditional uniaxial press is likely a more economical and faster solution.

Understanding the principle of uniform pressure is the key to deciding when to leverage the unique advantages of isostatic pressing.

Summary Table:

| Function | Primary Use | Key Industries |

|---|---|---|

| Powder Consolidation | Create uniform, dense parts from powders | Aerospace, Automotive, Medical |

| Defect Healing (HIP) | Eliminate internal porosity in castings | Energy, Oil & Gas, Defense |

| Material Uniformity | Ensure isotropic properties in advanced materials | Composites, Ceramics, Nuclear |

Need to create high-performance, reliable parts? KINTEK specializes in lab equipment and consumables, including isostatic pressing solutions for your laboratory. Whether you're consolidating advanced ceramics or healing critical metal castings, our expertise ensures you achieve maximum material density and integrity. Contact our experts today to discuss how our isostatic presses can enhance your manufacturing process and deliver superior results for your specific application.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What are the advantages and limitations of hot isostatic pressing? Achieve Ultimate Material Integrity