In essence, Chemical Vapor Deposition (CVD) for nanoparticle synthesis is a process that builds nanostructures from the ground up using chemical reactions in a gas phase. Gaseous precursor molecules are introduced into a reaction chamber where they decompose and react on a heated substrate, depositing a solid material atom by atom to form highly pure and precisely structured nanomaterials like nanotubes or graphene sheets.

The core principle of CVD is transforming gaseous chemicals into a solid, high-purity nanomaterial. It's not about carving down a larger material, but rather meticulously constructing the desired structure molecule by molecule, which is why it is a leading method for high-performance applications.

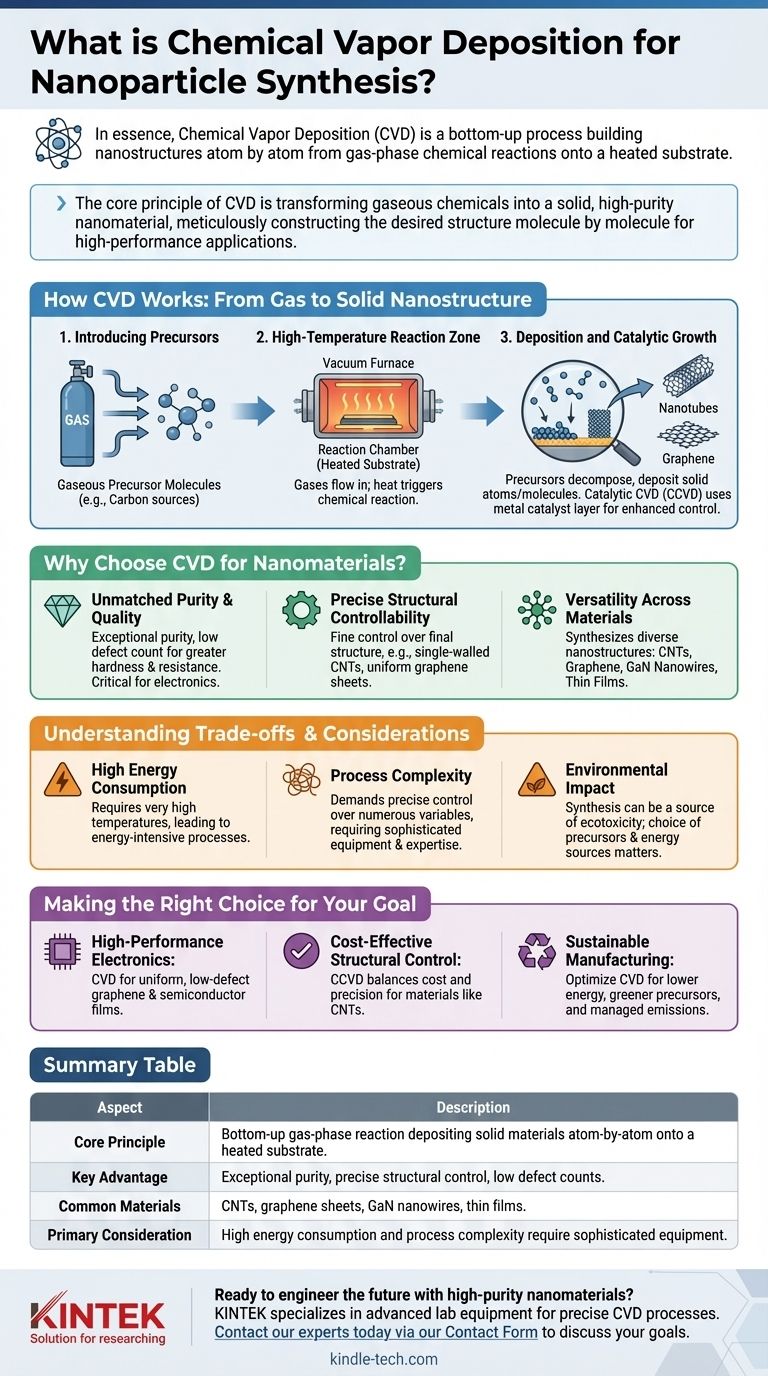

How CVD Works: From Gas to Solid Nanostructure

CVD is fundamentally a material deposition process. It involves a series of well-controlled steps to convert volatile precursors into a solid product on a surface.

Introducing the Precursors

The process begins with one or more gaseous precursor materials. These are chemical compounds that contain the elements you want to deposit, such as carbon for making graphene or carbon nanotubes.

The High-Temperature Reaction Zone

These gases flow into a reaction chamber, often a vacuum furnace, containing a prepared surface called a substrate. The chamber is heated to a specific, high temperature which provides the energy needed to trigger a chemical reaction.

Deposition and Catalytic Growth

Once inside the hot chamber, the precursor gases decompose and react. The resulting solid atoms or molecules then deposit onto the substrate, gradually building up the desired nanomaterial.

For many nanostructures, like carbon nanotubes, this process is enhanced by a catalyst. This variation, called Catalytic CVD (CCVD), uses a layer of metal catalyst nanoparticles to guide and control the growth, offering superior structural control.

Why Choose CVD for Nanomaterials?

CVD is not just one of many methods; it is often the preferred choice for applications where material quality is paramount. Its value comes from several distinct advantages.

Unmatched Purity and Quality

Compared to other coating methods, CVD produces materials with exceptional purity and a low defect count. This results in greater hardness and resistance to damage, which is critical for advanced electronics and durable coatings.

Precise Structural Controllability

The nature of the bottom-up CVD process allows for fine control over the structure of the final product. This is essential in nanotechnology for creating materials like single-walled carbon nanotubes or uniform, single-layer graphene sheets.

Versatility Across Materials

CVD is an incredibly versatile technique. It is not limited to one type of material and is frequently used to synthesize a wide range of advanced nanostructures, including:

- Carbon Nanotubes (CNTs)

- Graphene Sheets

- Gallium Nitride (GaN) Nanowires

- Metallic and Ceramic Thin Films

Understanding the Trade-offs and Considerations

While powerful, CVD is a complex industrial process with important trade-offs that must be managed for successful and responsible implementation.

High Energy Consumption

The process requires very high temperatures to initiate the chemical reactions. This makes CVD an energy-intensive method, and managing energy consumption is a key factor in its cost-effectiveness and environmental footprint.

Process Complexity

Achieving high-quality results demands precise control over numerous variables, including temperature, pressure, gas flow rates, and precursor chemistry. This complexity requires sophisticated equipment and deep process expertise.

Environmental Impact

The synthesis process is the main source of potential ecotoxicity. Factors like the choice of precursor materials, energy sources, and greenhouse gas emissions must be carefully considered to minimize the life-cycle environmental impact of the nanomaterials being produced.

Making the Right Choice for Your Goal

Selecting a synthesis method depends entirely on your end goal. CVD offers a clear pathway for applications where ultimate performance is non-negotiable.

- If your primary focus is high-performance electronics: CVD is the leading approach for creating uniform, low-defect graphene and other semiconductor films required for next-generation sensors and transistors.

- If your primary focus is cost-effective structural control: Catalytic CVD (CCVD) provides an excellent balance of cost and structural precision for synthesizing materials like carbon nanotubes.

- If your primary focus is sustainable manufacturing: You must prioritize optimizing the CVD process to limit energy consumption, select greener precursor materials, and manage emissions to reduce its life cycle ecotoxicity.

Ultimately, Chemical Vapor Deposition empowers us to engineer materials at the atomic scale, turning simple gases into the building blocks of future technology.

Summary Table:

| Aspect | Description |

|---|---|

| Core Principle | A bottom-up process using gas-phase chemical reactions to deposit solid materials atom-by-atom onto a heated substrate. |

| Key Advantage | Produces nanomaterials with exceptional purity, precise structural control, and low defect counts. |

| Common Materials | Carbon nanotubes (CNTs), graphene sheets, gallium nitride (GaN) nanowires, and various thin films. |

| Primary Consideration | High energy consumption and process complexity require sophisticated equipment and expertise. |

Ready to engineer the future with high-purity nanomaterials?

KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise Chemical Vapor Deposition processes. Whether you are developing next-generation electronics or synthesizing novel nanostructures, our solutions are designed to meet the demanding requirements of modern nanotechnology research and development.

Contact our experts today via our Contact Form to discuss how we can support your specific nanoparticle synthesis goals and help you achieve unparalleled material quality and performance.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit