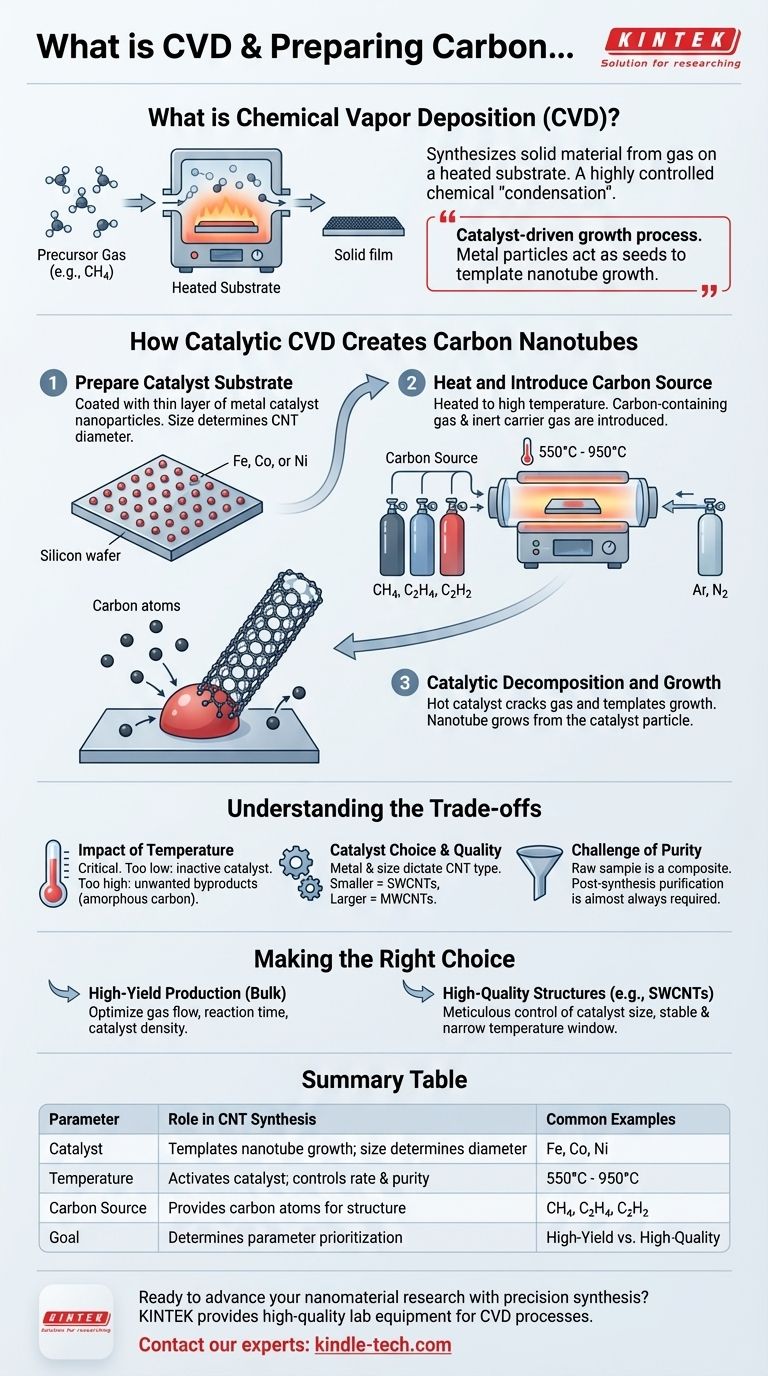

In short, Chemical Vapor Deposition (CVD) is a synthesis technique used to deposit a solid material from a gas onto a substrate. To create carbon nanotubes (CNTs), this process is adapted by introducing a carbon-containing gas into a high-temperature furnace, where metal catalyst particles break down the gas and assemble the carbon atoms into nanotube structures.

The crucial insight is that CVD for nanotubes is not just about deposition; it's a catalyst-driven growth process. Tiny metal particles act as seeds that decompose a carbon source gas and template the growth of the hollow, cylindrical nanotube structure from the bottom up.

The Core Principle: Building from Gas

What is Chemical Vapor Deposition (CVD)?

CVD is a powerful and versatile method for creating high-purity, high-performance solid materials. The general principle involves flowing a precursor gas (or vapor) into a reaction chamber where it decomposes on a heated surface, or substrate.

This chemical reaction forms a solid film or, in some cases, unique nanostructures on the substrate. Think of it as a highly controlled way of "condensing" a solid from a gas through a chemical change, rather than just a physical one like frost forming on a window.

Why CVD is Used for Nanomaterials

While CVD is famous for creating synthetic diamonds, its true strength is its adaptability. It allows for precise control over the growth environment.

By carefully managing temperature, pressure, and gas composition, scientists and engineers can grow a wide variety of advanced materials, including graphene, carbon nanofibers, and, most notably, carbon nanotubes.

How Catalytic CVD Creates Carbon Nanotubes

The synthesis of CNTs relies on a specific variant called catalytic CVD. Without the catalyst, the temperatures required to break down the carbon gas would be prohibitively high. The catalyst is the key that makes the process efficient.

Step 1: Prepare the Catalyst Substrate

The process begins not with carbon, but with a substrate (often silicon or quartz) coated with a thin layer of metal catalyst nanoparticles.

Common catalysts include iron (Fe), cobalt (Co), or nickel (Ni). The size of these catalyst particles is critical, as it directly influences the diameter of the nanotubes that will grow.

Step 2: Heat and Introduce the Carbon Source

The prepared substrate is placed inside a tube furnace and heated to a high temperature, typically between 550°C and 950°C.

Once the target temperature is reached, a carbon-containing gas (the precursor) is introduced. Common precursors include methane (CH₄), ethylene (C₂H₄), or acetylene (C₂H₂). An inert carrier gas, like argon or nitrogen, is used to transport the precursor.

Step 3: Catalytic Decomposition and Growth

This is where the synthesis happens. The hot catalyst nanoparticles perform two vital functions:

- They crack the hydrocarbon gas, breaking it down into elemental carbon and hydrogen.

- They serve as a template for growth. Carbon atoms dissolve onto the surface of the metal particle, and when it becomes saturated, the carbon precipitates out in the form of a cylindrical tube.

The nanotube literally grows out from the catalyst particle, which can remain at the tip or the base of the growing tube. This process continues as long as fresh carbon precursor is available.

Understanding the Trade-offs

Synthesizing CNTs with CVD is a powerful technique, but success depends on managing a delicate balance of competing factors.

The Impact of Temperature

Temperature is the most critical process variable. Too low, and the catalyst won't be active enough to decompose the carbon gas efficiently. Too high, and you may produce a large amount of unwanted byproducts, such as amorphous carbon, which reduces the purity of your final sample.

Catalyst Choice and Quality

The choice of metal catalyst and the size of its nanoparticles dictate the type of CNTs you produce. Smaller particles tend to produce single-walled nanotubes (SWCNTs), while larger particles typically yield multi-walled nanotubes (MWCNTs).

The Challenge of Purity

A raw, as-produced sample from a CVD process is never 100% pure CNTs. It is a composite containing the desired nanotubes, leftover catalyst particles, and disordered forms of carbon. Therefore, a post-synthesis purification step is almost always required to isolate the CNTs for use in applications.

Making the Right Choice for Your Goal

Controlling the CVD process allows you to tailor the resulting material to your objective. The parameters you prioritize will depend entirely on your end goal.

- If your primary focus is high-yield production for bulk applications: Concentrate on optimizing gas flow rates, reaction time, and catalyst density to maximize the total amount of carbon converted into nanotubes.

- If your primary focus is producing specific, high-quality structures (e.g., SWCNTs): Meticulous control over the catalyst particle size and a very stable, narrow temperature window are paramount.

Ultimately, mastering CVD for carbon nanotube synthesis is a matter of understanding and precisely controlling the interplay between the catalyst, the carbon source, and the energy you provide.

Summary Table:

| CVD Parameter | Role in CNT Synthesis | Common Examples |

|---|---|---|

| Catalyst | Templates nanotube growth; particle size determines CNT diameter | Iron (Fe), Cobalt (Co), Nickel (Ni) |

| Temperature | Activates catalyst; controls reaction rate and purity | 550°C - 950°C |

| Carbon Source | Provides the carbon atoms for nanotube structure | Methane (CH₄), Ethylene (C₂H₄), Acetylene (C₂H₂) |

| Goal | Determines parameter prioritization | High-Yield (bulk) vs. High-Quality (e.g., SWCNTs) |

Ready to advance your nanomaterial research with precision synthesis?

KINTEK specializes in providing the high-quality lab equipment and consumables essential for successful CVD processes. Whether you are optimizing for high-yield carbon nanotube production or pursuing specific, high-purity structures, our products support the precise control of temperature, gas flow, and catalyst preparation that your work demands.

Contact our experts today via our Contact Form to discuss how our solutions can help you achieve superior control and reproducibility in your CNT synthesis projects.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is modified chemical vapour deposition method? The Inside-Out Process for Ultra-Pure Optical Fibers

- What are the benefits of using dual-tube gas nozzles in LCVD? Maximize System Reliability and Film Quality Control

- What are the uses of atomic layer deposition? Achieve Perfect Thin Films for Microelectronics & More

- What is chemical vapor phase deposition? A Guide to High-Performance Thin Film Growth

- What occurs during the chemical vapor deposition (CVD) process for graphene growth? A Guide to High-Quality Synthesis

- What are the methods of CNT preparation? A Guide to Arc Discharge, Laser Ablation, and CVD

- What is the process of CVD machine? A Step-by-Step Guide to Chemical Vapor Deposition

- What is an advantage of the CVD process concerning material waste? Maximize Efficiency with Targeted Deposition