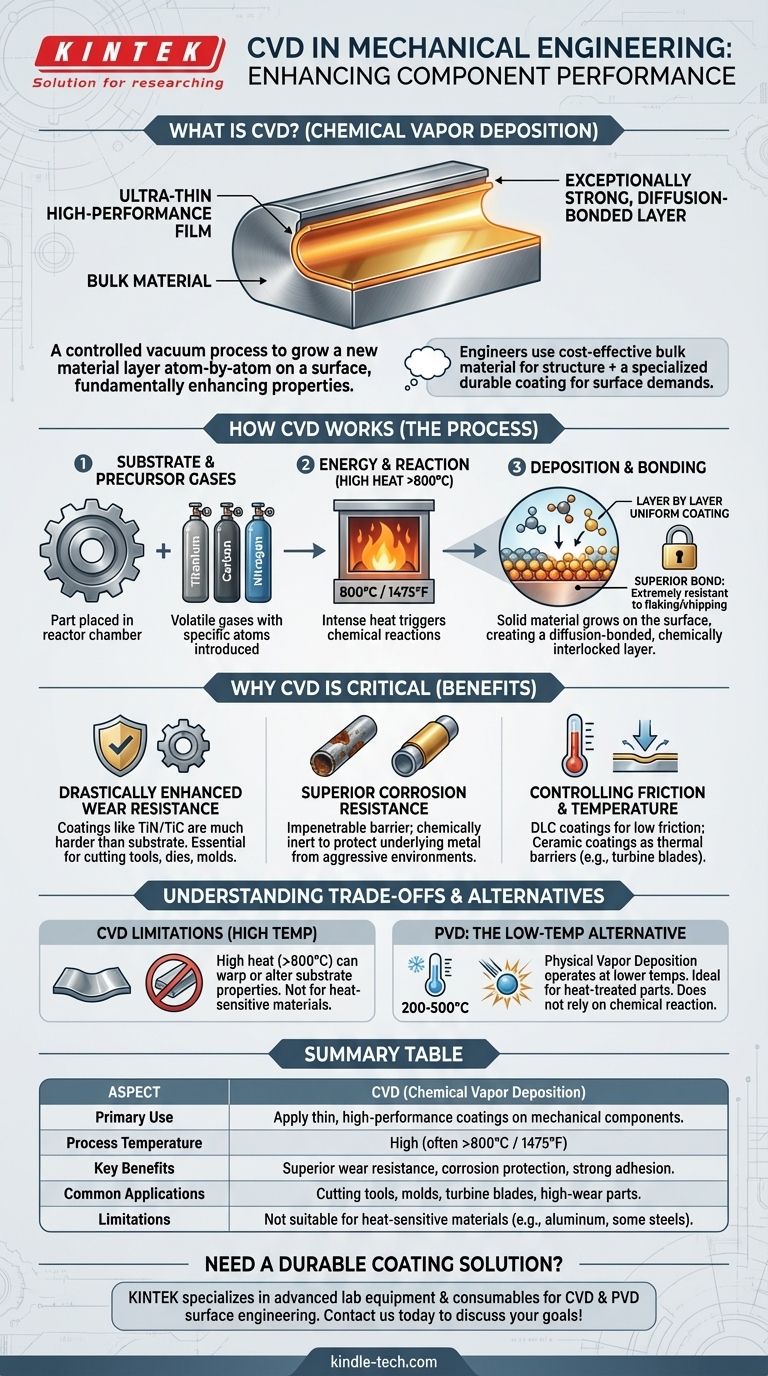

In mechanical engineering, CVD stands for Chemical Vapor Deposition. It is a highly controlled process used to apply an exceptionally thin, high-performance solid film onto the surface of a component. This is achieved inside a vacuum chamber where specific gases react and decompose at high temperatures, causing a new material layer to "grow" directly on the part's surface, fundamentally enhancing its properties.

While it sounds like a complex chemical process, its mechanical implication is straightforward. CVD allows an engineer to use a strong, cost-effective bulk material for a component's structure while adding a separate, ultra-hard, and durable coating to handle extreme surface demands like wear, friction, and corrosion.

How Chemical Vapor Deposition Works

CVD is not a simple coating like paint; it is an atom-by-atom deposition process that creates a new, fully integrated surface layer. The process relies on a few core elements working in concert.

The Core Ingredients

The process begins with a substrate, which is the mechanical part to be coated. This part is placed inside a sealed reactor chamber. Then, one or more volatile precursor gases are introduced. These gases contain the specific atoms (like titanium, carbon, or nitrogen) that will make up the final coating.

The Process in the Chamber

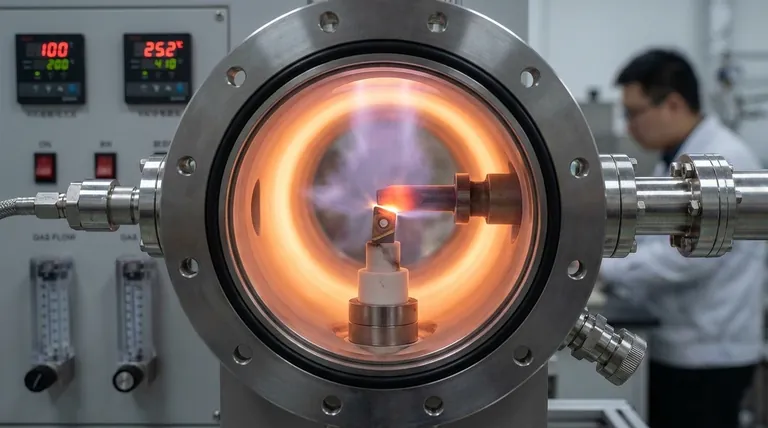

Once the part is sealed in the chamber and the precursor gases are introduced, high levels of energy—usually in the form of heat—are applied. This intense heat (often over 800°C or 1475°F) triggers chemical reactions in the gases.

These reactions cause the gas molecules to break apart, and the desired solid material "deposits" onto the hot surface of the substrate. The process is carefully controlled to build the film layer by layer, ensuring a dense and uniform coating.

The Result: A Superior Bond

Because the coating is formed through a chemical reaction directly on the surface, it creates an exceptionally strong, diffusion-bonded layer. This is fundamentally different from a physically applied layer. The CVD coating is chemically interlocked with the substrate, making it extremely resistant to flaking or chipping.

Why CVD is Critical for Mechanical Components

Engineers turn to CVD when the surface of a part is its most likely point of failure. By engineering the surface independently from the bulk, you solve performance challenges that the base material cannot handle alone.

Drastically Enhanced Wear Resistance

This is the most common application. A CVD coating like Titanium Nitride (TiN) or Titanium Carbide (TiC) can be many times harder than the hardened steel substrate it protects. This is essential for cutting tools, dies, and molds, where a sharp, wear-resistant edge determines the tool's life and performance.

Superior Corrosion Resistance

For components operating in chemically aggressive environments, a CVD coating acts as an impenetrable barrier. The deposited film can be designed to be chemically inert, protecting the underlying metal from corrosive agents that would otherwise cause it to rust or degrade rapidly.

Controlling Friction and Temperature

Specialized CVD coatings like Diamond-Like Carbon (DLC) create surfaces with an extremely low coefficient of friction. This is vital in high-performance engine components, bearings, and gears to reduce energy loss and heat generation. Other ceramic coatings can act as thermal barriers, insulating the component from extreme heat, a technique used in gas turbine blades and exhaust components.

Understanding the Trade-offs

CVD is a powerful tool, but it is not universally applicable. Understanding its limitations is key to using it effectively.

The High-Temperature Requirement

The primary limitation of traditional CVD is its high processing temperature. These temperatures can soften, warp, or negatively alter the microstructure and heat treatment of the underlying substrate. This makes it unsuitable for many hardened steels, aluminum alloys, and other temperature-sensitive materials.

The Rise of PVD as an Alternative

This temperature limitation led to the prominence of Physical Vapor Deposition (PVD). PVD is another vacuum deposition process but operates at much lower temperatures (typically 200-500°C). It does not rely on a chemical reaction, but rather on physically bombarding a solid target to vaporize it. PVD is the go-to choice for coating heat-treated parts that cannot withstand the heat of CVD.

Cost and Complexity

CVD requires significant capital investment in vacuum chambers, gas handling systems, and safety protocols. It is an industrial process best suited for high-volume or high-value components where the performance benefit justifies the cost.

Making the Right Choice for Your Goal

The decision to use CVD, PVD, or another surface treatment depends entirely on your component's material, its geometry, and its operational demands.

- If your primary focus is maximum hardness and adhesion on a heat-tolerant part: CVD is often the superior choice for materials like cemented carbides, as its chemical bond and film density are exceptional.

- If your component is heat-sensitive or requires a precise, low-friction surface: PVD is almost always the correct answer, as its lower processing temperatures preserve the substrate's mechanical properties.

- If your goal is general corrosion protection on a non-precision part: Simpler, less expensive methods like electroplating, galvanizing, or specialized painting are often more practical and cost-effective.

Ultimately, understanding CVD empowers you to design components where the surface performance is engineered just as deliberately as its mechanical structure.

Summary Table:

| Aspect | CVD (Chemical Vapor Deposition) |

|---|---|

| Primary Use | Apply thin, high-performance coatings on mechanical components. |

| Process Temperature | High (often >800°C / 1475°F) |

| Key Benefits | Superior wear resistance, corrosion protection, strong adhesion. |

| Common Applications | Cutting tools, molds, turbine blades, high-wear parts. |

| Limitations | Not suitable for heat-sensitive materials (e.g., aluminum, some steels). |

Need a durable, high-performance coating solution for your mechanical components? KINTEK specializes in advanced lab equipment and consumables for surface engineering, including CVD and PVD technologies. Whether you're developing cutting tools, engine parts, or corrosion-resistant components, our expertise ensures optimal material performance and longevity. Contact us today to discuss how we can support your laboratory's innovation and efficiency goals!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques