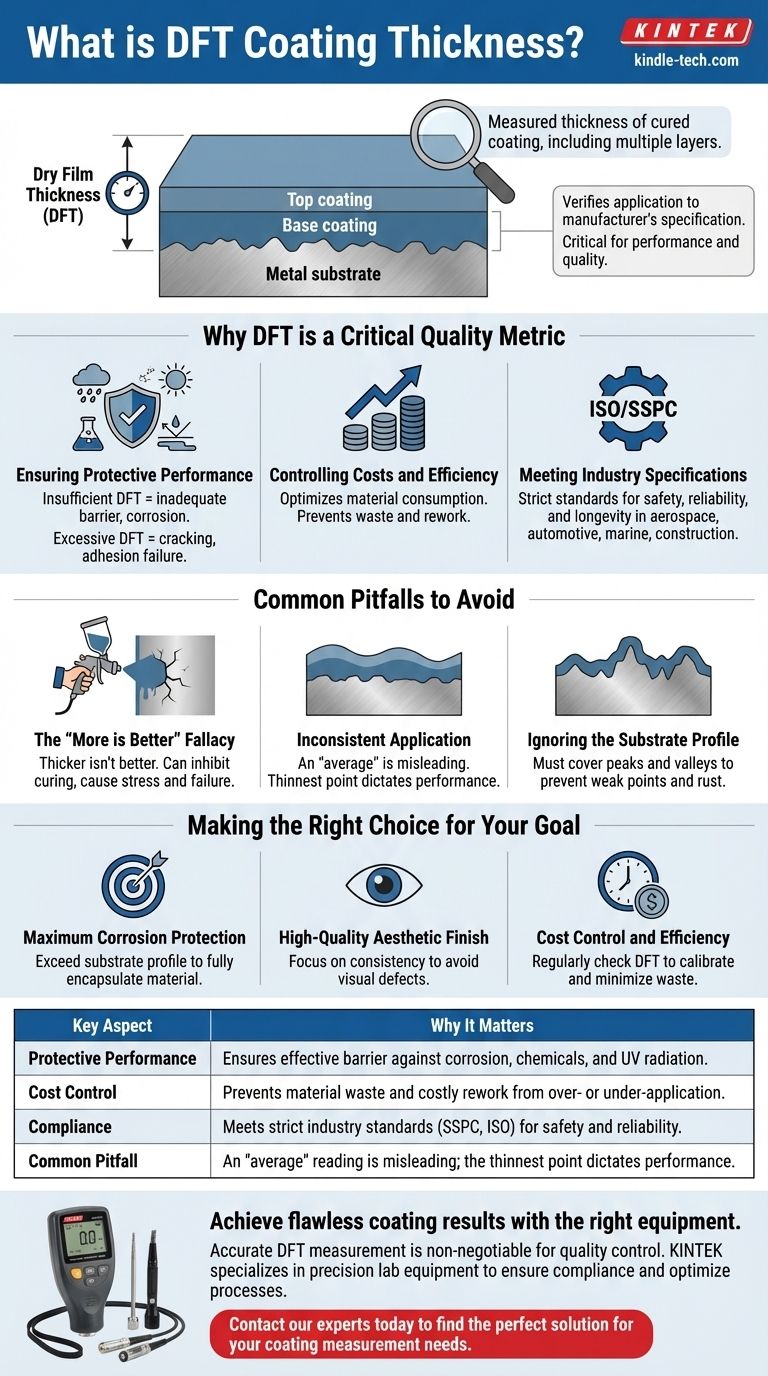

Dry Film Thickness (DFT) is the measured thickness of a coating after it has cured and dried on a substrate. This measurement represents the final, solid protective layer that remains on the surface. Whether the coating is applied in a single pass or multiple layers, DFT gauges measure the total thickness from the substrate to the final top surface.

The core purpose of measuring DFT is to verify that a coating has been applied to the manufacturer's specification. This single metric is the primary indicator of whether the coating will perform as intended, protecting the underlying material and meeting quality standards.

Why DFT is a Critical Quality Metric

Simply applying a coat of paint or powder is not enough. The thickness of that coat is directly linked to its functional lifespan and performance. An incorrect DFT can lead to premature failure, warranty claims, and significant financial loss.

Ensuring Protective Performance

The primary job of most coatings is to protect the substrate from its environment. An insufficient DFT means there isn't enough material to form an effective barrier against moisture, chemicals, or UV radiation, leading to corrosion or degradation.

Conversely, an excessive DFT can be just as damaging. Overly thick coatings can become brittle, leading to cracking, chipping, or a failure to cure properly, which compromises adhesion.

Controlling Costs and Efficiency

Coating materials represent a significant project cost. Applying a coating thicker than specified is a direct waste of material and money.

Consistent DFT measurement allows for precise control over material consumption and helps optimize the application process, preventing costly rework or over-application.

Meeting Industry Specifications

Many industries, such as aerospace, automotive, marine, and construction, operate under strict standards (like those from SSPC or ISO). These standards explicitly define required DFT ranges to ensure safety, reliability, and longevity. Failure to meet these specifications can result in project rejection.

Common Pitfalls to Avoid

Achieving the correct DFT is not always straightforward. Several common misunderstandings can compromise the quality of the final product.

The "More is Better" Fallacy

It is a frequent mistake to assume a thicker coating will provide better protection. Every coating is engineered to perform within a specific DFT range. Exceeding this range can inhibit proper curing, create internal stresses, and ultimately cause the coating to fail sooner than a correctly applied one.

Inconsistent Application

An "average" DFT reading can be dangerously misleading if the application is uneven. The overall performance of the coating system is dictated by its thinnest point. A single area with insufficient thickness can become the entry point for corrosion that undermines the entire system.

Ignoring the Substrate Profile

For coatings applied over a rough or blasted surface, the DFT is measured from the "peaks" of the surface profile. You must ensure there is enough coating material to adequately cover not just the peaks but also the "valleys" to prevent weak points where rust can begin.

Making the Right Choice for Your Goal

The target DFT is not arbitrary; it is determined by the coating's technical data sheet and the specific demands of the project.

- If your primary focus is maximum corrosion protection: You must ensure the coating thickness exceeds the substrate's surface profile to fully encapsulate the material and prevent premature rust.

- If your primary focus is a high-quality aesthetic finish: Consistency across the entire surface is more critical than absolute thickness to avoid visual defects like sagging or "orange peel."

- If your primary focus is cost control and efficiency: Regularly check DFT during the application process to calibrate equipment and technique, minimizing material waste and eliminating the need for rework.

Ultimately, mastering DFT control is fundamental to guaranteeing the quality, longevity, and cost-effectiveness of any coating project.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Protective Performance | Ensures effective barrier against corrosion, chemicals, and UV radiation. |

| Cost Control | Prevents material waste and costly rework from over- or under-application. |

| Compliance | Meets strict industry standards (SSPC, ISO) for safety and reliability. |

| Common Pitfall | An 'average' reading is misleading; the thinnest point dictates performance. |

Achieve flawless coating results with the right equipment.

Accurate DFT measurement is non-negotiable for quality control. KINTEK specializes in precision lab equipment and consumables, including coating thickness gauges, to help your laboratory ensure compliance, optimize processes, and protect your investments.

Contact our experts today to find the perfect solution for your coating measurement needs.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- What are the common specifications and shapes for PTFE cleaning baskets? Maximize Chemical Purity & Process Integrity

- What are the recommended and prohibited cleaning methods for the PTFE electrode stand? Protect Your Lab Equipment

- What are the storage requirements for the PTFE electrode stand after cleaning? Preserve Purity and Equipment Longevity

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- How does hardness change with temperature? Understand the Inverse Relationship to Prevent Failure