In essence, a double-action hydraulic press is a machine that uses hydraulic power to control both the downward pressing stroke and the upward return stroke of its ram. Unlike a standard single-action press that often relies on gravity or springs for retraction, a double-action press provides powered force in two opposing directions. This delivers significantly more control, speed, and precision over the entire operational cycle.

The critical distinction is control. While a single-action press only actively pushes in one direction, a double-action press actively pushes and pulls, giving the operator precise power over the entire process, including the speed and force of the return stroke.

First, Understanding the Standard Hydraulic Press

To grasp the "double-action" concept, we must first understand the foundation of any hydraulic press. These machines operate on a straightforward principle of force multiplication using an incompressible fluid.

Core Components

A typical hydraulic press consists of three primary systems working in unison.

The mainframe provides the structural support and rigidity needed to withstand immense forces. The power system, centered around a pump, generates the necessary pressure in the hydraulic fluid. Finally, the hydraulic control system, using valves, directs the flow of that fluid to perform work.

The Principle of Operation

The heart of the press is a hydraulic cylinder containing a piston, often called a ram. The pump forces hydraulic fluid into this cylinder, creating immense pressure that pushes the ram outward with significant force.

This movement is the "pressing stroke," where the machine performs its work, such as stamping, bending, or forming material. In a basic press, this is the only powered part of the cycle.

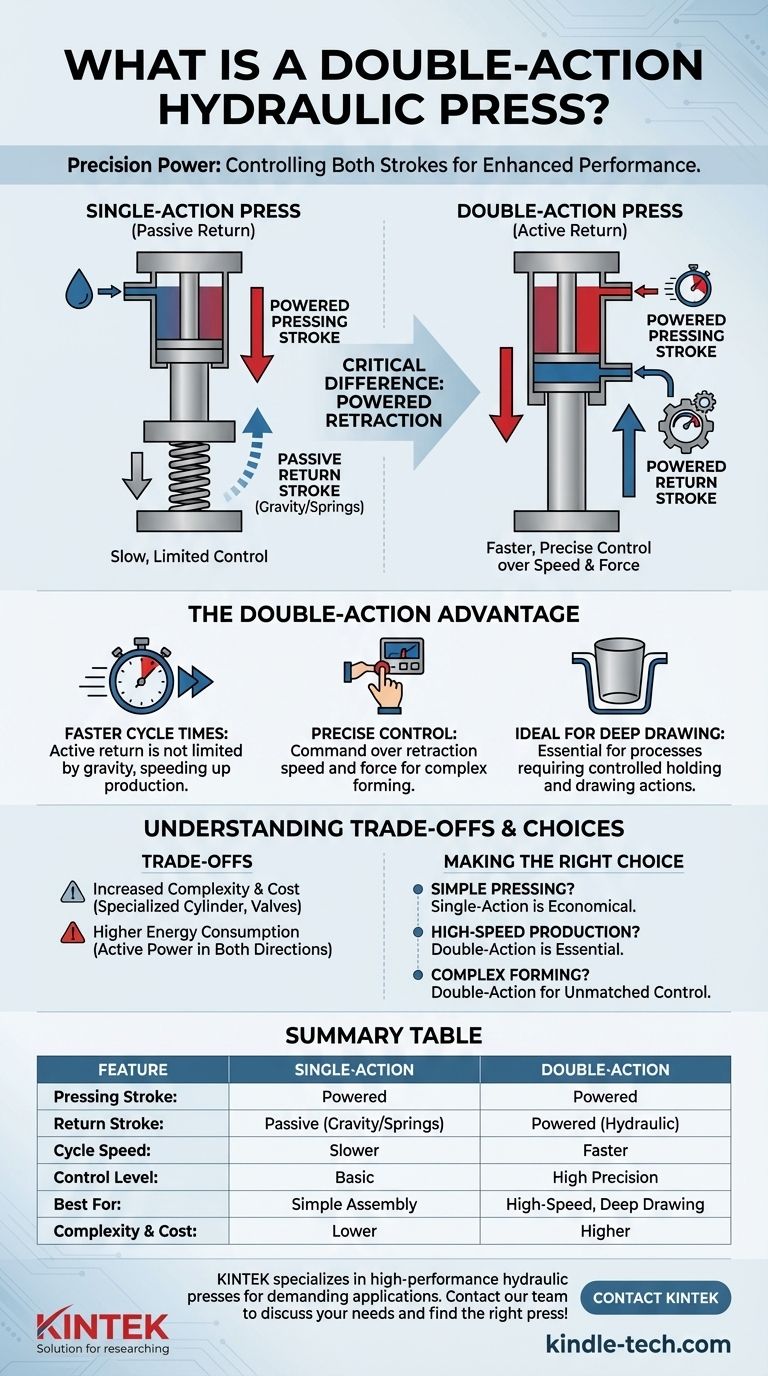

The Critical Difference: Single-Action vs. Double-Action

The term "double-action" refers directly to how the ram's movement is powered. This single design choice has major implications for the machine's performance and capabilities.

The Single-Action Press

A single-action hydraulic press uses a cylinder with one fluid port. The pump forces fluid through this port to extend the ram and perform work.

To retract the ram, the pressure is simply released. The return stroke is passive, relying on external forces like gravity or mechanical springs to bring the ram back to its starting position. This is simple and effective but can be slow and lacks precision.

The Double-Action Advantage

A double-action hydraulic press uses a specialized cylinder with two fluid ports—one on each side of the internal piston.

This allows the control system to direct high-pressure fluid to either side. Pumping fluid into the first port extends the ram (the pressing stroke), and pumping fluid into the second port actively and forcefully retracts the ram (the return stroke).

Why This Matters in Practice

Powered retraction is not just a minor feature; it is a significant performance upgrade. It allows for much faster cycle times because the return is not limited by the slow pace of gravity.

Furthermore, it offers precise control over the retraction speed and force, which is critical in complex operations like deep drawing, where one action holds the material while another performs the draw.

Understanding the Trade-offs

Choosing a double-action system involves evaluating its benefits against its inherent complexities. It is not always the superior choice for every application.

Increased Complexity and Cost

A double-action system requires a more complex hydraulic circuit, including a specialized double-action cylinder and more sophisticated directional control valves to manage the two-way fluid flow. This naturally increases the initial cost and potential maintenance requirements of the machine.

Higher Energy Consumption

Actively powering both the advance and retract strokes consumes more energy than a system that utilizes gravity for the return. For applications where cycle speed is not a primary concern, this can represent unnecessary operational cost.

When Single-Action is Sufficient

For many basic pressing, assembly, or stamping tasks, the speed and precision of the return stroke are not critical. In these cases, a simpler, more economical single-action press is often the most logical and cost-effective solution.

Making the Right Choice for Your Application

The decision between a single-action and double-action press should be driven entirely by the demands of your specific industrial process.

- If your primary focus is high-speed production or deep drawing: The controlled, rapid return of a double-action press is essential for achieving optimal cycle times and process control.

- If your primary focus is simple pressing or assembly: A more economical and mechanically simpler single-action press is likely the most appropriate and cost-effective choice.

- If you require precise control over the entire operational cycle: A double-action system provides unmatched command over both the advance and retract strokes, crucial for complex forming tasks.

Ultimately, understanding this fundamental design difference empowers you to select the right tool for the job.

Summary Table:

| Feature | Single-Action Press | Double-Action Press |

|---|---|---|

| Pressing Stroke | Powered (Hydraulic) | Powered (Hydraulic) |

| Return Stroke | Passive (Gravity/Springs) | Powered (Hydraulic) |

| Cycle Speed | Slower | Faster |

| Control Level | Basic | High Precision |

| Best For | Simple Pressing, Assembly | High-Speed Production, Deep Drawing |

| Complexity & Cost | Lower | Higher |

Need precise control and faster cycle times for your forming operations?

KINTEK specializes in high-performance hydraulic presses for demanding laboratory and industrial applications. Whether your process requires the advanced capabilities of a double-action system or the simplicity of a single-action press, our experts can help you select the ideal equipment to boost your productivity and precision.

Contact our team today to discuss your specific needs and discover the right press for your lab!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability