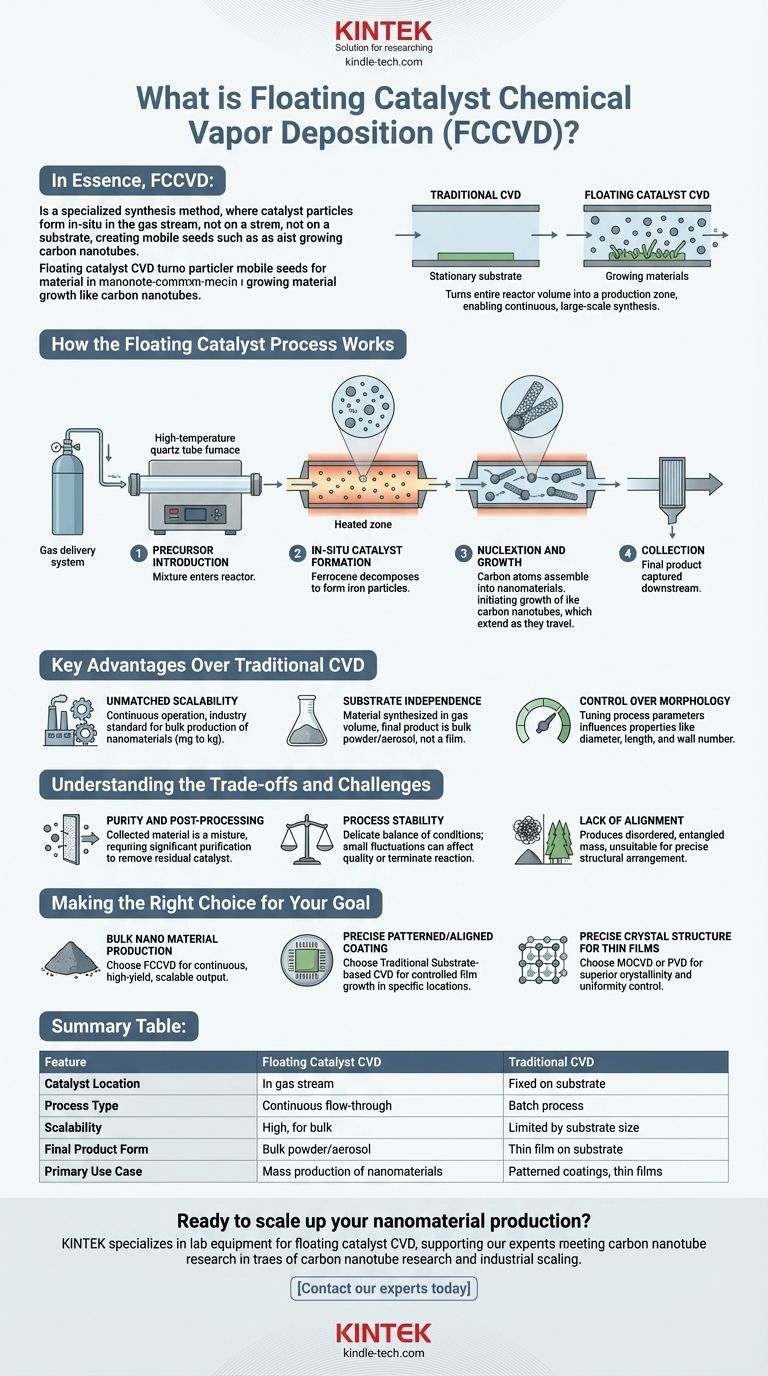

In essence, floating catalyst chemical vapor deposition (FCCVD) is a specialized synthesis method where the catalyst required for material growth is not fixed to a substrate but is introduced directly into the gas stream. These catalyst particles form in-situ within the high-temperature reactor, creating mobile "seeds" upon which the desired material, such as carbon nanotubes, grows directly in the gas phase.

While traditional Chemical Vapor Deposition (CVD) grows materials onto a stationary surface, the floating catalyst method turns the entire reactor volume into a production zone. This enables continuous, large-scale synthesis of materials that are then collected downstream, fundamentally changing the process from batch production to a scalable flow-through system.

How the Floating Catalyst Process Works

The core principle of FCCVD is to generate the catalyst nanoparticles at the same time and in the same environment as the material growth. This is typically achieved in a multi-zone furnace.

Step 1: Precursor Introduction

A gas delivery system introduces a mixture into a high-temperature reactor, typically a quartz tube furnace. This mixture contains the "precursors"—the raw chemical ingredients. For carbon nanotube synthesis, this would include a carbon source (like methane or ethanol) and a catalyst source (like ferrocene).

Step 2: In-Situ Catalyst Formation

As the gas mixture enters the hot zone of the reactor, the high temperature causes the catalyst precursor to decompose. For example, ferrocene breaks down to form tiny, nanometer-sized iron particles. These particles are the "floating catalysts," suspended and carried along by the gas flow.

Step 3: Nucleation and Growth

Simultaneously, the carbon source also decomposes on the surface of these freshly formed catalyst nanoparticles. This process, called nucleation, initiates the growth of the desired material. The carbon atoms assemble into structures like carbon nanotubes, which extend from the catalyst particles as they travel through the reactor.

Step 4: Collection

The gas stream, now carrying the synthesized nanomaterial, exits the furnace. The final product is then captured in a collection system, which can be a filter, a cold trap, or another substrate placed at the end of the reactor.

Key Advantages Over Traditional CVD

Choosing FCCVD over a conventional substrate-based method is driven by specific production goals, primarily related to scale and form.

Unmatched Scalability

Because growth is not limited by the surface area of a substrate, FCCVD can be run continuously. This makes it the industry-standard method for producing carbon nanotubes and other nanomaterials in bulk quantities, moving from milligrams to kilograms.

Substrate Independence

The material is synthesized directly within the gas volume. This means the final product is a bulk powder or aerosol, not a film attached to a specific object. This is ideal for applications where the material will be dispersed into a composite, ink, or other medium.

Control Over Morphology

By carefully tuning process parameters—such as temperature, gas flow rates, and precursor concentrations—operators can influence the final material's properties. This includes factors like the diameter, length, and wall number of carbon nanotubes.

Understanding the Trade-offs and Challenges

While powerful, the floating catalyst method introduces its own set of complexities that require a high degree of process control.

Purity and Post-Processing

The collected material is inherently a mixture of the desired product and residual catalyst particles. This necessitates significant downstream purification steps to remove metallic impurities, which can be costly and time-consuming.

Process Stability

Maintaining the perfect conditions for both catalyst particle formation and material growth simultaneously is a delicate balancing act. Small fluctuations in temperature or gas concentration can lead to inconsistent product quality or terminate the reaction altogether.

Lack of Alignment

Unlike substrate-based methods that can produce highly ordered, vertically aligned films (like a "forest" of nanotubes), FCCVD produces a disordered, entangled mass of material. This makes it unsuitable for applications requiring precise structural arrangement directly from synthesis.

Making the Right Choice for Your Goal

Selecting the correct deposition method depends entirely on the intended application and the form of the final product.

- If your primary focus is the bulk production of nanomaterials like carbon nanotubes: FCCVD is the definitive choice for its continuous operation and high-yield, scalable output.

- If your primary focus is creating a precisely patterned or aligned coating on a semiconductor wafer or component: A traditional, substrate-based CVD method offers the control needed to grow films in specific locations.

- If your primary focus is controlling the precise crystal structure for electronic or optical thin films: Substrate-based methods like MOCVD or PVD often provide superior control over crystallinity and film uniformity.

By liberating material growth from a fixed surface, floating catalyst CVD provides a powerful pathway for manufacturing advanced materials at an industrial scale.

Summary Table:

| Feature | Floating Catalyst CVD | Traditional CVD |

|---|---|---|

| Catalyst Location | In gas stream (floating) | Fixed on substrate |

| Process Type | Continuous flow-through | Batch process |

| Scalability | High (ideal for bulk production) | Limited by substrate size |

| Final Product Form | Bulk powder/aerosol | Thin film on substrate |

| Primary Use Case | Mass production of nanomaterials | Patterned coatings, thin films |

Ready to scale up your nanomaterial production? KINTEK specializes in lab equipment and consumables for advanced synthesis methods like floating catalyst CVD. Whether you're researching carbon nanotubes or scaling up to industrial production, our expertise and solutions can help you achieve consistent, high-quality results. Contact our experts today to discuss how we can support your laboratory's specific needs and accelerate your material science innovations.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis