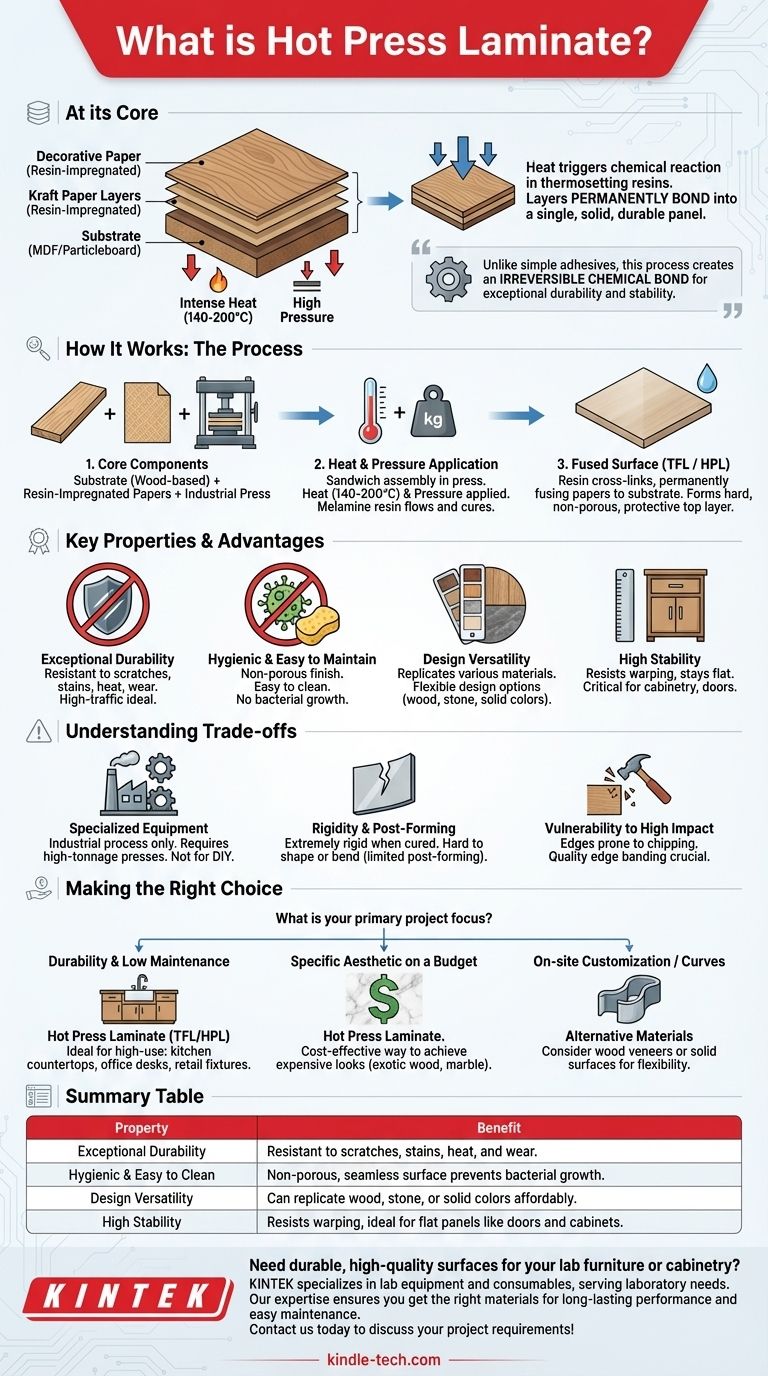

At its core, hot press laminate is a composite surface material created by fusing layers of paper and thermosetting resins onto a rigid substrate using intense heat and high pressure. The heat acts as a catalyst, triggering a chemical reaction in the resins that permanently bonds the layers into a single, solid, and highly durable panel. This process creates a non-porous, decorative, and resilient finish.

The defining characteristic of hot press lamination is its use of heat to create an irreversible chemical bond. Unlike methods that rely on simple adhesives, this process transforms separate layers into one monolithic, fused surface known for its exceptional durability and stability.

How Hot Press Lamination Works: The Process

The Core Components

The process begins with three key elements: a substrate, resin-impregnated papers, and the lamination press itself.

The substrate is typically a wood-based composite like Medium-Density Fiberboard (MDF) or particleboard, which provides the structural core.

The laminate layers consist of a decorative paper printed with a design (e.g., wood grain, stone, a solid color) and often underlying layers of Kraft paper for impact resistance. These papers are saturated with thermosetting resins, most commonly melamine.

The Role of Heat and Pressure

The substrate and resin-soaked papers are assembled into a "sandwich" and placed into a large industrial press.

The press applies intense heat (typically 140-200°C / 280-390°F) and significant pressure. The heat causes the melamine resin to flow and then cure, initiating a cross-linking process that permanently fuses the paper layers to each other and to the substrate.

The Result: A Fused Surface

This process doesn't just glue the layers together; it creates a new, integrated surface. The cured resin forms a hard, protective top layer that is seamless and extremely tough. The resulting panel is known as Thermally Fused Laminate (TFL) or, in a slightly different process, High-Pressure Laminate (HPL).

Key Properties and Advantages

Exceptional Durability

The cured melamine surface is highly resistant to scratches, stains, heat, and general wear. This makes it an ideal choice for high-traffic and demanding environments.

Hygienic and Easy to Maintain

The lamination process creates a non-porous finish, leaving no place for dirt or bacteria to hide. This sealed surface is incredibly easy to clean and does not require special polishes or treatments.

Design Versatility

Because the visual element is a printed paper layer, hot press laminates can replicate the look of virtually any material. This allows for incredible design flexibility, from convincing wood grains and stone textures to vibrant solid colors.

High Stability

The combination of a stable substrate and a fused surface layer results in a panel that resists warping and stays flat over time, a critical attribute for cabinetry, doors, and furniture.

Understanding the Trade-offs

The Need for Specialized Equipment

Hot press lamination is strictly an industrial process. It requires massive, high-tonnage presses and significant energy input, meaning it can only be done in a factory setting. It is not a DIY or on-site process.

Rigidity and Post-Forming Challenges

Once the panel is cured, it is extremely rigid. While some specialized grades of High-Pressure Laminate can be bent into gentle curves (post-forming), most hot-pressed panels cannot be easily shaped or bent.

Vulnerability to High Impact

Like any hard, rigid surface, the edges of a hot press laminate panel can be prone to chipping if struck by a heavy or sharp object. This is why high-quality, durable edge banding is critical to the longevity of the final product.

Making the Right Choice for Your Project

Understanding the manufacturing process allows you to determine when a hot-pressed product is the optimal choice for your application.

- If your primary focus is durability and low maintenance: Hot press laminates are the ideal choice for high-use surfaces like kitchen countertops, office desks, cabinetry, and retail fixtures.

- If your primary focus is achieving a specific aesthetic on a budget: This material provides a cost-effective way to achieve the look of expensive materials like exotic wood or marble without the associated cost and maintenance.

- If your primary focus is on-site customization or complex curves: You may need to consider alternative materials like wood veneers or solid surfaces that offer more flexibility for custom shaping.

By recognizing that heat and pressure create its fundamental strength, you can confidently specify and utilize this versatile and resilient material.

Summary Table:

| Property | Benefit |

|---|---|

| Exceptional Durability | Resistant to scratches, stains, heat, and wear. |

| Hygienic & Easy to Clean | Non-porous, seamless surface prevents bacterial growth. |

| Design Versatility | Can replicate wood, stone, or solid colors affordably. |

| High Stability | Resists warping, ideal for flat panels like doors and cabinets. |

Need durable, high-quality surfaces for your lab furniture or cabinetry? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our expertise ensures you get the right materials for long-lasting performance and easy maintenance. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification