An integral quench furnace, often called an IQF or a "sealed quench" furnace, is a type of industrial heat treatment furnace that combines the heating and quenching stages into a single, sealed unit. This design uses a protective atmosphere to heat parts and then transfers them to an integrated quench tank (typically containing oil) without exposing them to outside air. It is the workhorse of the industry for surface hardening processes like carburizing.

The central advantage of an integral quench furnace is its ability to deliver highly consistent and repeatable metallurgical results by eliminating the variable of air exposure between heating and quenching, which prevents surface oxidation and decarburization.

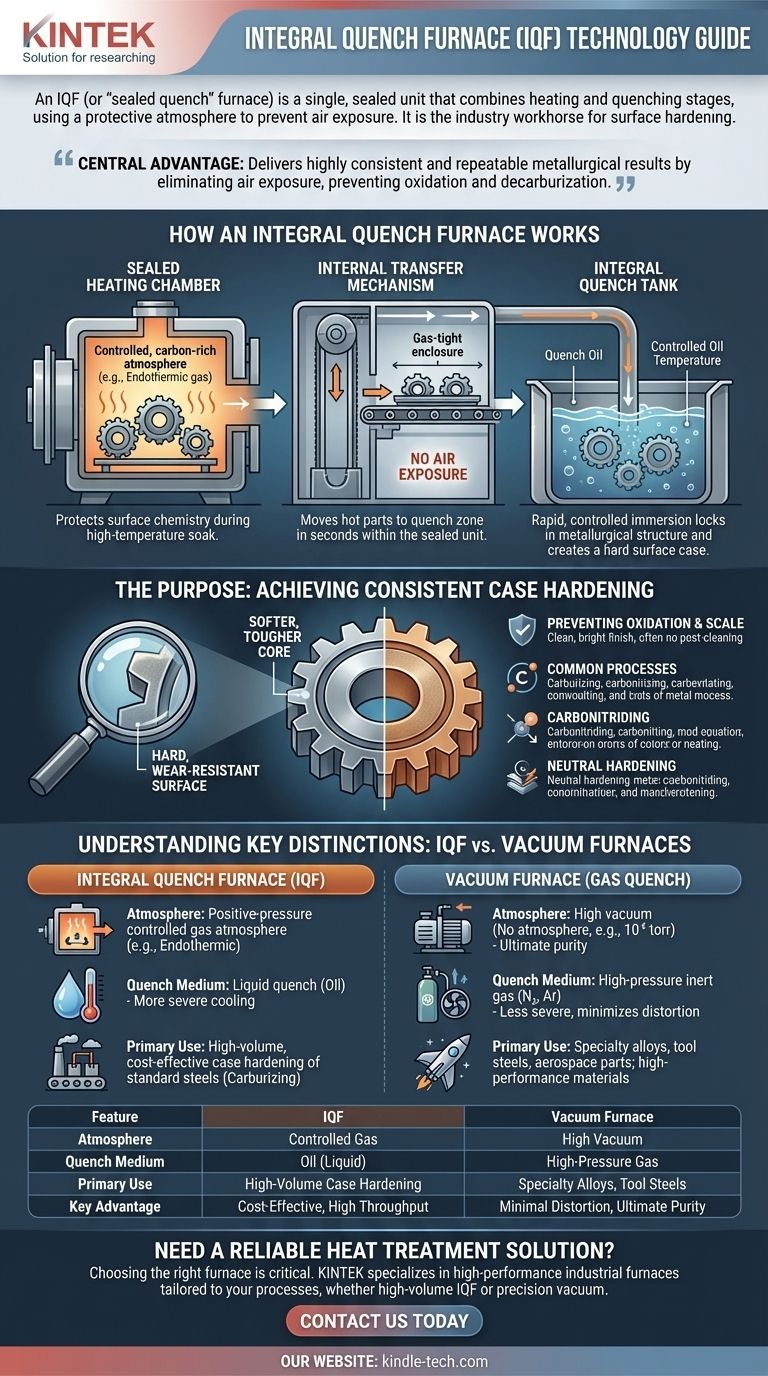

How an Integral quench Furnace Works

The design of an IQF is key to its function. It consists of a few core sections that work in sequence within a single, gas-tight enclosure.

The Sealed Heating Chamber

Parts are first loaded into a heating chamber filled with a precisely controlled, carbon-rich atmosphere. This is typically an endothermic gas, which prevents the steel's surface from losing carbon (decarburization) and can be enriched to add carbon (carburizing).

This controlled environment is the defining feature that protects the part's surface chemistry during the high-temperature soak.

The Internal Transfer Mechanism

Once the parts have been heated for the required time, an internal automation system—often an elevator or a pusher mechanism—moves the entire workload out of the heating chamber.

This transfer happens entirely within the sealed furnace, moving the hot parts into the quench zone in a matter of seconds.

The Integral Quench Tank

The parts are immediately submerged into a large tank of quench oil located directly below or in front of the heating chamber. This rapid, controlled immersion locks in the desired metallurgical structure, creating a hard surface case. The oil's temperature is also carefully controlled to manage cooling rates and minimize distortion.

The Purpose: Achieving Consistent Case Hardening

The IQF is not just a piece of equipment; it is a system designed to solve a specific manufacturing challenge: creating a hard, wear-resistant surface on a softer, tougher core.

Preventing Oxidation and Scale

By never exposing the hot steel to oxygen, the IQF process prevents the formation of scale (iron oxides) on the part's surface. This results in a clean, bright finish that often requires no subsequent cleaning operations.

Common Processes

IQFs are the standard for several critical heat treatment processes:

- Carburizing: Diffusing carbon into the surface of low-carbon steel to enable the formation of a hard, high-carbon case upon quenching.

- Carbonitriding: A modified version of carburizing where both carbon and nitrogen are diffused into the surface, which improves hardness and wear resistance.

- Neutral Hardening: Heating a medium- or high-carbon steel part to its hardening temperature in a protective atmosphere and then quenching it, without changing its surface chemistry.

Understanding Key Distinctions: IQF vs. Vacuum Furnaces

The reference you provided describes a vacuum gas quench furnace, which serves a similar purpose but operates on a different principle. Understanding the difference is crucial.

Atmosphere vs. Vacuum

An IQF uses a positive-pressure controlled gas atmosphere to protect the part. A vacuum furnace removes the atmosphere entirely, creating a near-perfect vacuum (e.g., 10⁻⁶ torr) to prevent any surface reactions.

Quenching Method

A traditional IQF uses a liquid quench, most commonly oil. A vacuum furnace, as described in your reference, uses a high-pressure inert gas quench (e.g., nitrogen or argon at 2 to 10 bar pressure) to cool the parts. Gas quenching is generally less severe than oil quenching, reducing the risk of part distortion.

Applications and Materials

IQF furnaces are ideal for high-volume, cost-effective case hardening of common carbon and alloy steels.

Vacuum furnaces are typically preferred for high-performance materials like tool steels, stainless steels, and aerospace alloys where ultimate surface purity is required and distortion must be minimized. The high temperatures (up to 2400°F / 1315°C) and gas quenching capabilities are suited for these specialized applications.

Making the Right Choice for Your Process

Your choice of furnace technology depends entirely on the material, part geometry, and desired outcome.

- If your primary focus is high-volume, cost-effective case hardening of standard steels: The integral quench furnace is the definitive industry standard for its reliability and efficiency.

- If your primary focus is processing specialty alloys, tool steels, or parts with complex geometries where distortion is a major concern: A vacuum furnace with high-pressure gas quenching is the superior technical solution.

- If your primary focus is simple hardening with no surface chemistry requirements and a tolerance for post-process cleaning: A more basic configuration, like a box furnace with a separate, open quench tank, may suffice.

Ultimately, selecting the correct thermal processing equipment is about matching the tool's capabilities precisely to your metallurgical and manufacturing goals.

Summary Table:

| Feature | Integral Quench Furnace (IQF) | Vacuum Furnace (Gas Quench) |

|---|---|---|

| Atmosphere | Controlled Gas (Endothermic) | High Vacuum (No Atmosphere) |

| Quench Medium | Oil (Liquid) | High-Pressure Inert Gas (e.g., N₂) |

| Primary Use | High-Volume Case Hardening (Carburizing) | Specialty Alloys, Tool Steels |

| Key Advantage | Cost-Effective, High Throughput | Minimal Distortion, Ultimate Purity |

Need a Reliable Heat Treatment Solution for Your Lab or Production Line?

Choosing the right furnace is critical to achieving your metallurgical goals. At KINTEK, we specialize in providing high-performance lab equipment, including industrial furnaces tailored to your specific processes.

Whether you're engaged in high-volume case hardening with an IQF or require the precision of a vacuum furnace for specialty alloys, our experts can help you select the ideal system for consistent, repeatable results.

Contact us today via our [#ContactForm] to discuss your application, and let KINTEK equip your lab for success.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What are the characteristics of the slipping, slumping, and rolling modes of bed motion? Optimize Your Rotary Process

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion

- Why are high temperatures required when sintering stainless steels? Unlock Pure, High-Density Results

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases