In IR spectroscopy, potassium bromide (KBr) is used as a transparent matrix to hold a solid sample in the path of the infrared beam. It is an alkali halide that can be mixed with a powdered sample and compressed under high pressure. This process forms a thin, glass-like disc or "pellet" that is transparent to infrared radiation, allowing the spectrometer to measure the sample's absorption spectrum without interference from the holding material.

The core value of KBr is its unique combination of properties: it is transparent to infrared light across a wide range of frequencies and becomes plastic under pressure, allowing it to form a solid, uniform medium that effectively holds the sample for analysis.

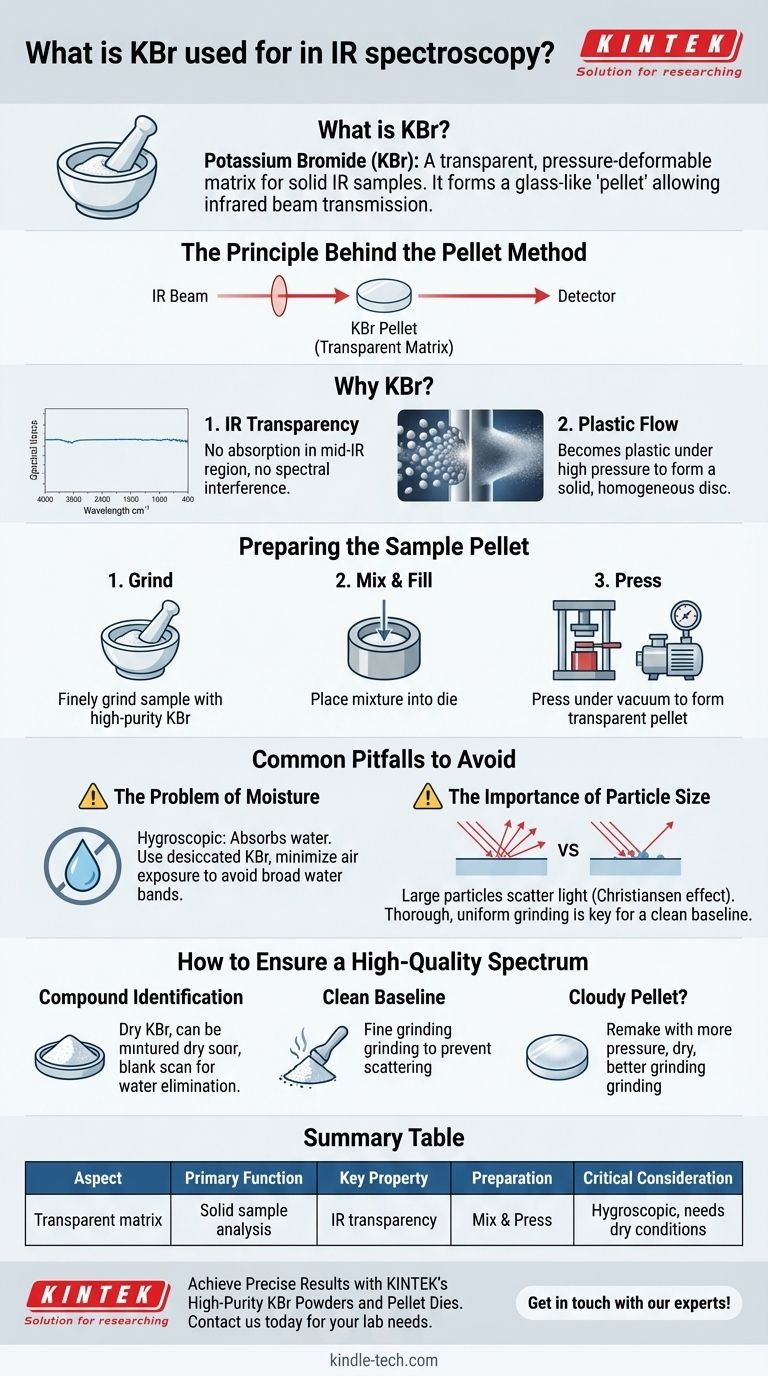

The Principle Behind the KBr Pellet Method

To understand why KBr is the industry standard for solid-sample IR spectroscopy, we must look at its specific physical and optical properties. The entire technique is built around KBr's ability to act as an invisible window for infrared light.

Why KBr is an Ideal Matrix

Potassium bromide is an ionic salt. Its chemical bonds do not absorb infrared radiation in the mid-infrared region (4000-400 cm⁻¹) where most organic and inorganic functional groups are identified.

This IR transparency is the single most important property. It ensures that any absorption peaks detected by the instrument originate from the sample, not from the matrix holding it.

The "Plastic Flow" Phenomenon

When subjected to immense pressure (typically several tons), the crystalline structure of KBr deforms and flows. This is what the reference means when it says the material becomes "plastic."

The individual KBr particles fuse together, trapping the finely ground sample particles within a solid, homogenous disc. The final pellet is physically robust and optically clear, much like a small window.

Preparing the Sample Pellet

The process involves finely grinding a small amount of the solid sample with a much larger amount of high-purity KBr powder, typically in an agate mortar and pestle.

This mixture is then placed into a pellet die and pressed under a vacuum. The vacuum helps remove trapped air and moisture, which is critical for creating a high-quality, transparent pellet.

Common Pitfalls to Avoid

While the KBr pellet method is powerful, its success depends on careful technique. Several common issues can compromise the quality of the final spectrum.

The Problem of Moisture

KBr is hygroscopic, meaning it readily absorbs moisture from the atmosphere. Water has very strong and broad absorption bands in the IR spectrum, which can easily obscure important peaks from your sample.

It is critical to use desiccated (dried) KBr and to minimize the sample's exposure to air during preparation. Proper drying of the final pellet is also essential.

The Importance of Particle Size

If the sample particles are too large, they will scatter the infrared light rather than absorbing it. This phenomenon, known as the Christiansen effect, results in a distorted, sloping baseline and can make the spectrum difficult to interpret.

Thorough and uniform grinding is the key to minimizing scattering and achieving a flat, clean baseline. The sample particles must be smaller than the wavelength of the IR radiation being used.

The Need for a Background Scan

Before running the sample, you must run a background scan using a pure KBr pellet (a "blank") or an empty pellet holder.

This allows the instrument's software to subtract any absorption signals from atmospheric CO₂ and water vapor, as well as any scattering effects or minor impurities present in the KBr itself.

How to Ensure a High-Quality Spectrum

Your approach to sample preparation should be dictated by your analytical goal. Careful technique is the foundation of a reliable result.

- If your primary focus is compound identification: Ensure your KBr is impeccably dry and run a high-quality background scan with a pure KBr blank to eliminate any confusing peaks from water.

- If your primary focus is getting a clean baseline: Grind the sample and KBr mixture until it is an exceptionally fine, flour-like powder to prevent light scattering.

- If your pellet appears cloudy or opaque: This indicates insufficient pressure, trapped moisture, or poor grinding. The pellet must be remade to ensure the IR beam can pass through it effectively.

Understanding the properties of potassium bromide is the key to mastering this fundamental spectroscopic technique.

Summary Table:

| Aspect | Key Role of KBr |

|---|---|

| Primary Function | Transparent matrix for solid sample analysis |

| Key Property | IR transparency in the mid-IR region (4000-400 cm⁻¹) |

| Preparation | Mixed with sample and pressed into a pellet under high pressure |

| Critical Consideration | Hygroscopic; requires dry conditions to avoid water interference |

Achieve precise and reliable results in your IR spectroscopy work. The quality of your sample preparation directly impacts your data. KINTEK specializes in high-purity KBr powders and reliable pellet dies designed for laboratory spectroscopy. Our products help you create perfect pellets, minimizing moisture and scattering issues for clear, interpretable spectra. Contact us today to discuss how our lab equipment and consumables can support your analytical needs and enhance your laboratory's efficiency. Get in touch with our experts!

Visual Guide

Related Products

- kbr pellet press 2t

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is a KBr pellet? A Guide to Preparing Solid Samples for IR Spectroscopy

- What is KBr disc method in IR spectroscopy? A Guide to Solid Sample Analysis

- Why only KBr is used in IR spectroscopy? The Truth About the Best Material for Your Sample

- Why KBr is used for IR spectroscopy? The Ideal Medium for Solid Sample Analysis

- Why do we use KBr in IR spectroscopy? Achieve Clear, High-Quality Solid Sample Analysis