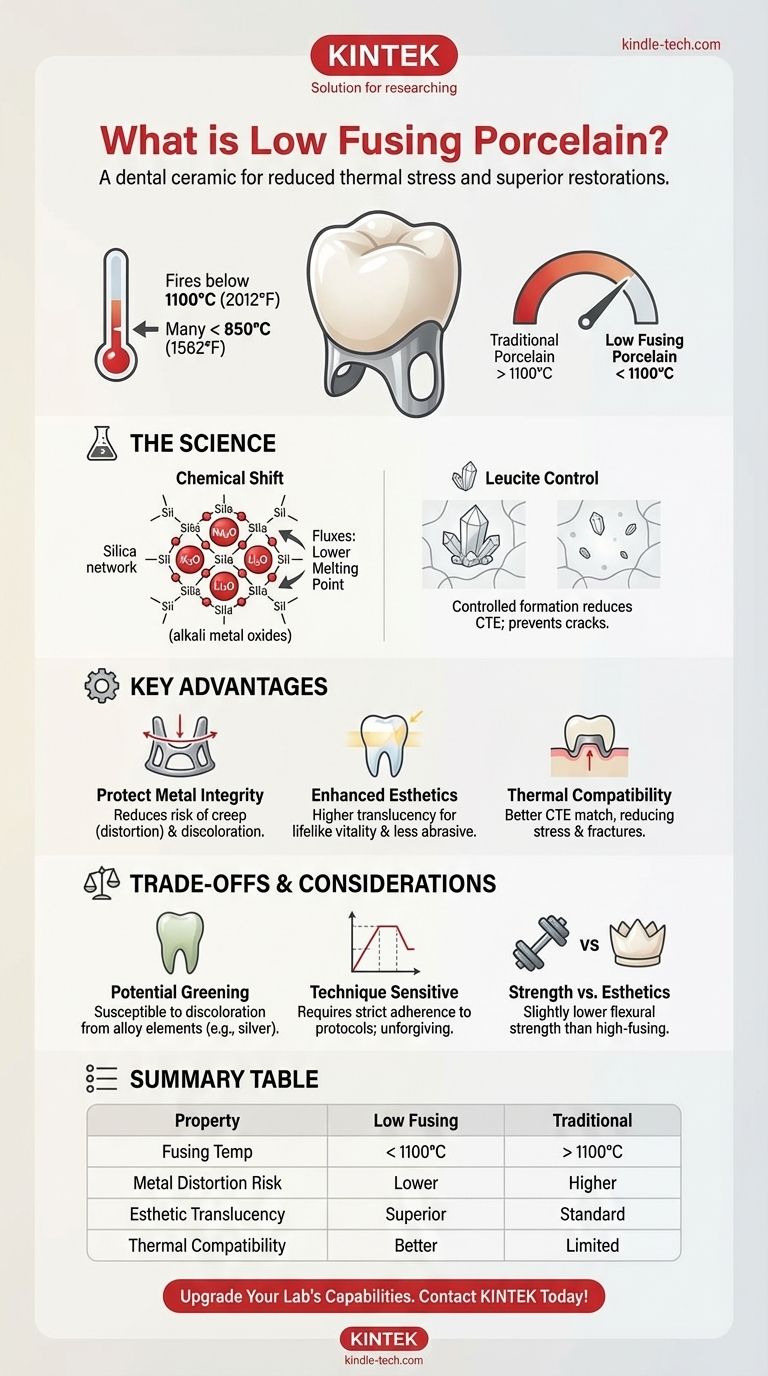

At its core, low fusing porcelain is a type of dental ceramic designed to be fired and fused at significantly lower temperatures than traditional porcelains. Specifically, these materials mature at temperatures generally below 1100°C (2012°F), with many modern "ultra-low" formulations firing below 850°C (1562°F). This lower temperature requirement is not just a minor detail; it is a fundamental shift that reduces thermal stress on the underlying metal framework of a crown or bridge, leading to more stable and esthetic restorations.

The adoption of low fusing porcelain is driven by a critical need to protect the integrity of metal substructures during fabrication. Its lower firing temperature minimizes the risk of framework distortion and discoloration, while often providing superior esthetics compared to its high-temperature counterparts.

The Science Behind Low Fusing Temperatures

To understand the benefits of low fusing porcelain, we must first look at its unique chemical composition and structure. The ability to fuse at a lower temperature is an intentional and highly engineered property.

A Shift in Chemical Composition

Traditional dental porcelains are primarily based on a feldspar glass network. To lower the melting point, manufacturers increase the concentration of alkali metal oxides, such as sodium oxide (Na₂O), potassium oxide (K₂O), and lithium oxide (Li₂O).

These oxides act as fluxes, disrupting the strong silicate glass network and allowing it to flow and mature at a lower temperature. This is the primary mechanism that defines a porcelain as "low fusing."

Controlling Leucite Crystals

During the cooling of feldspathic porcelain, leucite crystals form within the glassy matrix. These crystals have a high coefficient of thermal expansion (CTE).

In low fusing porcelains, the formation and amount of leucite are carefully controlled. Reducing the leucite content helps lower the overall CTE of the porcelain, making it more compatible with a wider range of modern dental alloys and reducing the risk of cracks upon cooling.

Fusing Temperatures as a Classification

Dental porcelains are broadly categorized by their firing temperatures, which dictates their application:

- High Fusing: >1300°C (>2372°F). Used primarily for manufacturing denture teeth.

- Medium Fusing: 1101°C - 1300°C (2013°F - 2372°F). Historically used for PFM restorations, but less common today.

- Low Fusing: 850°C - 1100°C (1562°F - 2012°F). The standard for many modern porcelain-fused-to-metal (PFM) restorations.

- Ultra-Low Fusing: <850°C (<1562°F). Often used for corrections, add-ons, and with alloys that have a low melting range.

Key Advantages of Lower Firing Temperatures

The shift toward low fusing materials is a direct response to the challenges encountered with high-temperature fabrication processes.

Protecting the Metal Substructure

Repeatedly heating a metal alloy framework to high temperatures can cause creep, a form of permanent microscopic distortion. This can compromise the passive fit of a crown or bridge.

Lower firing temperatures significantly reduce the risk of creep, ensuring the metal substructure remains accurate and stable throughout the porcelain layering process.

Enhanced Esthetics and Vitality

Low fusing porcelains often have a finer microstructure and can be formulated to exhibit higher translucency. This allows them to mimic the optical properties of a natural tooth more effectively, resulting in a more vital and lifelike appearance.

Furthermore, their fine-particle structure generally makes them less abrasive to the enamel of opposing teeth, a significant clinical benefit for long-term oral health.

Improved Thermal Compatibility

A successful PFM restoration requires the porcelain and metal to have closely matched coefficients of thermal expansion (CTE). A mismatch can create immense stress during cooling, leading to fractures.

Low fusing porcelains can be engineered with a lower CTE, providing a better match for many high-noble, noble, and base-metal alloys used in dentistry today.

Understanding the Trade-offs and Pitfalls

While highly advantageous, low fusing porcelain is not without its own set of challenges and required considerations.

Potential for "Greening"

The most well-known issue is greening, a discoloration of the porcelain. This occurs when certain elements in the metal alloy, particularly silver, vaporize during firing and get absorbed into the porcelain matrix.

Because this vaporization can happen at lower temperatures, low fusing porcelains can be susceptible to this issue. Manufacturers mitigate this with specialized opaque layers and by providing clear guidelines on alloy selection.

Technique Sensitivity

Achieving optimal results with low fusing porcelain requires strict adherence to the manufacturer's protocols. Firing schedules, including temperature ramp rates and hold times, are precisely calculated.

Deviating from these instructions can lead to poor bonding, inadequate density, or compromised esthetics. These materials are often less forgiving of procedural error than their high-fusing predecessors.

Balancing Strength and Esthetics

The same chemical fluxes that lower the fusing temperature can sometimes result in a lower final flexural strength compared to some high-fusing materials.

While more than strong enough for single units and short-span bridges, this trade-off must be considered when planning very long-span or complex restorations where maximum fracture resistance is the top priority.

Making the Right Choice for Your Restoration

Selecting the right type of porcelain is a decision based on the specific clinical or technical requirements of the case.

- If your primary focus is optimal esthetics for single-unit crowns: Low fusing porcelain is an excellent choice for its translucency and kindness to opposing dentition.

- If you are fabricating a long-span bridge with a robust alloy: You must ensure the low fusing porcelain's strength is adequate, though its ability to prevent framework distortion remains a major benefit.

- If you are working with silver-containing or other sensitive alloys: Low fusing porcelain is almost always the required choice to prevent framework distortion and potential greening discoloration.

Ultimately, understanding the properties of low fusing porcelain allows you to masterfully balance the demands of strength, esthetics, and material compatibility for superior restorative outcomes.

Summary Table:

| Property | Low Fusing Porcelain | Traditional Porcelain |

|---|---|---|

| Fusing Temperature | < 1100°C (< 2012°F) | > 1100°C (> 2012°F) |

| Metal Framework Distortion Risk | Lower | Higher |

| Esthetic Translucency | Superior | Standard |

| Thermal Compatibility | Better with modern alloys | More limited |

| Common Applications | Modern PFM crowns/bridges | Denture teeth, historical PFM |

Upgrade your dental lab's capabilities with KINTEK's advanced dental ceramics. Our low fusing porcelains are engineered to deliver superior esthetics while protecting your metal substructures from distortion. Whether you're crafting single-unit crowns or complex bridges, our materials ensure optimal thermal compatibility and lasting results. Contact our dental experts today to find the perfect porcelain solution for your laboratory's needs!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What factors determine the maturation of dental porcelain during firing? Master the Time-Temperature Relationship

- What is furnace calibration? Ensure Precise Temperatures for Perfect Dental Restorations

- Do dentists still use porcelain? Discover the High-Tech Ceramics Transforming Modern Dentistry

- What is a recommended maintenance practice for modern ceramic furnaces? Prioritize Firmware Updates for Peak Performance

- How can consistent heating of ceramic restorations be achieved within a furnace? Master Your Furnace's Heat Dynamics

- What are the failures of zirconia? Avoid Fracture and Debonding with Proper Protocol

- What are the different types of ceramics in dentistry? Choose the Right Material for Strength & Aesthetics

- What is the strongest type of zirconia? A Guide to Choosing the Right Dental Zirconia