At its core, Low Pressure Chemical Vapor Deposition (LPCVD) is a manufacturing process used to grow extremely high-quality, uniform thin films on a substrate. It operates inside a vacuum chamber where volatile precursor gases are introduced and react on a heated surface. The "low pressure" condition is the critical factor that distinguishes it, enabling the creation of films with exceptional purity and conformity, even over complex three-dimensional structures.

The central purpose of using low pressure in Chemical Vapor Deposition is not just to create a vacuum, but to precisely control the chemical reaction environment. This control allows gas molecules to coat every surface of a component uniformly, a crucial capability for manufacturing modern microelectronics and high-performance materials.

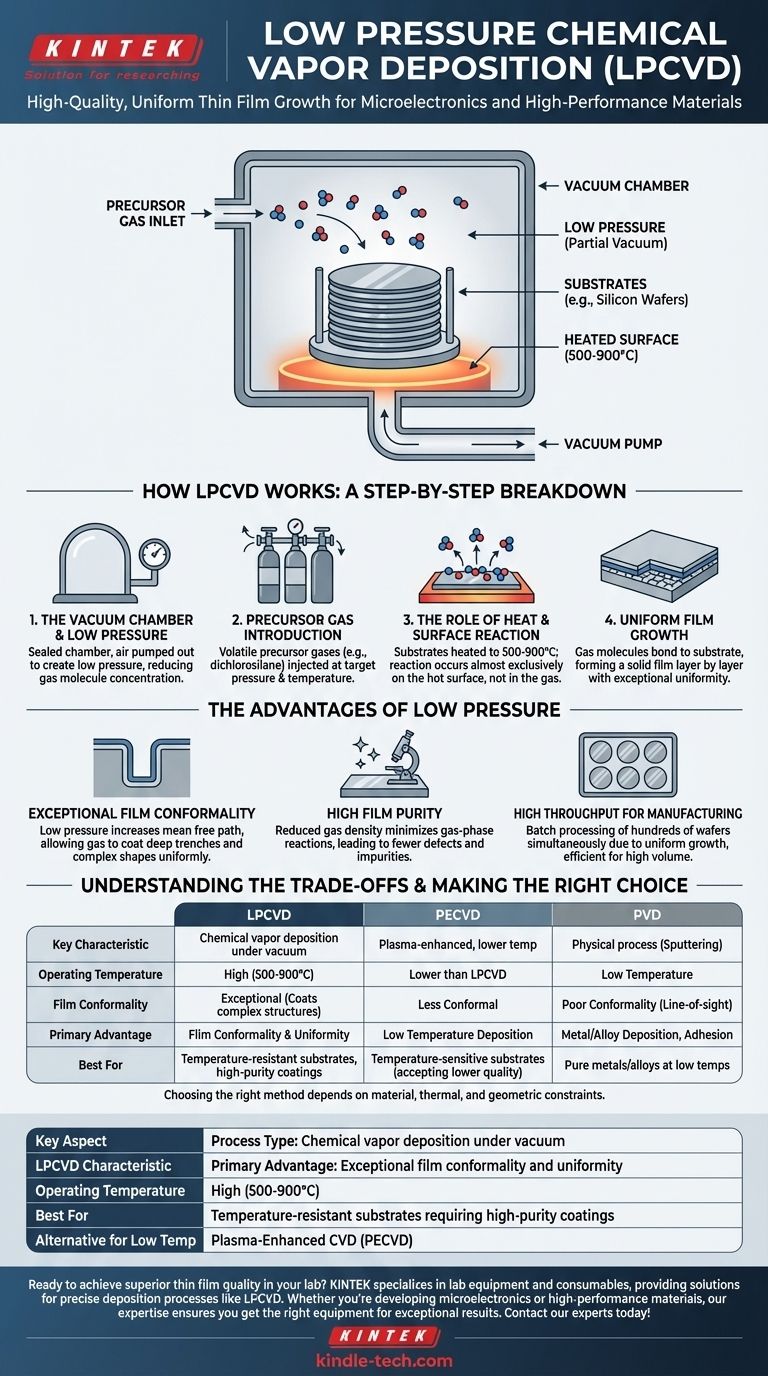

How LPCVD Works: A Step-by-Step Breakdown

LPCVD is a surface-reaction-limited process, meaning the film growth is controlled by the chemical reaction happening directly on the substrate, not by how fast gas is supplied. This principle is key to its high performance.

The Vacuum Chamber and Low Pressure

The process begins by placing substrates (such as silicon wafers) into a sealed chamber and pumping out the air to create a low-pressure, or partial vacuum, environment. This reduces the concentration of all gas molecules, including the reactive ones that will be introduced later.

Precursor Gas Introduction

Once the chamber is at the target pressure and temperature, one or more volatile precursor gases are injected. These gases contain the chemical elements that will make up the final film. For example, to deposit silicon nitride, gases like dichlorosilane and ammonia might be used.

The Role of Heat and Surface Reaction

The substrates are heated to a specific, high temperature (often 500-900°C). This thermal energy is what drives the chemical reaction. Crucially, the reaction is designed to happen almost exclusively on the hot substrate surface, not in the gas phase above it.

Uniform Film Growth

As precursor gas molecules land on the hot surface, they decompose or react, bonding to the substrate and forming a solid, stable thin film. Because the low pressure allows gas molecules to spread out and reach all areas evenly, the film builds up with exceptional uniformity layer by layer.

The Advantages of Low Pressure

The decision to operate at low pressure is deliberate and unlocks several key benefits that are impossible to achieve at atmospheric pressure.

Exceptional Film Conformality

The most significant advantage of LPCVD is its ability to produce highly conformal films. The low pressure increases the mean free path of gas molecules—the average distance they travel before colliding with another molecule. This allows them to diffuse deep into trenches, holes, and around complex shapes before reacting, resulting in a film of uniform thickness everywhere.

High Film Purity

By reducing the overall gas density, the likelihood of undesirable chemical reactions occurring in the gas phase (away from the substrate) is minimized. This prevents tiny particles from forming and falling onto the film, resulting in a final coating with very few defects or impurities.

High Throughput for Manufacturing

Because the film growth is so uniform, substrates can be stacked vertically and close together in "batch" furnaces. This allows hundreds of wafers to be processed simultaneously in a single run, making LPCVD an economically efficient process for high-volume manufacturing.

Understanding the Trade-offs

No process is perfect for every application. The primary limitation of LPCVD is a direct consequence of its core mechanism.

The High-Temperature Requirement

LPCVD relies on high temperatures to provide the activation energy for the surface chemical reactions. This makes it unsuitable for depositing films on temperature-sensitive materials, such as plastics, or on semiconductor devices that already have low-melting-point metals like aluminum integrated into them.

LPCVD vs. Plasma-Enhanced CVD (PECVD)

To overcome the temperature limitation, Plasma-Enhanced CVD (PECVD) is often used. PECVD uses an electric field to create a plasma, which energizes the precursor gases. This allows deposition to occur at much lower temperatures. The trade-off is that PECVD films are often less dense, less uniform, and have different properties than their high-temperature LPCVD counterparts.

LPCVD vs. Physical Vapor Deposition (PVD)

Physical Vapor Deposition (PVD), such as sputtering, is a fundamentally different process. It is a line-of-sight physical process, not a chemical one. While PVD operates at low temperatures and is excellent for depositing metals and alloys, it struggles to produce the highly conformal coatings that LPCVD excels at.

Making the Right Choice for Your Goal

Selecting a deposition method requires aligning the process capabilities with your primary objective for the thin film.

- If your primary focus is ultimate film purity and uniformity over complex 3D structures: LPCVD is the industry standard, provided your substrate can withstand the high processing temperatures.

- If your primary focus is depositing a film on a temperature-sensitive substrate: PECVD is the logical alternative, accepting a potential trade-off in film quality compared to LPCVD.

- If your primary focus is depositing a pure metal or alloy with good adhesion at low temperatures: PVD methods like sputtering are generally the superior and more direct choice.

Ultimately, choosing the right deposition technology depends on a clear understanding of your material, thermal, and geometric constraints.

Summary Table:

| Key Aspect | LPCVD Characteristic |

|---|---|

| Process Type | Chemical vapor deposition under vacuum |

| Primary Advantage | Exceptional film conformality and uniformity |

| Operating Temperature | High (500-900°C) |

| Best For | Temperature-resistant substrates requiring high-purity coatings |

| Alternative for Low Temp | Plasma-Enhanced CVD (PECVD) |

Ready to achieve superior thin film quality in your lab? KINTEK specializes in lab equipment and consumables, providing solutions for precise deposition processes like LPCVD. Whether you're developing microelectronics or high-performance materials, our expertise ensures you get the right equipment for exceptional results. Contact our experts today to discuss your specific application needs!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition