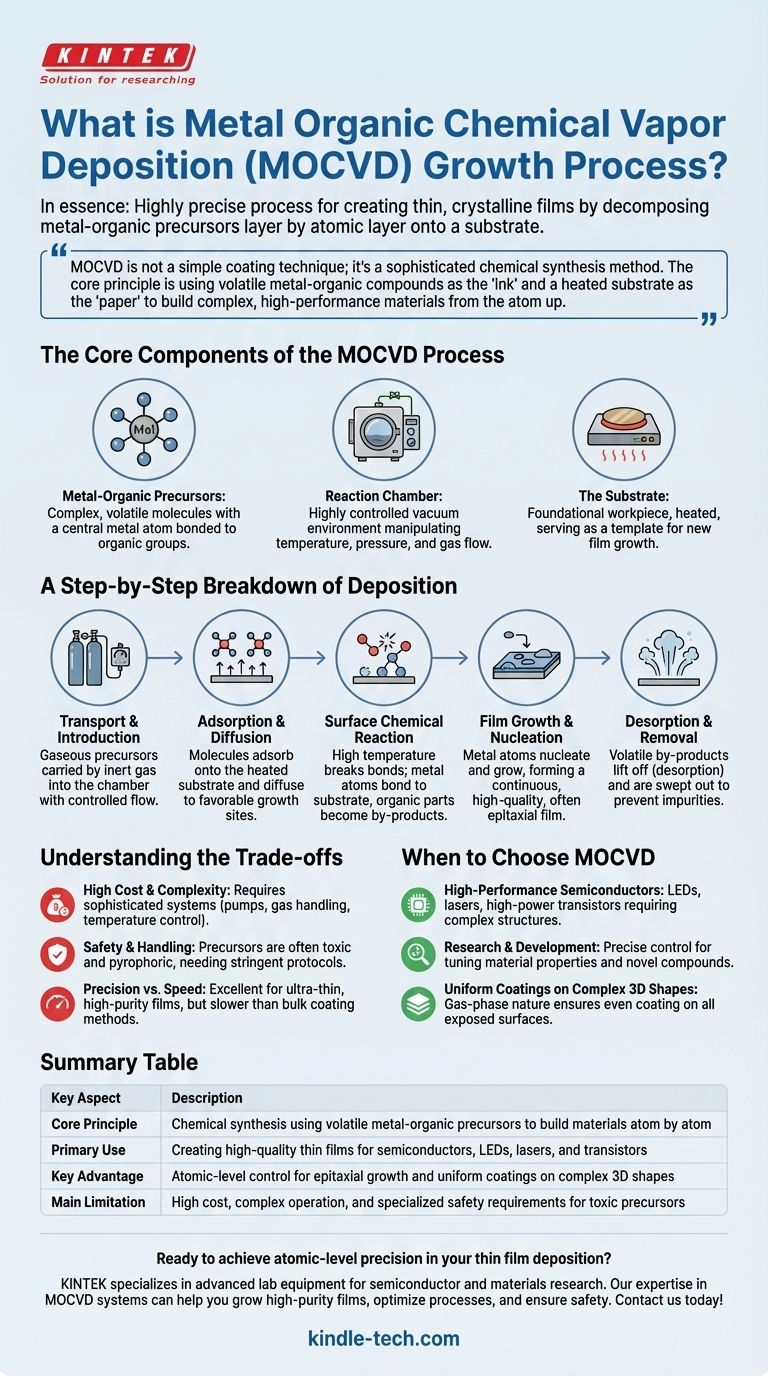

In essence, Metal-Organic Chemical Vapor Deposition (MOCVD) is a highly precise process for creating thin, crystalline films on a surface. It involves introducing specific chemical vapors, known as metal-organic precursors, into a reaction chamber where they decompose with heat and deposit a high-quality solid material, layer by atomic layer, onto a substrate.

MOCVD is not a simple coating technique; it's a sophisticated chemical synthesis method. The core principle is using volatile metal-organic compounds as the "ink" and a heated substrate as the "paper" to build complex, high-performance materials from the atom up.

The Core Components of the MOCVD Process

To understand how MOCVD works, you must first understand its three essential components. Each plays a critical and distinct role in the final outcome.

The Metal-Organic Precursors

The defining feature of MOCVD is its use of metal-organic precursors. These are complex molecules where a central metal atom is bonded to organic groups.

These molecules are engineered to be volatile, meaning they turn into a gas at relatively low temperatures without breaking down. This allows them to be transported into the reaction chamber easily.

The Reaction Chamber

This is a highly controlled environment, typically held under vacuum. The chamber allows for precise manipulation of temperature, pressure, and gas flow rates.

The substrate, which is the material to be coated, is placed inside this chamber and heated to a specific reaction temperature.

The Substrate

The substrate is the foundational workpiece upon which the new material is grown. Its own crystal structure and surface quality are critical, as they often serve as a template for the new film.

A Step-by-Step Breakdown of Deposition

The MOCVD growth process is a sequential chain of physical and chemical events that must occur in perfect order to create a high-quality film.

Transport and Introduction

The metal-organic precursors, now in a gaseous state, are carried into the reaction chamber by an inert carrier gas (like hydrogen or nitrogen). Their flow rates are meticulously controlled.

Adsorption and Diffusion

Once inside the chamber, the precursor gas molecules travel to the heated substrate and stick to its surface in a process called adsorption.

These adsorbed molecules can then diffuse, or move across the surface, to find energetically favorable locations for growth, such as an existing step in the crystal lattice.

Surface Chemical Reaction

This is the core of the process. The high temperature of the substrate provides the energy needed to break the chemical bonds within the precursor molecules.

The metal atoms detach from their organic components and bond to the substrate. The organic components are now considered by-products.

Film Growth and Nucleation

The deposited metal atoms link together, forming stable islands that nucleate and grow. Over time, these islands coalesce to form a continuous, thin film.

By carefully controlling the conditions, this growth can be epitaxial, meaning the new film's crystal structure is a perfect extension of the underlying substrate's structure.

Desorption and Removal

The volatile organic by-products that were cleaved from the precursors lift off the surface (desorption) and are swept out of the reaction chamber by the gas flow.

This continuous removal is crucial to prevent impurities from being incorporated into the growing film.

Understanding the Trade-offs

While powerful, MOCVD is a specialized technique with significant operational considerations. Understanding its limitations is key to its proper application.

High Cost and Complexity

MOCVD systems are highly complex and expensive. They require sophisticated vacuum pumps, gas handling systems for multiple precursors, and precise temperature control units.

Safety and Handling

The metal-organic precursors are often highly toxic and pyrophoric, meaning they can spontaneously ignite upon contact with air. This necessitates stringent safety protocols and specialized handling equipment.

Precision vs. Speed

MOCVD excels at creating ultra-thin, high-purity films with atomic-level control. However, it can be a relatively slow deposition process compared to other methods designed for producing thick, bulk coatings. Its strength is in quality, not quantity.

When to Choose MOCVD

The decision to use MOCVD is driven entirely by the final material requirements. It is a tool for applications where crystalline quality and compositional control are paramount.

- If your primary focus is manufacturing high-performance semiconductors: MOCVD is the industry standard for creating the complex, layered crystal structures required for LEDs, lasers, and high-power transistors.

- If your primary focus is research and development of novel materials: The precise control over gas flow and temperature makes MOCVD ideal for tuning material properties and creating experimental compounds.

- If your primary focus is achieving uniform coatings on complex 3D shapes: MOCVD's gas-phase nature ensures that all exposed surfaces are coated evenly, unlike line-of-sight physical deposition methods.

Ultimately, MOCVD is the essential tool for building the foundational materials of our modern technological world.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Chemical synthesis using volatile metal-organic precursors to build materials atom by atom |

| Primary Use | Creating high-quality thin films for semiconductors, LEDs, lasers, and transistors |

| Key Advantage | Atomic-level control for epitaxial growth and uniform coatings on complex 3D shapes |

| Main Limitation | High cost, complex operation, and specialized safety requirements for toxic precursors |

Ready to achieve atomic-level precision in your thin film deposition?

KINTEK specializes in advanced lab equipment and consumables for semiconductor and materials research. Our expertise in MOCVD systems can help you:

- Grow high-purity crystalline films with exceptional uniformity

- Optimize your deposition process for LEDs, lasers, and semiconductor devices

- Ensure safe handling of specialized precursors and gases

Let our team provide the right equipment and support for your laboratory's thin film deposition needs. Contact us today to discuss how we can enhance your research and manufacturing capabilities!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition