In the world of advanced materials, Microwave Plasma Chemical Vapor Deposition (MPCVD) is a sophisticated process for growing high-purity crystals and thin films. It functions by using microwave energy to excite a gas mixture into a plasma state within a vacuum chamber. Reactive species from this plasma then settle onto a substrate, building up a crystalline material, most famously lab-grown diamonds, layer by layer.

While traditional methods often rely on brute force—immense pressure and heat—to create materials, MPCVD offers a more elegant, low-pressure approach. It uses the precision of microwave-generated plasma to "grow" materials like flawless diamonds with exceptional control and purity.

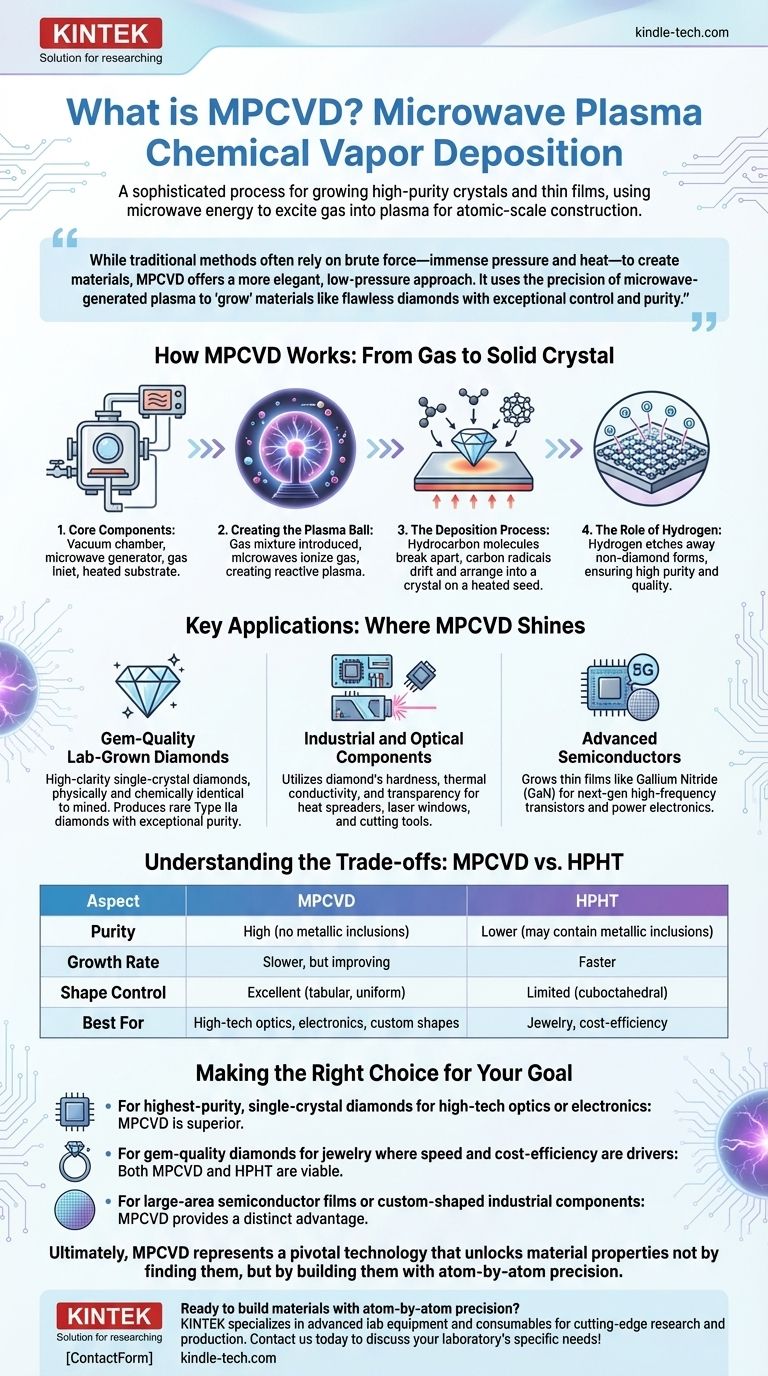

How MPCVD Works: From Gas to Solid Crystal

MPCVD is a process of atomic-scale construction. It doesn't compress existing material; it builds new material from gaseous precursors.

The Core Components

An MPCVD system consists of a vacuum chamber, a microwave generator (like a magnetron), a gas inlet system, and a stage to hold and heat a substrate. These components work in concert to create a highly controlled growth environment.

Creating the Plasma Ball

The process begins by introducing a precise mixture of gases, such as methane and hydrogen for diamond growth, into the low-pressure chamber. Microwaves are then directed into the chamber, energizing the gas and stripping electrons from the atoms. This creates a plasma—a glowing ball of superheated, chemically reactive ions and radicals.

The Deposition Process

Inside this plasma, hydrocarbon molecules break apart. Carbon radicals then drift down and land on a heated substrate, which is often a tiny, pre-existing diamond "seed." Under carefully managed conditions, these carbon atoms arrange themselves into the diamond crystal lattice, growing the seed into a larger, high-quality diamond.

The Role of Hydrogen

Hydrogen gas plays a critical role beyond just being part of the plasma. It selectively etches away any non-diamond carbon (like graphite) that might try to form on the substrate. This continuous cleaning action is key to ensuring the final crystal is of exceptionally high purity and quality.

Key Applications: Where MPCVD Shines

The unique control offered by MPCVD makes it the preferred method for applications where material perfection is paramount.

Gem-Quality Lab-Grown Diamonds

This is MPCVD's most well-known application. The process allows for the growth of large, high-clarity single-crystal diamonds that are physically and chemically identical to mined diamonds. It can produce Type IIa diamonds, a category known for exceptional purity that makes up less than 2% of natural diamonds.

Industrial and Optical Components

The extreme properties of diamond—hardness, thermal conductivity, and optical transparency—make it a super-material. MPCVD is used to create diamond heat spreaders for cooling high-power electronics, durable windows for lasers and industrial sensors, and ultra-sharp cutting tools.

Advanced Semiconductors

MPCVD is not limited to diamond. It is also used to grow thin films of other advanced materials like Gallium Nitride (GaN). These wide-bandgap semiconductors are essential for creating next-generation high-frequency, high-power transistors used in 5G communications and efficient power electronics.

Understanding the Trade-offs: MPCVD vs. HPHT

MPCVD is one of two primary methods for diamond synthesis. The other is High-Pressure High-Temperature (HPHT), which mimics the natural diamond formation process.

Quality and Purity

MPCVD typically produces diamonds with higher purity and fewer structural defects than HPHT. Because it doesn't use the metal catalysts required by HPHT, MPCVD diamonds are free from metallic inclusions. This leads to superior optical and thermal properties.

Growth Rate

The primary advantage of HPHT is speed. The HPHT process can often grow diamonds faster than MPCVD. However, advancements in MPCVD technology are continually closing this gap.

Control and Shape

MPCVD offers unparalleled control over the growth process, allowing for the creation of uniform, large-area sheets or precisely shaped crystals. HPHT growth is often confined to a cuboctahedral shape, whereas MPCVD growth is tabular, making it more efficient for producing plates needed for electronics or optics.

Making the Right Choice for Your Goal

The choice between synthesis methods is driven entirely by the final application and its specific performance requirements.

- If your primary focus is producing the highest-purity, single-crystal diamonds for high-tech optics or electronics: MPCVD is the superior choice due to its exceptional process control and low contamination.

- If your primary focus is producing gem-quality diamonds for jewelry where speed and cost-efficiency are drivers: Both MPCVD and HPHT are viable, with the choice often depending on the specific manufacturer's technology and scale.

- If your primary focus is creating large-area semiconductor films or custom-shaped industrial components: MPCVD's tabular growth and process control provide a distinct advantage over HPHT.

Ultimately, MPCVD represents a pivotal technology that unlocks material properties not by finding them, but by building them with atom-by-atom precision.

Summary Table:

| Aspect | MPCVD | HPHT |

|---|---|---|

| Purity | High (no metallic inclusions) | Lower (may contain metallic inclusions) |

| Growth Rate | Slower, but improving | Faster |

| Shape Control | Excellent (tabular, uniform) | Limited (cuboctahedral) |

| Best For | High-tech optics, electronics, custom shapes | Jewelry, cost-efficiency |

Ready to build materials with atom-by-atom precision? KINTEK specializes in advanced lab equipment and consumables for cutting-edge research and production. Whether you're growing high-purity diamonds for optics or developing next-generation semiconductors, our expertise and solutions can help you achieve superior results. Contact us today to discuss how we can support your laboratory's specific needs!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- How are CVD lab diamonds made? Discover the Science Behind Lab-Grown Gems

- How long do lab-grown diamonds take to make? A 6-8 Week Journey from Seed to Gem

- Are CVD diamonds worth it? Unlock Brilliant Value & Ethical Clarity

- Are artificial diamonds as strong as natural diamonds? Discover the Truth About Lab-Grown Diamond Durability

- What is MP CVD? Unlock the Power of Microwave Plasma for High-Purity Diamond Synthesis

- What is a CVD diamond machine? Unlock the Power of Lab-Grown Diamond Engineering

- What do you need to grow lab diamonds? Carbon, Seed, and Immense Energy Explained

- What specific advantages does the MPCVD method have for preparing diamond films? Achieve High-Purity Synthesis