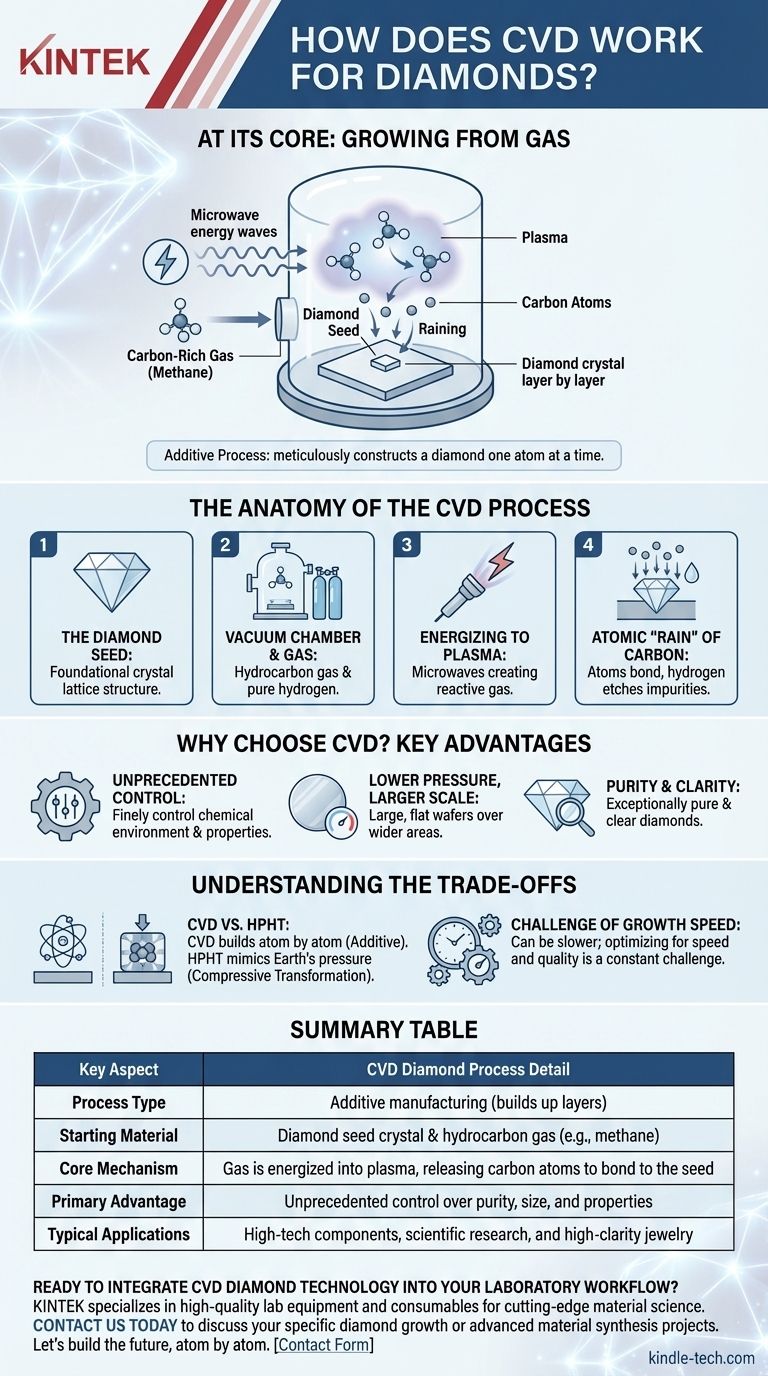

At its core, Chemical Vapor Deposition (CVD) for diamonds is a process of "growing" a diamond from a gas. It involves placing a tiny diamond "seed" into a vacuum chamber, introducing a carbon-rich gas like methane, and using energy to break that gas down. This causes carbon atoms to fall and attach to the seed, building up a new, larger diamond layer by layer.

Unlike methods that mimic the Earth's high pressure, CVD is an additive process. It doesn't compress carbon into a diamond; it meticulously constructs a diamond one atom at a time, offering remarkable control over the final product.

The Anatomy of the CVD Process

To truly understand CVD, it's best to think of it as a highly controlled, atomic-level construction project. The process unfolds in a specific sequence inside a specialized reactor.

The Diamond Seed

The entire process begins with a substrate, which is typically a very thin, high-quality slice of an existing diamond. This diamond seed provides the foundational crystal lattice structure upon which the new diamond will grow.

The Vacuum Chamber and Gaseous Mixture

The seed is placed inside a sealed chamber, and a vacuum is created. Then, a precise mixture of gases is introduced. This is almost always a hydrocarbon gas (like methane, which is rich in carbon) and pure hydrogen.

Energizing the Gas into Plasma

This is the critical step. The chamber is flooded with energy, typically from microwaves, which heats the gases to extreme temperatures. This intense energy strips the molecules apart, creating a glowing cloud of chemically reactive gas known as plasma.

An Atomic "Rain" of Carbon

Within the plasma, the methane molecules (CH₄) are broken down, releasing individual carbon atoms. These carbon atoms "rain" down onto the cooler diamond seed below.

Crucially, they bond to the seed's surface, extending its perfect crystal lattice. The hydrogen gas plays a vital role by etching away any carbon that doesn't form a proper diamond bond, ensuring the purity of the growing crystal.

Why Choose CVD? Key Advantages

The CVD method has become a focus of intensive research because it offers distinct advantages over other techniques, particularly the High-Pressure, High-Temperature (HPHT) method.

Unprecedented Control

Because CVD is an additive process, scientists can finely control the chemical environment. This allows for precise management of impurities and the ability to grow diamonds with specific properties required for advanced industrial or technological applications.

Lower Pressure, Larger Scale

CVD operates at very low pressures, typically below one-tenth of the Earth's atmospheric pressure. This avoids the immense machinery required for HPHT and allows for the growth of large, flat diamond wafers over wider areas than is possible with pressure-based methods.

Purity and Clarity

The continuous etching action of the hydrogen gas during the process helps remove defects and non-diamond carbon forms, like graphite. This contributes to the creation of exceptionally pure and clear diamonds, which are highly sought after for both jewelry and science.

Understanding the Trade-offs

No single method is universally superior; each has its own context and challenges. Objectivity requires understanding where CVD stands in relation to other methods.

CVD vs. HPHT

The fundamental difference is in the starting material and the process. CVD builds a diamond from a gas, atom by atom. HPHT mimics the Earth's geology, taking a solid carbon source (like graphite) and subjecting it to immense pressure and heat to force a transformation.

The Challenge of Growth Speed

While highly controlled, the CVD process can be slower than HPHT. The meticulous, layer-by-layer growth requires time, and optimizing for both speed and quality is a constant engineering challenge.

Post-Growth Treatments

Some CVD-grown diamonds, particularly those intended for use in jewelry, may undergo post-growth treatments. These processes, such as heating, can be used to permanently improve the diamond's color and are a standard part of the production cycle for many labs.

Making the Right Choice for Your Goal

Understanding the process empowers you to evaluate the final product based on your specific needs.

- If your primary focus is advanced technology: CVD is often superior due to its ability to create large wafers and precisely control the diamond's electronic and optical properties.

- If your primary focus is jewelry: Both CVD and HPHT produce chemically and physically real diamonds; CVD is renowned for its potential to grow large, high-clarity (Type IIa) stones that are very rare in nature.

- If your primary focus is scientific understanding: The key distinction is that CVD is an "additive manufacturing" process at the atomic level, while HPHT is a "compressive transformation" process.

Ultimately, knowing how a CVD diamond is made demystifies its origin and confirms its identity as a true diamond, defined by its atomic structure, not its point of creation.

Summary Table:

| Key Aspect | CVD Diamond Process Detail |

|---|---|

| Process Type | Additive manufacturing (builds up layers) |

| Starting Material | Diamond seed crystal & hydrocarbon gas (e.g., methane) |

| Core Mechanism | Gas is energized into plasma, releasing carbon atoms to bond to the seed |

| Primary Advantage | Unprecedented control over purity, size, and properties |

| Typical Applications | High-tech components, scientific research, and high-clarity jewelry |

Ready to Integrate CVD Diamond Technology into Your Laboratory Workflow?

The precise, controlled nature of Chemical Vapor Deposition is key to advancing research and development in fields from semiconductors to optics. KINTEK specializes in providing the high-quality lab equipment and consumables necessary for cutting-edge material science.

Contact us today using the form below to discuss how our solutions can support your specific diamond growth or advanced material synthesis projects. Let's build the future, atom by atom.

Visual Guide

Related Products

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- Are CVD diamonds fake? Discover the Truth About Lab-Grown Diamonds

- How is a CVD diamond formed? A Guide to Lab-Grown Diamond Creation

- How much cheaper are CVD diamonds? Save 20-30% on a Genuine Diamond

- What are the uses of diamond in industry? Solving Extreme Engineering Challenges

- Can a diamond be created in a laboratory? The Science Behind Genuine Lab-Grown Diamonds

- Do lab-grown diamonds last as long? Yes, They Offer the Same Unmatched Durability

- What is MPCVD method? A Guide to High-Purity Diamond Synthesis

- What is the difference between CVD diamond and natural diamond? A Guide to Making an Informed Choice