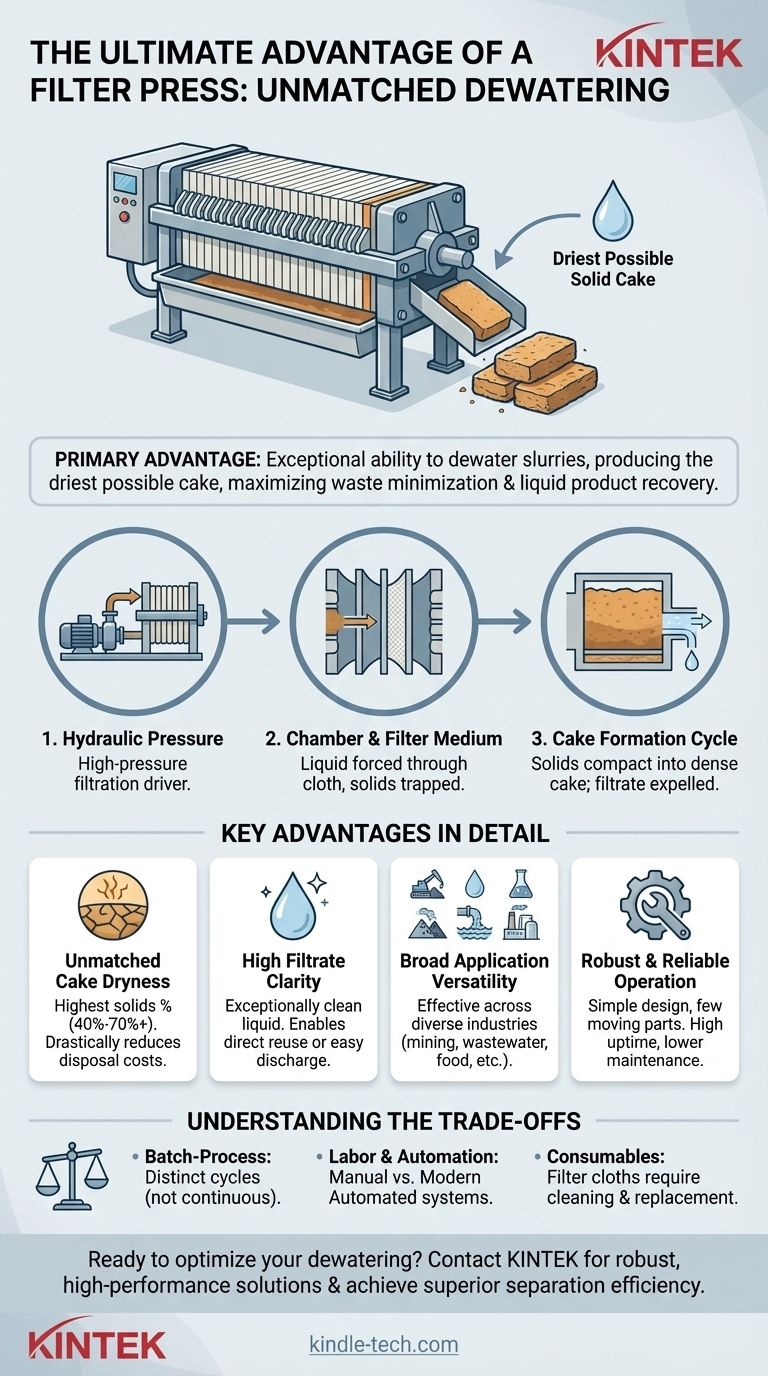

The primary advantage of a filter press is its exceptional ability to dewater slurries, producing the driest possible solid cake compared to other mechanical separation methods. This high level of efficiency in solid-liquid separation translates directly into significant operational benefits, particularly in waste minimization and liquid product recovery.

While many technologies can separate solids from liquids, the filter press is engineered for one ultimate goal: maximum dewatering. Its true value isn't just in filtration, but in its power to drastically reduce the final volume of solid waste, which directly cuts disposal costs and maximizes the recovery of valuable filtrate.

How a Filter Press Achieves Superior Dewatering

Understanding the operational principle of a filter press reveals why it is so effective. The process is a straightforward application of high-pressure filtration.

The Core Principle: Hydraulic Pressure

A filter press operates by pumping a slurry (a mixture of solids and liquids) into a series of sealed chambers under high pressure. This hydraulic force is the key driver of the entire separation process.

The Chamber and Filter Medium

Each chamber is formed by two recessed filter plates, which are lined with a filter cloth. This cloth acts as the filter medium. Under pressure, the liquid is forced through the pores of the cloth, while the solid particles are trapped and begin to accumulate inside the chamber.

The Cake Formation Cycle

As more slurry is pumped in, the captured solids build upon each other, forming a dense, compacted "filter cake." This process continues until the chamber is completely full of dewatered solids and the liquid—now called filtrate—has been expelled through ports in the filter plates.

Key Advantages in Detail

The simple, high-pressure mechanism of a filter press gives rise to several distinct and powerful advantages for industrial processes.

Unmatched Cake Dryness

This is the most critical benefit. A filter press consistently achieves the highest percentage of solids in its final cake, often ranging from 40% to over 70% solids by weight. This is significantly drier than what can be achieved with centrifuges or belt presses.

A drier cake means less water weight, which drastically reduces the cost of transportation and disposal for waste materials.

High Filtrate Clarity

The liquid that passes through the filter cloth is exceptionally clean. The tightly woven cloth and the cake itself act as a deep and effective filter, resulting in a high-quality filtrate that can often be reused directly in the plant's process or discharged with minimal further treatment.

Broad Application Versatility

The fundamental principle of pressure filtration is effective across an enormous range of materials and industries. Filter presses are successfully used in municipal wastewater treatment, chemical manufacturing, mining operations, food and beverage processing, and pharmaceuticals.

Robust and Reliable Operation

Filter presses are mechanically simple machines with very few moving parts. This robust design leads to high operational uptime, lower maintenance requirements, and a very long service life compared to more complex rotational equipment like centrifuges.

Understanding the Trade-offs

No technology is perfect for every scenario. The primary trade-off of a filter press is its operational nature.

Batch vs. Continuous Operation

A filter press is a batch-process machine. It has a distinct cycle: fill, press, open, discharge cake, and close. This is different from systems like belt presses or centrifuges, which operate continuously. For extremely high and constant flow rates, a continuous system might be more suitable.

Labor and Automation Considerations

Older, manual filter presses can be labor-intensive, as they require an operator to physically separate the plates and ensure the cake is discharged. However, modern filter presses are highly automated, with features like automatic plate shifters and cake discharge mechanisms that significantly reduce labor needs.

Consumable Components

The filter cloths are a critical component and a consumable item. They require periodic cleaning to maintain performance and will eventually need to be replaced. This represents an ongoing operational cost that must be factored into any analysis.

Making the Right Choice for Your Process

To determine if a filter press is the optimal solution, consider your primary operational goal.

- If your primary focus is minimizing disposal costs: The filter press is almost always the superior choice due to its ability to produce the driest possible cake, directly reducing the tonnage you pay to haul away.

- If your primary focus is recovering a valuable liquid product: The exceptional filtrate clarity and high recovery rate make the filter press a leading contender for maximizing product yield.

- If your primary focus is processing a very high, uninterrupted flow: You should carefully evaluate the cycle time of an appropriately sized batch filter press against the capabilities of a continuous system.

Ultimately, the advantage of a filter press lies in its unparalleled dewatering performance, offering a robust and highly effective solution for achieving maximum solid-liquid separation.

Summary Table:

| Key Advantage | Impact |

|---|---|

| Unmatched Cake Dryness | Reduces waste volume and disposal costs significantly (40-70% solids). |

| High Filtrate Clarity | Enables filtrate reuse or easy discharge, improving process efficiency. |

| Broad Application Versatility | Suitable for mining, wastewater, chemical, food & beverage, and more. |

| Robust & Reliable Operation | Fewer moving parts mean lower maintenance and longer service life. |

Ready to optimize your dewatering process and cut costs?

At KINTEK, we specialize in providing robust, high-performance filter presses and lab equipment tailored to your specific industrial or laboratory needs. Whether you're in mining, wastewater treatment, or chemical processing, our solutions are designed to maximize solid recovery, minimize waste, and deliver exceptional filtrate clarity.

Let our experts help you achieve superior separation efficiency. Contact us today for a personalized consultation and discover how KINTEK can enhance your operations.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy