The primary advantages of an induction furnace are its unparalleled precision, efficiency, and cleanliness. By generating heat directly within the metal itself through electromagnetic induction, it offers a highly controlled and rapid melting process that avoids the contamination and waste associated with traditional combustion-based methods.

The fundamental advantage of induction heating is not just one feature, but how its core principle—generating heat inside the material—gives rise to a cascade of benefits in process control, material quality, and environmental safety.

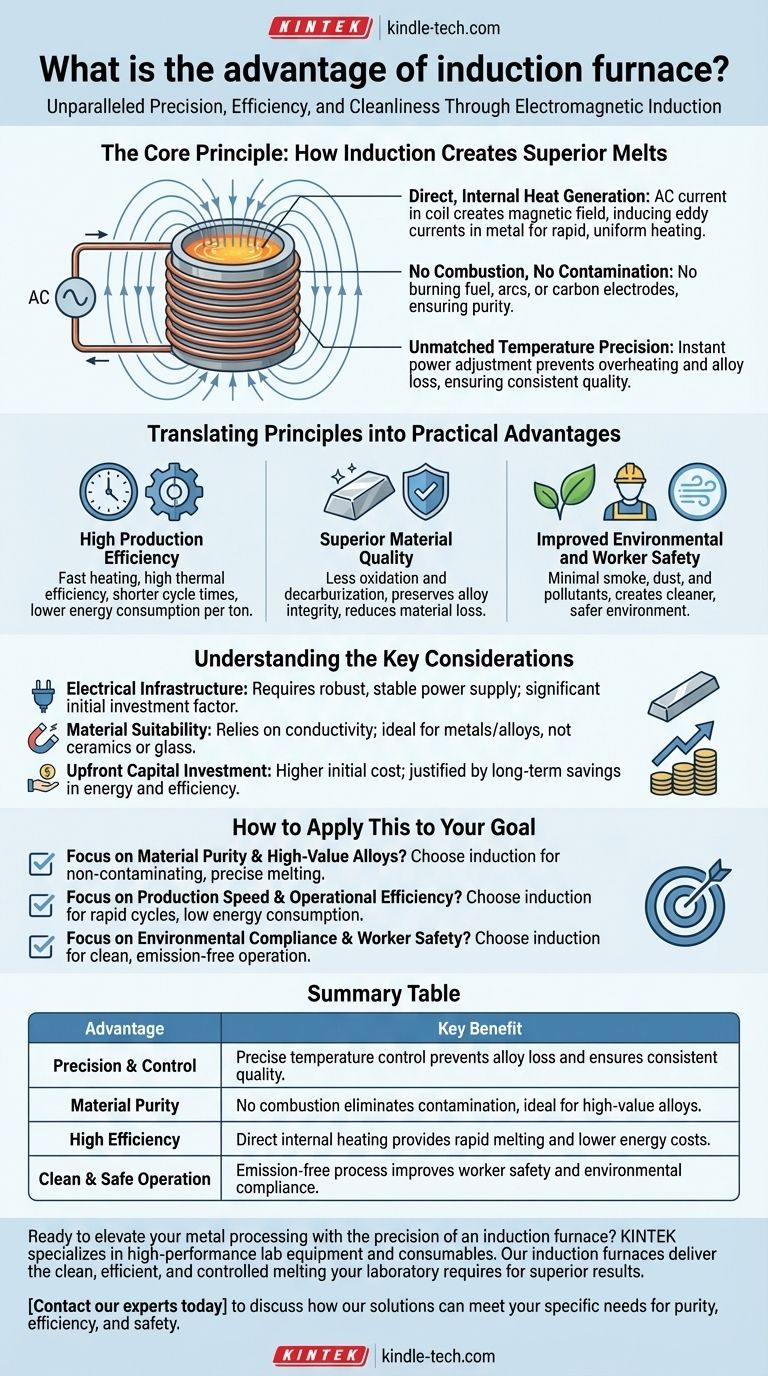

The Core Principle: How Induction Creates Superior Melts

The unique benefits of an induction furnace stem directly from its method of heating. Unlike fuel-fired or arc furnaces that apply external heat, an induction furnace turns the metal charge into its own heat source.

Direct, Internal Heat Generation

An induction furnace uses a powerful alternating current passed through a copper coil to create a strong magnetic field. When a conductive material like metal is placed inside this field, it induces electrical currents (eddy currents) within the metal itself, generating intense heat rapidly and uniformly.

No Combustion, No Contamination

Because heat is generated electromagnetically, there is no need for burning fuel, arcs, or carbon electrodes. This completely eliminates a major source of contamination, ensuring the chemical composition of the melt remains pure. This is critical when working with high-performance alloys where even minor impurities can compromise quality.

Unmatched Temperature Precision

The power supplied to the induction coil can be adjusted instantly and with extreme accuracy. This gives operators precise control over the melting temperature, preventing the overheating that can burn off valuable and expensive alloying elements. The result is less waste and a more consistent, higher-quality final product.

Translating Principles into Practical Advantages

This clean, direct, and controlled heating method delivers significant operational and environmental benefits that are difficult to achieve with other technologies.

High Production Efficiency

Induction furnaces boast a very fast heating speed and high thermal efficiency because the energy is transferred directly to the material being melted. This leads to shorter cycle times, higher throughput, and lower energy consumption per ton of metal produced, directly impacting operational costs.

Superior Material Quality

The absence of combustion gases means there is significantly less oxidation and decarburization of the metal surface. This not only preserves the integrity of the alloy but also reduces material loss, saving costs on both raw materials and subsequent processing.

Improved Environmental and Worker Safety

With no flame or combustion byproducts, induction furnaces produce minimal smoke, dust, and pollutants. This creates a much cleaner and safer working environment for employees and drastically reduces the facility's environmental footprint.

Understanding the Key Considerations

While highly advantageous, no technology is a universal solution. An objective evaluation requires acknowledging its specific operational context.

Electrical Infrastructure

Induction furnaces are powerful electrical devices that require a robust and stable power supply. The cost and availability of this electrical infrastructure can be a significant factor in the initial investment and site selection.

Material Suitability

The principle of induction heating relies on the material being electrically conductive. While this makes it ideal for most metals and alloys, it is not a suitable technology for melting non-conductive materials like ceramics or glass.

Upfront Capital Investment

The sophisticated power electronics and precision-engineered coils can make the initial purchase price of an induction furnace higher than some traditional furnace types. However, this cost is often justified by long-term savings in energy, materials, and production efficiency.

How to Apply This to Your Goal

Your choice of furnace technology should be driven by the specific demands of your application and your primary business drivers.

- If your primary focus is material purity and high-value alloys: The non-contaminating and precise nature of induction melting makes it the superior choice.

- If your primary focus is production speed and operational efficiency: The rapid heating cycles and low energy consumption offer a clear path to lower costs and higher output.

- If your primary focus is environmental compliance and worker safety: The clean, emission-free operation of an induction furnace is a significant advantage over combustion-based alternatives.

Ultimately, choosing an induction furnace is an investment in control, quality, and efficiency for modern metal processing.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Precision & Control | Precise temperature control prevents alloy loss and ensures consistent quality. |

| Material Purity | No combustion eliminates contamination, ideal for high-value alloys. |

| High Efficiency | Direct internal heating provides rapid melting and lower energy costs. |

| Clean & Safe Operation | Emission-free process improves worker safety and environmental compliance. |

Ready to elevate your metal processing with the precision of an induction furnace?

KINTEK specializes in high-performance lab equipment and consumables. Our induction furnaces are designed to deliver the clean, efficient, and controlled melting your laboratory requires for superior results.

Contact our experts today to discuss how our solutions can meet your specific needs for purity, efficiency, and safety.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys