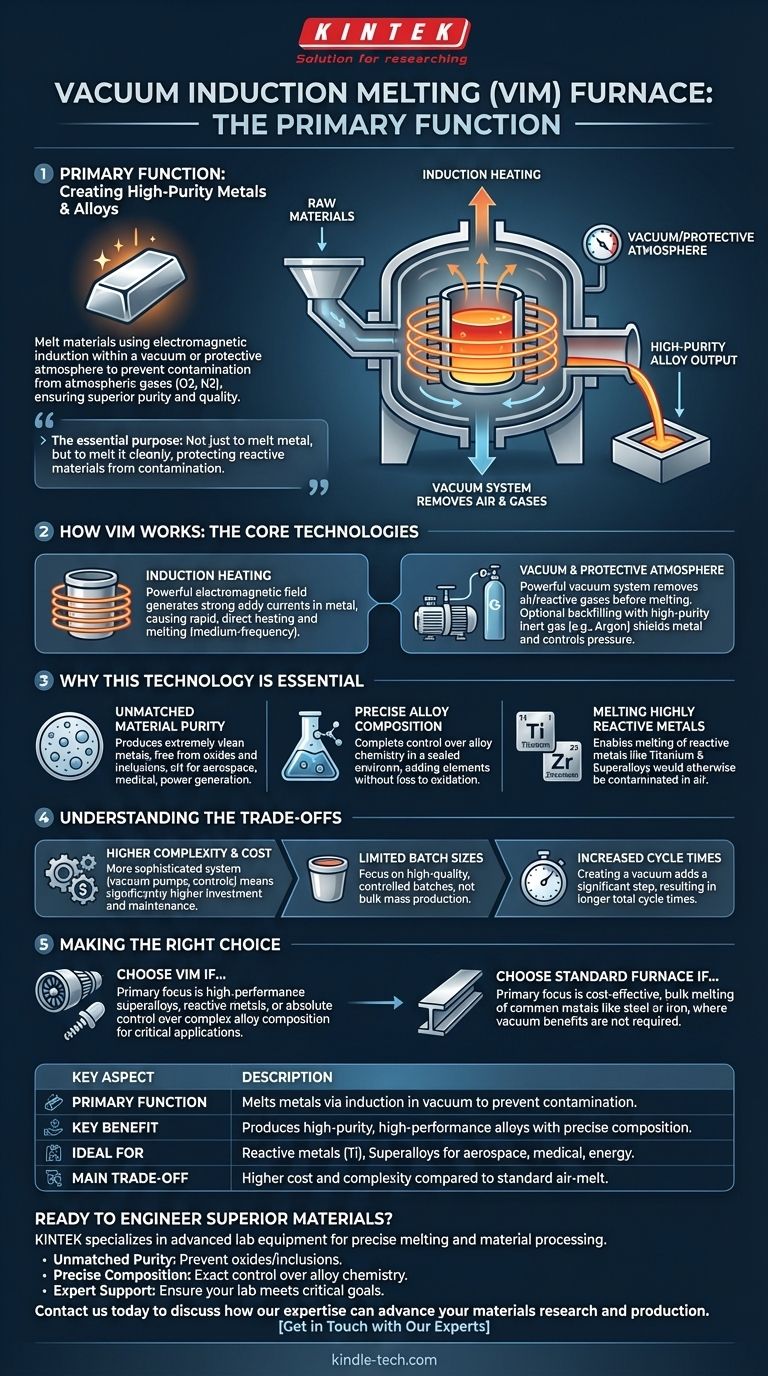

At its core, a vacuum induction melting (VIM) furnace is a specialized tool for creating high-purity metals and alloys. Its primary function is to melt materials using electromagnetic induction within a vacuum or a controlled, protective atmosphere. This process is specifically designed to prevent the molten metal from reacting with atmospheric gases like oxygen and nitrogen, which would otherwise introduce impurities and degrade the material's quality.

The essential purpose of a VIM furnace is not just to melt metal, but to melt it cleanly. The vacuum environment is the critical feature, protecting reactive materials from contamination to produce alloys with superior purity, precise composition, and enhanced performance characteristics.

How Vacuum Induction Melting Works

The VIM process combines two core technologies—induction heating and vacuum chambers—to achieve its unique results. Understanding how these elements work together reveals why this furnace is critical for advanced materials.

The Principle of Induction Heating

A VIM furnace uses a powerful electromagnetic field generated by a coil (the inductor). This field induces strong electrical eddy currents directly within the metal placed inside a crucible. The metal's own electrical resistance causes it to heat up rapidly and melt, a process known as medium-frequency induction heating.

The Critical Role of the Vacuum

Before melting begins, a powerful vacuum system removes the air from the melting chamber. This eliminates reactive gases, primarily oxygen and nitrogen, which are detrimental to many advanced alloys. By melting in a vacuum, the process prevents the formation of oxides and nitrides, which are common impurities (inclusions) that can compromise a material's strength and reliability.

The Protective Atmosphere Option

In some cases, after creating a vacuum, the furnace can be backfilled with a high-purity inert gas, such as argon. This protective atmosphere serves the same purpose as the vacuum: it shields the molten metal from contamination while allowing for precise pressure control during the melting and casting process.

Why This Technology is Essential

The unique capabilities of a VIM furnace make it indispensable for manufacturing materials where performance and reliability are non-negotiable. The benefits stem directly from its controlled environment.

Achieving Unmatched Material Purity

The single most important advantage is the production of extremely clean metals. For applications in aerospace, medical implants, or power generation, even microscopic impurities can lead to catastrophic failure. VIM ensures the final product is free from the oxides and inclusions that form during conventional air-melting.

Enabling Precise Alloy Composition

In a sealed vacuum chamber, metallurgists have complete control over the alloy's chemistry. Alloying elements can be added in precise amounts without the risk of them being lost to oxidation. This allows for the creation of complex superalloys with exact compositions tailored for extreme performance.

Melting Highly Reactive Metals

Metals like titanium, zirconium, and various superalloys have a strong affinity for oxygen and nitrogen. Attempting to melt them in air is impractical, as they would be immediately and severely contaminated. The VIM furnace is one of the few methods capable of melting these reactive materials while preserving their desired properties.

Understanding the Trade-offs

While powerful, the VIM process is a specialized solution with specific constraints. It is not a universal tool for all melting operations.

Higher Complexity and Cost

A VIM furnace is a complete system that includes sophisticated vacuum pumps, high-power electrical supplies, water cooling circuits, and precise control mechanisms. This complexity makes it significantly more expensive to build, operate, and maintain than a standard air-melt furnace.

Limited Batch Sizes

As noted in technical specifications, these furnaces often feature a small melting chamber volume. The focus is on high-quality, controlled batches rather than the mass production of metal. This makes the process suitable for high-value materials, not bulk commodities.

Increased Cycle Times

The necessity of pumping down the chamber to create a vacuum adds a significant step to the overall process. This means the total cycle time—from loading the raw material to pouring the final product—is typically longer than that of a simpler furnace.

Making the Right Choice for Your Goal

Selecting a VIM furnace is a strategic decision driven entirely by the required quality of the end material.

- If your primary focus is producing high-performance superalloys or reactive metals: A VIM furnace is essential to prevent contamination and achieve the required chemical purity and mechanical properties for critical applications.

- If your primary focus is absolute control over a complex alloy's final composition: The sealed, oxygen-free environment of a VIM furnace provides the necessary precision that is impossible to achieve in an open-air furnace.

- If your primary focus is cost-effective, bulk melting of common metals like steel or iron: A standard induction or arc furnace is a far more practical and economical choice, as the benefits of a vacuum environment are not required.

Ultimately, a vacuum induction furnace is chosen not just to melt metal, but to engineer materials with the highest possible degree of purity and control.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Melts metals using induction heating within a vacuum to prevent contamination. |

| Key Benefit | Produces high-purity, high-performance alloys with precise chemical composition. |

| Ideal For | Reactive metals (titanium), superalloys for aerospace, medical, and energy applications. |

| Main Trade-off | Higher cost and complexity compared to standard air-melting furnaces. |

Ready to Engineer Superior Materials?

If your goal is to produce high-purity metals and complex alloys free from contamination, the controlled environment of a vacuum induction melting furnace is essential. KINTEK specializes in advanced lab equipment, including solutions for precise melting and material processing.

We help you achieve:

- Unmatched Purity: Prevent oxides and inclusions to enhance material strength and reliability.

- Precise Composition: Gain exact control over alloy chemistry for specialized applications.

- Expert Support: From selection to operation, our team ensures your lab meets its critical performance goals.

Contact us today to discuss how our expertise can advance your materials research and production. Get in Touch with Our Experts

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What are the applications of coreless type induction furnace? Unlock Clean, Precise Metal Melting

- Can an induction coil melt steel? Unlock Fast, Efficient Industrial Melting

- What type of lining is needed for induction furnace? Choose the Right Refractory for Your Metal

- How does a melting furnace work? A Deep Dive into Induction and Arc Furnace Technology

- How does a vim furnace work? Achieve Ultimate Purity in High-Performance Metal Melting

- What is an induction furnace made of? A Deep Dive into Its Core Components

- Which is better induction furnace or electric arc furnace? The Ultimate Guide for Your Production Needs

- What is the primary function of a Vacuum Induction Melting Furnace? Ensure High-Purity GH3535 Alloy Ingot Preparation