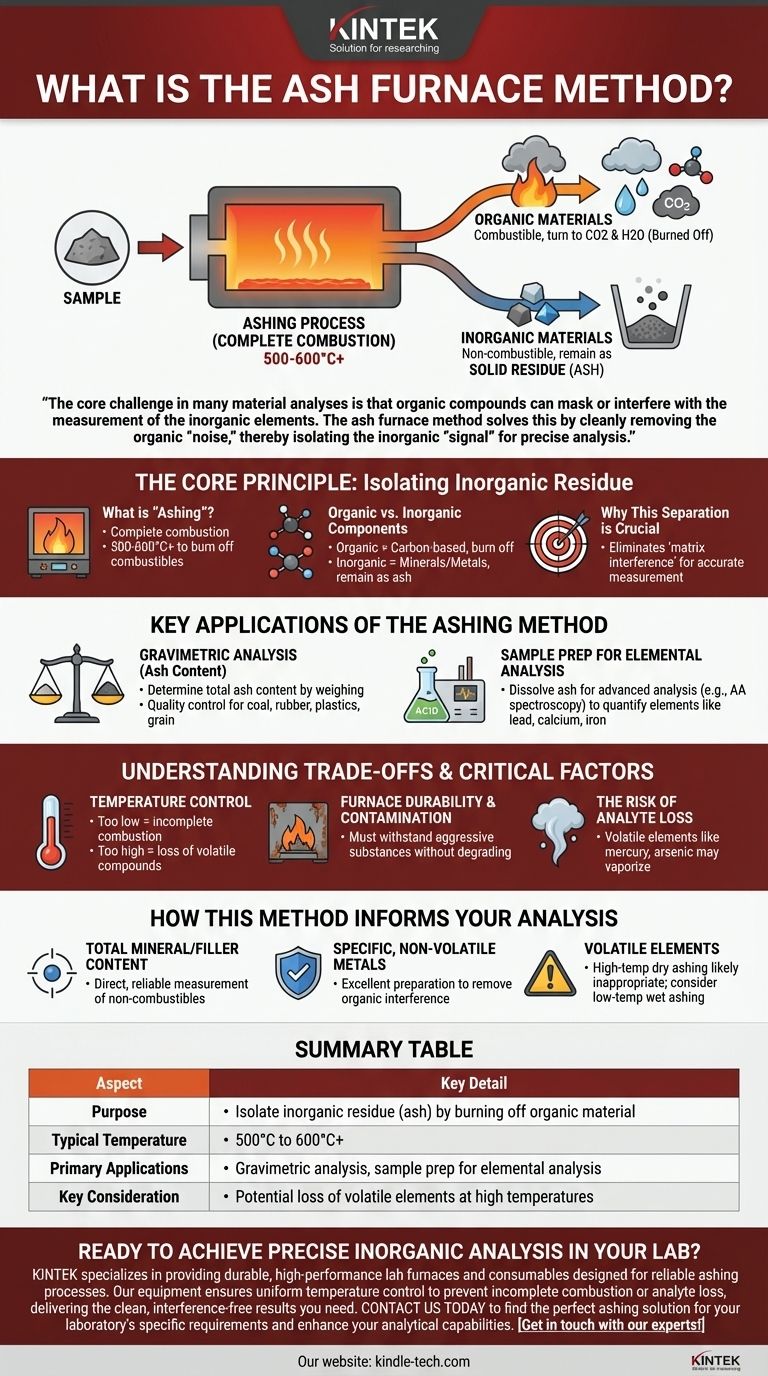

In essence, the ash furnace method is a high-temperature process that uses complete combustion to burn away all organic material from a sample. This procedure is designed to isolate the inorganic, non-combustible components—the "ash"—which can then be accurately weighed or analyzed for their elemental composition.

The core challenge in many material analyses is that organic compounds can mask or interfere with the measurement of the inorganic elements. The ash furnace method solves this by cleanly removing the organic "noise," thereby isolating the inorganic "signal" for precise analysis.

The Core Principle: Isolating the Inorganic Residue

The effectiveness of the ashing method hinges on the fundamental chemical differences between organic and inorganic matter when subjected to extreme heat in the presence of oxygen.

What is "Ashing"?

Ashing is the process of complete combustion. A sample is placed in a specialized furnace and heated to temperatures typically ranging from 500 to 600°C (or higher), allowing all combustible material to burn off completely.

This process is also sometimes referred to as charring, particularly when it serves as a preparatory step in a larger analytical program.

Organic vs. Inorganic Components

Most samples are a mix of organic and inorganic compounds. Organic materials are carbon-based and will combust, turning into carbon dioxide and water vapor. Inorganic materials, such as minerals, salts, and metals, are non-combustible and remain behind as a solid residue.

This remaining residue is the ash. Its weight and composition provide critical information about the original sample.

Why This Separation is Crucial

For many analytical techniques, the large volume of organic material in a sample is simply "matrix interference." It gets in the way of measuring the components of interest.

By eliminating this organic matrix, analysts can prepare a concentrated, clean sample of the inorganic constituents for more accurate and sensitive measurement.

Key Applications of the Ashing Method

The ash furnace method is not an end in itself, but a critical step for various analytical goals across industries like materials science, food science, and environmental testing.

Gravimetric Analysis (Ash Content)

The most direct application is determining a sample's total ash content. By weighing the sample before and after ashing, one can calculate the percentage of non-combustible material.

This is a standard quality control metric for materials like coal, rubber, plastics, and grain.

Sample Preparation for Elemental Analysis

The ash residue is often the starting point for more advanced analysis. The ash can be dissolved in acid and then analyzed using techniques like Atomic Absorption (AA) spectroscopy.

This allows for the precise quantification of specific elements (e.g., lead, calcium, iron) that were present in the original sample, free from organic interference.

Understanding the Trade-offs and Critical Factors

While straightforward in principle, achieving accurate results with an ashing furnace requires careful control and an understanding of its limitations.

The Importance of Temperature Control

An effective ashing furnace must provide a uniform and stable temperature. If the temperature is too low, combustion may be incomplete, leaving behind carbon residue that inflates the final ash weight.

Conversely, if the temperature is too high, some inorganic compounds may become volatile and get lost, leading to an underestimation of the true ash content.

Furnace Durability and Contamination

The combustion process can release aggressive and corrosive substances. The furnace chamber must be constructed from materials that can withstand this chemical attack over time without degrading or introducing contaminants into the sample.

The Risk of Analyte Loss

A primary limitation of this "dry ashing" method is the potential loss of volatile elements. Certain metals and minerals (like mercury, arsenic, and some chlorides) can vaporize at the high temperatures used, meaning they will not be present in the final ash for analysis.

How This Method Informs Your Analysis

Choosing to use the ash furnace method depends entirely on what you need to measure in your sample.

- If your primary focus is determining total mineral or filler content: The ash furnace method provides a direct, reliable measurement of the non-combustible fraction of your material.

- If your primary focus is quantifying specific, non-volatile metals: Ashing serves as an excellent preparation step to remove organic interference before using advanced spectroscopic instruments.

- If your primary focus is analyzing volatile elements: You must recognize that high-temperature dry ashing is likely inappropriate, and a lower-temperature "wet ashing" technique using acids may be required to prevent analyte loss.

Ultimately, the ash furnace method is a foundational technique for simplifying complex samples to reveal their essential inorganic composition.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Purpose | Isolate inorganic residue (ash) by burning off organic material |

| Typical Temperature | 500°C to 600°C+ |

| Primary Applications | Gravimetric analysis (ash content), sample prep for elemental analysis |

| Key Consideration | Potential loss of volatile elements at high temperatures |

Ready to achieve precise inorganic analysis in your lab? The ash furnace method is a cornerstone technique for accurate sample preparation. KINTEK specializes in providing durable, high-performance lab furnaces and consumables designed for reliable ashing processes. Our equipment ensures uniform temperature control to prevent incomplete combustion or analyte loss, delivering the clean, interference-free results you need. Contact us today to find the perfect ashing solution for your laboratory's specific requirements and enhance your analytical capabilities. Get in touch with our experts!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the annealing temperature of quartz? Achieve Optimal Thermal Stability for Your Components

- What is the thermal debinding process? A Guide to Safe Binder Removal for MIM & Ceramics

- What is the use of a digital muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What is the difference between a furnace and an oven in a laboratory? Choose the Right Tool for Your Lab's Heat Needs

- What are the disadvantages of dry ashing? Key Limitations for Accurate Elemental Analysis